Description

Brewhouse system:

As a necessary part of brewing system, Brewhouse takes its responsibility of extracting the matters we need from crashed malt with the help of enzymes. Its structure can be different which depends on the anticipate beer output and how many batches need to be brewed pre day. The one I am gonna show you is the DEGONG‘s15BBL brewhouse which is the first choice for those who want to get up a micro brewery.

15BBL 4-vessel steam heated brewhouse

General technical parameters:

- Structure: Customizable (can be 2-vessel, 3-vessel or 4-vessel which depends)

- Heating method: Steam heating method

- Material: Food grade stainless steel 304

- LED light

- SEW variable frequency drove motors for raker

- Programmable logic controller(PLC) control system for brewhouse system

- Tublar level meter built

- Automatical spent grain discharging

- Automatically controlled pneumatic valves

- Wort pump with variable frequency drove ABB motor

- Skidproof platform

- CIP spraying ball of 360° coverage

- Thickness of inner shell: 3.0mm outer shell: 2.0mm dimple jacket: 1.5mm

- Insulation: PU

Fermentation system:

Fermentation system comprises of fermentation tank, bright beer tank and connecting pipes. After being cooled by plate heating exchanger, the wort is transferred to fermentation tank for fermentation process which is generally consisted of two phases – aerobic respiration and anaerobic respiration. The type of the beer determines the fermentation period. The beer is drinkable after the process.

15BBL fermentation tank

General technical parameters:

- 100% stainless steel 304 TIG welded construction

- 0.4um mirror polish interior finish

- Reinforced stainless steel legs with adjustable height for leveling

- Dual cooling zones – body and cone part

- Design pressure: 3.0 bar Working pressure: 1.5-2 bar

- Perlick type sample valve

- Vacuum relief valve

- Temperature sensor

- Overflow pipe for discharging the foam

- Side manhole

- Dry hopping hole at the top

- All connections are tri-clamp connecting method

- Racking arm with tri-clamp connecting method

- CIP spraying ball with 360° coverage

- Lifting lugs

- Uni-tank option avaible for carbonation stone assembly

- Mechanical regulation valve with pressure gauge

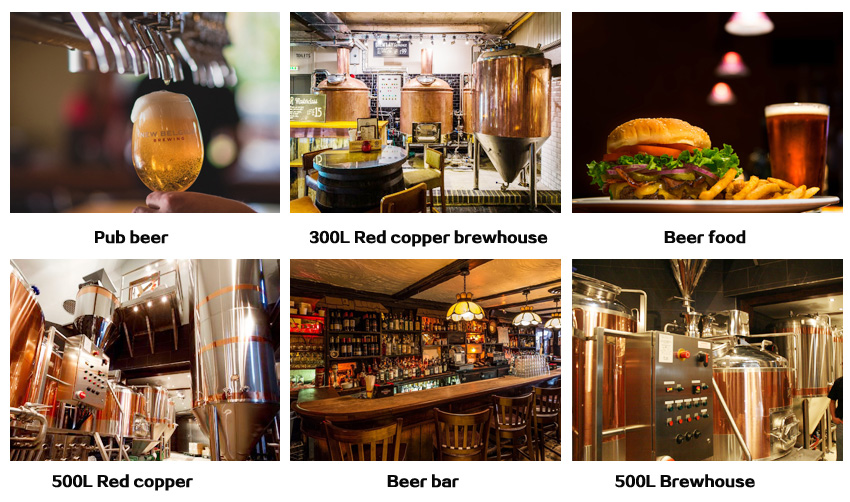

Where you can put brewery system

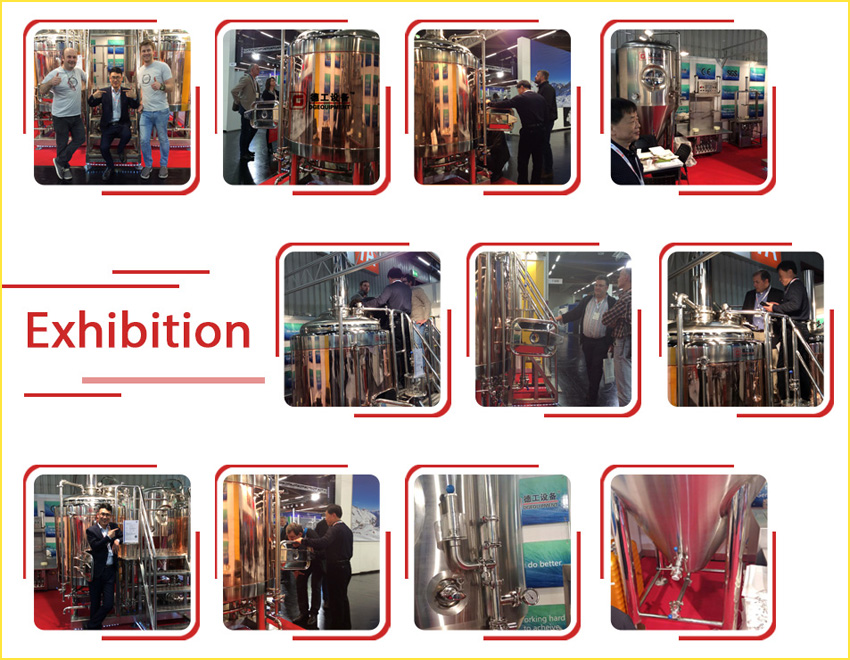

Exhibition in German

Certifications

In case you want to learn more info of our brewing system, I leave my contact ways here: