Description

| Complete brewing equipment introduction |

Beer brewhouse of complete brewing equipment

We offers flexible beer brewhouse designs to ensure that optimal efficiency is achieved while including all requirements that a customer may have (such as spacing, tank distribution, etc.) Producing a high quality beer requires consistent brews and although experience plays a crucial role in the process, the limiting factor is the quality of the Brewhouse being used. Having a high quality Brewhouse will ensure that you have the necessary tools to keep the same flavor profile with every batch!

3-vessel beer brewhouse

Work Flow Process In 3-Vessels Brewhouse:Mash tank-lauter tnak-kettle/whirlpool tun:

Mashing is the process of combining a mix of milled grain and water and heating this mixture in a vessel called a “mash tun”. Second process, you need transfer the mixture of grain and wort into Lauter tun. You can get clear wort from this vessel. Thirdly, let’s pup the clear wort into a vessel named Kettle, in which will happen many key process including: wort boiling(usually 60 minutes), hops adding. At the end of the boil, the wort will be into whirlpooling, forcing the denser solids (coagulated proteins, vegetable matter from hops) into a cone in the center of the Kettle/Whirlpool tank.

3-Vessels 1000L Brewhouse Configuration:

|

3-Vessels Brewhouse |

Mash tun |

1000L (with 25% head space) |

Top mounted manhole |

|

Steam Jacket for optional |

|||

|

Lauter tun |

1000L |

Side mounted grain outdoor with grain chute |

|

|

Laser cutting V-wire False Bottom |

|||

|

Kettle/Whirlpool Tun |

1000L |

Steam heating |

|

|

Tangential whirlpool inlet |

|||

|

Hops filter |

30L |

Tri clamp aeration port with ball valve |

|

|

Heat exchanger |

25m2 |

Completely 304 SS Corrugated plates |

|

|

Wort Pump |

5m3/h, |

ABB, Sanitary SUS304, VFD control |

|

|

Pipe and fittings |

As design |

completely SS304, Work Platform is included |

|

|

Wort aeration device |

As design |

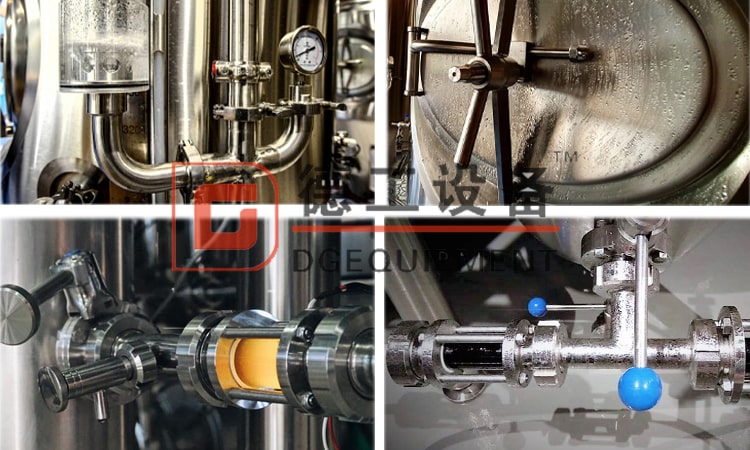

Features: 1. Stainless steel pipe assembly 2. Sight glass 3. 38 Sanitary tri-clamp connections Built in sight glass |

|

|

Wort grant |

50L |

stainless steel 304 |

Beer fermentation tank of complete brewing equipment

We offers a wide array of fermenters(fermentation) and brite tanks(maturation) tanks that are designed accordingly to our customers’ specifications and their needs. Our fermenter and brite tanks come in three different generalized builds (customizable tanks are also available): single wall, un-jacketed and jacketed. All of our tanks can be pressurized (unless otherwise requested) and the fermenters have an added bonus of functioning as both a fermenter and BBT tank.

Technical Characteristics:

|

Specifications: All AISI-304 Stainless Steel Construction Jacketed & Insulated Dual Zone Dimple Cooling Jacket Dish Top & 60° Conical Bottom 4 Stainless Steel Legs with Leveling Ports Working Capacity: 1000L Total capacity:1300L Inner Diameter: 1100 mm Outside Diameter: 1300 mm PU Insulation: 100mm Cylindrical Height: 1000 mm Total Height: 2550 mm Dimension: L x W x H 1300 x 1300 x 2550 mm Thickness: Inner: 3 mm, Dimple Jacket: 1.5 mm Cladding: 1.5 mm |

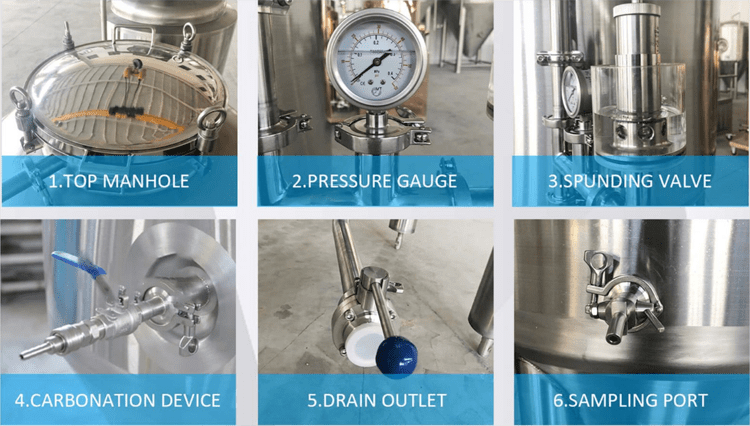

1000L Fermenter Includes: Top Manway or Side Shadow less Manway Racking Port with Tri-Clover Butterfly Valve Tri-Clover Outlets CIP Arm and Spray Ball Hops addling port Sample Valve Pressure Gauge Safety Valve(Apunding valve and pressure release valve) Thermowell with Tank Thermometer Carbonation stone valve Level gauge(Optional) All fittings, clamps, and valves are included with tank. |

| DEGONG company information |

Our beer brewing equipment include malt crushing system, saccharification system, fermentation system, glycol system, CIP cleaning system, controlling system, packaging system and all complete set of bar selling system. We could provide customization service, OEM service. Different type of equipment configuration combination could be made as per customer’s requirement.

If you have interest,please get in touch with me freely.