Description

2500L stainless steel customized conical fermentation tank

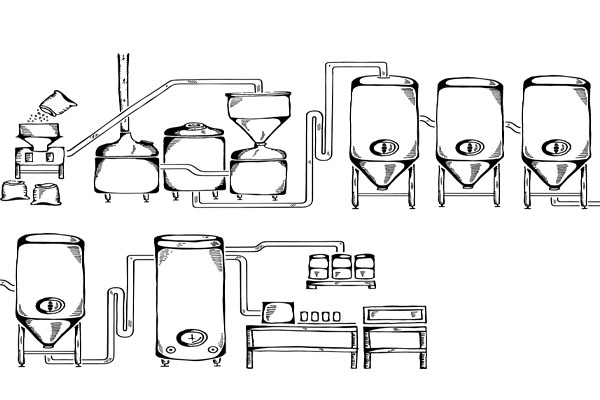

Beer brewing process:

Malt is ground in the grain mill.

The milled grains are transported with bags to mash kettle.

The grist is manually introduced through the access hatch.

In the mash tun the grist is mixed with brewing water from hot water tank(to form the mash)

In the lauter tun the dissolved liquid extract (wort) is separated from the solids (spent grains)

Brewing kettle is used for boiling (roughly 90 mins at 100 degree)

Whirlpooling is creating by circulating the wort.(the solids consist of protein and the hops roughage)

Once the wort stops rotating the cooling process is initiated.

The cold wort is pumped through a hose from the heat exchanger to the fermentation cellar via the brew house pump.

The wort ferments in the fermentation tank.

The green beer matures in the serving tank.

After the ageing process the beer can be served directly from this tank.

| | Technical parameter |

| Fermentation tank | Material:SUS 304

1.Inner thickness:3.0mm;outer thickness:2.0mm 2.Jacket thickness:1.5mm 3.Inner surface treatment:welds grinded to Ra 0.6um 4.Mirror surface finish inside. 5.Insulation: Polyurethane-thickness 100mm 6.cone 60 degree resist compression design,dripping 7.Heat exchange area: 5.1 m2 8.Vessel pressure:1.5 bar/3.0 bar |

| Yeast adding tank | Adopts sus 304 stainless steel fine polished process,outer stainless polishing.

Adding yeast sight glasses,aseptic air mouth,and wort pipe connection mouth. |

FAQ:

1.Can your brewing equipment make both lager and ale?

A: Yes, our beer brewing equipment can make both lager and ale.

2.How to achieve temperature control?

A: The PLC or digital displayer could control the temperature by connecting with the PT 100 sensor. The brewing tanks with rock wool to keep warm, the fermenters and bright beer tank with PU as cooling jacket to keep cool.

3.Is it possible to supply installation in our country?

A: Yes, we could supply our clients over sea service and direct the installation and brewing.

4.What type of control system?

A: Our control system is PLC control, also pass the CE.

5.What is kind of your packaging?

A: Export standard, wooden case, iron crate, or any suitable for long distance sea transportation.

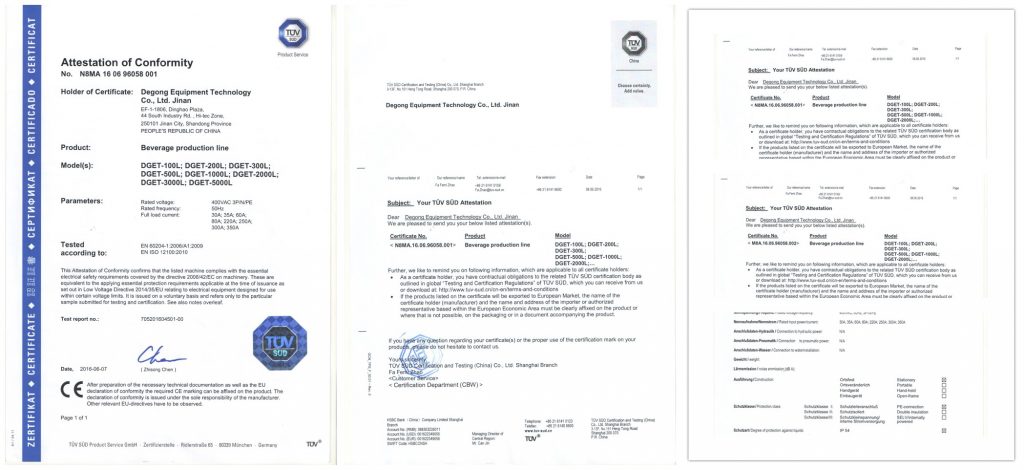

Certification:

Exhibition:

If you are interested in our beer equipment,please feel free contact me.