Description

The DEGONG “brewing system for sale” is made of high-quality food grade SUS304 with a high degree of polishing. The welds are polished to a sufficient degree.Heating control with overheat protection system and wort sticking. The heating shirt is thermally insulated with polyurethane foam and covered with an outer sheath of food grade stainless steel.

Beer brewhouse introduction

The brewhouse in the basic configuration consists of four units: the mash tank,lauter tank,wort kettle and whirlpool. The brewhouse can be combined to 2-vessels or 3 vessels or 4 vessels freely.

For 1000L brewing system for sale,3-vessels is a good choice.

3-vessels steam heating/gas heating/electric heating brewhouse

Mash tun&boiling kettle

The function of the mash tun is for sacharification, so that water-insoluble substances become water-soluble sugars, which can be fermented to obtain alcohol. This tank is a multifunctional tank, which can be used for mashing tank, boiling tank, whirlpool tank, as well as a hot water tank to provide hot water for cleaning the tank.

Equipping: ①Mash mixer with gearmotor ②steam removal pipe ③flow-through steam condenser

④Interior lighting ⑤Glass manway on top ⑥Light on top ⑦Temperature sensor ⑧Two rotary washing heads

⑨Thermal insulation (polyurethane foam) ⑩two rotating washing balls with connection to a CIP-station

Lauter tank

The function of the lauter tank is to filter out the spent grain to obtain clear wort. The lauter tank has a high-precision filter plate composed of several separate filter plates, which is convenient for disassembly, installation and cleaning. All of our lauter tank has a backwash pipe to prevent clogging of the filter plate.

Equipping: ①false bottom ②sparging pipe for mash washing ③gearmotor with grains raker ④glass manway

⑤lighting inside ⑥two rotary washing heads with connection to the CIP-station

⑦side hatch for unloading the grain ⑧Backflush pipe

Whirlpool tank

The function of thewhirlpool tank is to remove some of thermal coagulum produced after boiling. After whirlpool, the thermal solidification will be concentrated at the bottom of the cone. Open the drain valve to drain these impurities. Discharge clean wort from the wort outlet that is higher than the sewage outlet

Equipping: ①Interior lighting ②One rotary washing head ③Top glass manway ④Tangential port

Other Equipping:

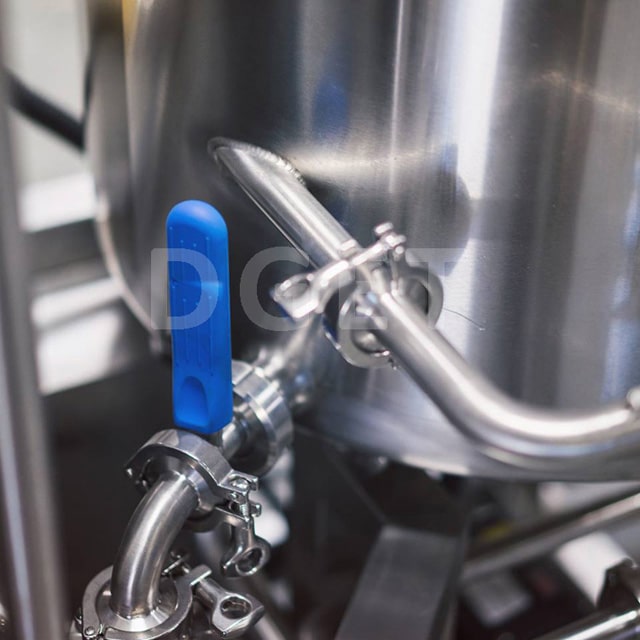

Pipeline butterfly valves;

Sight Glass;

Two pump for mash/wort/water

CIP-washing pipelines.

Brewhouse working platform with stairs

Except brewhouse, other systems of the complete brewing system for sale

|

Grinding System |

Malt mill; screw feeder, grain hoppers, grist hydrator |

|

1000L or 2000L Fermentation tanks and bright beer tank. Quantity is decided by you Accessories:Vacuum valve,hops adding port,CIP pipe,pressure gauge,mechanical regulation valve,sample valve,carbonation stone,temperature sensor,themometer,drain outlet. |

|

|

Refrigeration System |

Glycol water tank,circulate pump,chiller The cooling capacity is according to the quantity and capacity of fermentation tank and bright beer tank. |

|

CIP system |

Alkali tank,sterilization tank and pump |

|

Control System |

PLC control box |

|

Others |

Can also supply auto filling system, capping system, filtering system, water treatment system, pasteurizer and so on. |

304 SS or 316LSS or copper.

30% head space at least for each tank

Motorized mash mixers, lauter rakes and spent-grain plow

ABB Siemens motors/pumps on the whole system

Stainless steel process piping, work cabinet and control cabinet

Siemens/Schneider/Omron electric element

Grirst hydrator bowl with hot/cold liquor blending

Sight level indicators on fermenting system.

Insulated with a minimum of 100mm Chloride-Free PU Insulation.

Interior Finish: Overall polishing to 0.4 μm without dead corner

Adjustable Levelers provide a level tank regardless of floor slope;