Description

The brewing required equipment is: Miller→mashing tank→lauter tank→boiling tank→whirlpool tank→hot water tank→wort chiller→aerobic device→yeast adding tank→fermentation tank→bright beer tank→chiller→glycol tank→CIP cleaning system-control system.

After beer brewing,we need to fill it into bottles,cans or kegs,so it will need bottling line,canning line or kegging machine.Some beer suppliers will sell commercial beer,so it will need to be filter and sterilized to improving their shelf life,then filter and pasteurization machine is necessary……And some breweries will sell beer in their bar or restaurant,so they will need beer dispenser.

That is to say,we can provide all kind of double layer beer brewing equipment according to your different requirements.

Features of DEGONG Double layer beer brewing equipment

The mashing tank-lauter tank-boiling tank-whirlpool tank can be combined freely,such as mash/lauter tank combined+boiling/whirlpool tank combined,or mash tank+lauter tank+boiling/whirlpool combined…..

Therein,mash/lauter tank combined+boiling/whirlpool tank combined is more popular.

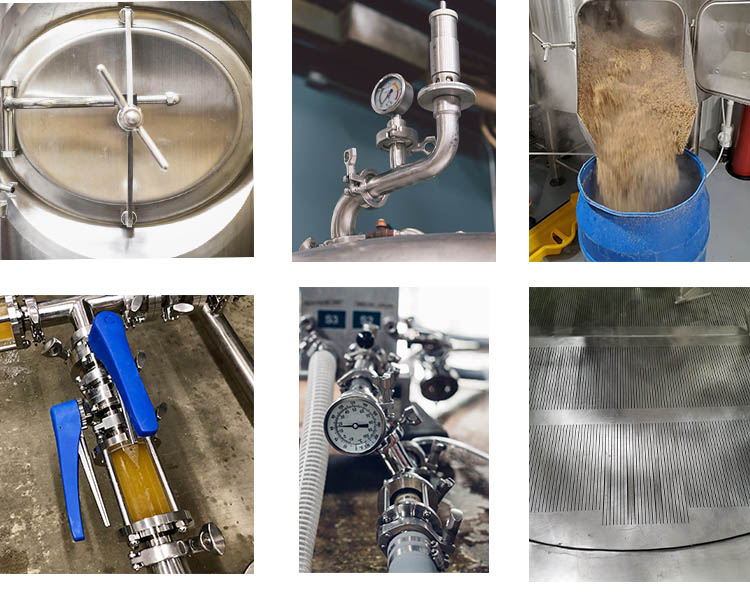

- mash/lauter tank with Siemens VFD motor for raker,easy installation false bottom,,high accuracy temperature sensor,sparage ring and cleaning ball

- Boiling/whirlpool tank with Siemens VFD motor for agitator,tangential port for whirlpool,with steam jacket or electric heating pipe,high accuracy temperature sensor,cleaning ball.

- Hot liquid tank(Optional) high accuracy temperature sensor,cleaning ball.

The heating method of mashing system can be electric heating,steam heating and direct fire heating.

The heating method of mashing system can be electric heating,steam heating and direct fire heating.

- Electric heating,it will need a electric heating pipe. Its advantage is that it can save cost. But for some other countries where electricity is very expensive, its using cost is expensive. Then they will choose direct fire heating and steam heating. The disadvantage of electric heating is that it is easy to occur paste pot.

- Steam heating, it is the most stable and efficient heating method. But it will need a steam boiler(gas boiler,diesel boiler and electric boiler)and will add some equipment cost.

- Direct fire heating method, for some countries where the electric is expensive and steam boiler using is very strict,this way is suitable.