Description

1000L Brewery Brewhouse of commercial brewing equipment

1000L 3-vessel steam heated steel beer brewhouse

Brewhouse is always deemed as the heart of a commercial brewing equipment. The function of brewhouse system is to convert the mixture of malt and water to wort which includes sugars, proteins,etc… with the help of different enzymes. A brewhouse system is generally heated by gas, steam or electric. However, steam heating method is the wildly accepted one because of its evenness.

Standard technical parameters of 1000L brewhouse system:

- Made of stainless steel or red copper

- Heating method: Gas, steam or electric for your choice

- 2,3,4 vessel which depends on your own requirements

- Thickness of inner shell: 3.0mm, Thickness of outer shell:2.0mm, Thickness of jacket: 1.5mm

- Design pressure of jacket: 3 Bar, Working pressure of the jacket: 1.5-2 bar

- Pressure inside the tank: Atmospheric

- Insulation: Polyurethane, Thickness: 100mm

- Grist hydrator is equipped

- Sanitary spraying ball of 360 degree coverage

- Condenser pipe

- Wort grant

- Speed variable wort pump with ABB motor

- Siemens/ABB motor for raker and blender

- With Wort aeration system

- Tempered glass manhole & LED flashlight

Pictures of 1000L brewhouse:

Mirror polish surface treatment for inner shell

350mm tempered glass top manhole

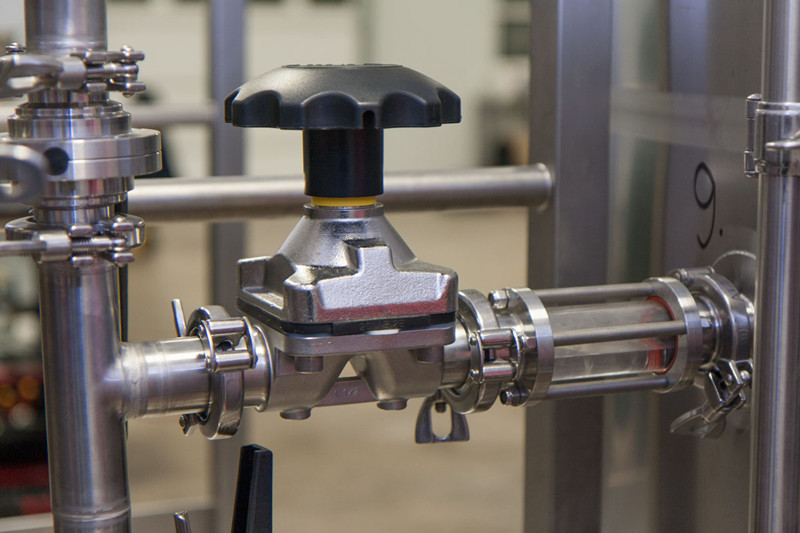

Through sight glass to see the clarity of wort

Discharge the spent grain from Lauter tun through the side manway

1000L fermentation system

Cylindrical fermentation tank & maturation tank

Fermentation system is to convert the wort to drinkable beer through two stages which are separately aerobic respiration and anaerobic respiration. Fermentation tank is generally cylindrical-conical shaped to harvest the yeast easily. During the first stage, the yeast can reproduce rapidly by consuming the oxygen. Once the oxygen inside the wort is used up, the second stage starts, during which the numerous yeast will generate the Co2 and alcohol. The fermentation period of different types of beer is different, but it is generally about 14-18 days.

Standard technical parameters of the fermentation tank:

- Made of food grade stainless steel 304

- 100% TIG welded

- Thickness of inner shell: 3.0mm, thickness of outer shell: 2.0mm, thickness of jacket: 1.5mm

- Control method: temperature control

- Insulation: polyurethane, thickness: 100mm

- Design pressure inside the tank: 3 bar, working pressure inside the tank: 1.5-2 bar

- Surface treatment: Mirror polish

Accessories:

- Pressure relief valve

- Dry hopping hole

- Top manhole (Or side manhole which depends on the capacity of the tank)

- Sanitary spraying ball of 360 coverage

- Thermometer

- Pressure gauge

- Pressure bunging device

- Temperature sensor

- Sample valve

- Racking arm

- 4 pcs of heavy duty leveling legs

- Exterior level meter

Pictures of 1000L fermentation tank:

Side manhole for cleaning and maintaining easily

4 pcs of heavy duty leveling legs

Certificate:

Our equipment are TUV, CE, ISO certified. Our company is the only one who has obtained the TUV certificate among all suppliers in Northern China.

Company introduction:

DEGONG is a large manufacturer of beer brewery equipment, which the headquarter is located in Jinan. Dedicated to beer brewery equipment, beer fermentation tank, beer bottling machine, beer keg filling machine, beer filter machine, wine production equipment, wine fermentation tank, pasteurizing device and so on…

We research and develop beer brewery system and beer bottling machine independently from 2012, and we have developed overseas market successfully. Now we have established sales services network of more than 10 core agents, more than 100 distributors and project contractor. We have finished thousands of project across the world.

Contact us:

Email: [email protected]

WhatsApp: +86 15863177821

Tel: +86 15863177821

Contact person: Zhe