Description

Beer fermentation system contains beer fermentation tank and beer bright beer tank.Both of them are double wall stainless steel 304 isobaric tanks.Among,the fermentation tank can be used as bright beer tank.Of course, if you have your own refrigerating room, you can choose a single layer fermenter or bright beer tank, and control the temperature of the beer fermentation system directly by controlling the temperature of the room.

1000L Fermentation Tanks-Beer fermentation system

Fermentation is the next step in the brewing process after the wort has been prepared.

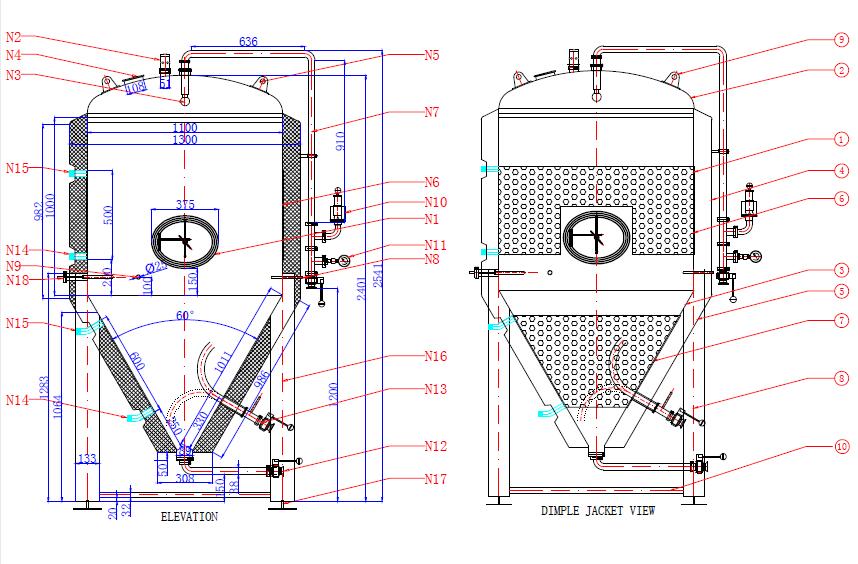

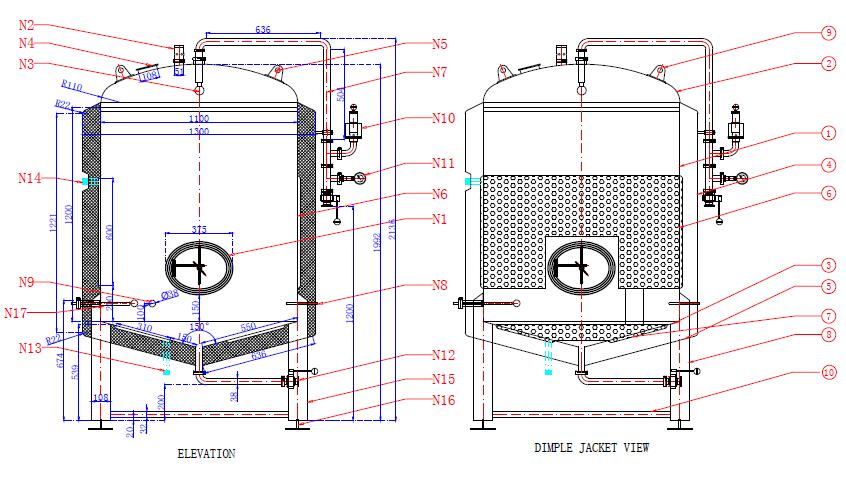

Fermentation tanks hold the wort while yeast converts to sugar in the wort into alcohol and carbon dioxide. These tanks should have a cone-shaped bottom, which facilities the process of recovering the yeast for later use.

1000L Brite Tanks-beer fermentation system

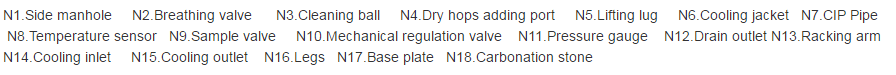

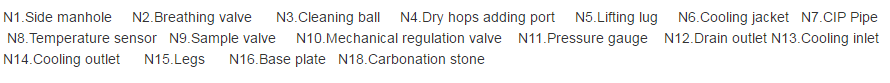

Beer is filtered and pumped into another tank known as a secondary fermentation or brite tank after the fermentation process is largely complete.

A brite tank allows the beer to further clarify and carbonate before being transferred into a bottle, can or keg for consumption. Some brewpubs also serve beer directly from a brite tank.

Technical parameter of beer fermentation system

- Inner Shell: 3mm, 304 Stainless Steel

- Outer Shell: 2mm,304 Stainless Steel

- Inner shell design pressure 29PSI(2bar), testing pressure 29PSI(2bar), designed to suit all types of craft breweries.

- Inner cooling jacket design pressure 29psi (2 bar).

- 25% headspace for fermenting process.

- Minimum 3 inch Thermal Polyurethane Insulation with both cone and shell coolant jackets.

- Chloride ion barrier paint on the out surface of the inner shell to prevent any potential corrosion to ensure longevity.

- Tank inner side is polished within 0.6µm sanitary finish.

- Tank outside is 2B stainless steel plate(optional brushed stainless, #4 finish).

- Shell and bottom cone cooling jacket for better temperature control.

- Pillow Plate on shell body and cone; Omega laser welded and inflated.

- Hook outside on the shell for ladders.

- Other customization possibly available upon request.

1000L Fermentation tank

Fermentation tank

Bright beer tank

If you have interest in DEGONG Fermentation tanks,welcome to contact me freely