Description

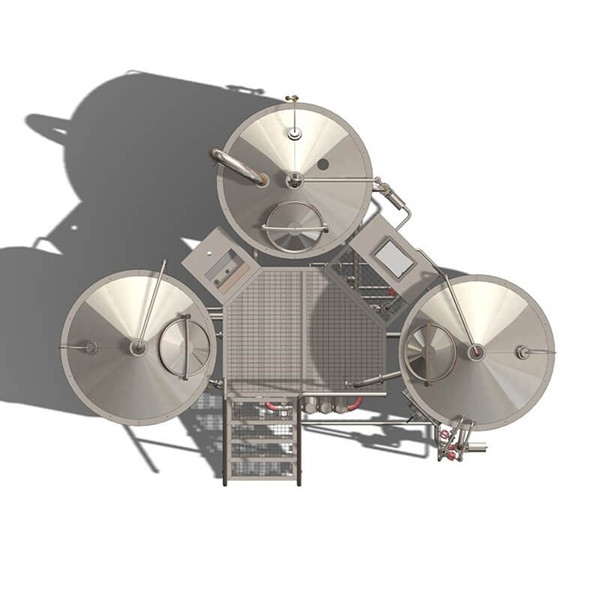

1000L 3-vessel stainless steel beer brewing equipment for sale

Features of brewhouse:

– Mash & Lauter tun: Brewing & sparging water blending port, VFD rake, with wort grant, mash hydrator, etc

– Kettle & Whirlpool: Dimpled steam jackets or direct burning heating, as well as electric immersion heating

– Hot water tank: Steam heating, direct burning or immersion electric heating.

– Heat exchanger: 2-step or 1 step, with fittings such as thermometers, venturi aeration unit, etc

– Cellars: Singe, double or multi-time brew size fermenters and BBT

– Cellar Control: Automatic Temp. control with solenoid valves

– Portable CIP cart: with an electric immersion Heating alkali tank and a sterilization tank, automatic Temp. control and a washing pump, etc

– Customized design of tanks, production flow, etc as per customers’ brewing process and beer features.

– Customized arrangement of brewhouses’ vessels, in rows, angle or square to fit the customers’ existing buildings.

– Dismountable basic frames with operators’ platform and pre-built piping for convenient site installation.

– Multi brews per 24 hours

Detail of beer brewing equipment

| Structure: | mash tun & lauter tun,kettle tun,whirlpool tun, hot liquor tank |

| Capacity: | 1000L |

| Dimension: | Φ1960x3400mm |

| Material: | Stainless steel 304 |

| Heating Way: | Steam heating/electric heating/direct fire heating |

| Electric Power: | 3 Phase,380V,50 HZ |

The brewhouse is used to get quality wort by mashing, lautering, boiling and whirlpooling etc. In the independent commercial or industrial beer plant, the brewhouse is usually customized to three even four vessel for getting a super output, 4-5 batches per day. Accordingly, the brewmasters would work in shifts to keep the brewhouse running at day and night. In order to save labor efficiently, the control system of brewhouse equipment usually be much more automatic, such as the pneumatic valve etc. It is in compliance with modern brewery standards and specifications. Besides, in some beer plant, the brewmasters would add secondary ingredient as adjunct starch source, like rice, corn etc. If so, a extra cooker had better be equipped in the brewhouse.

If you are interested in beer equipment, please feel free to contact me.