Description

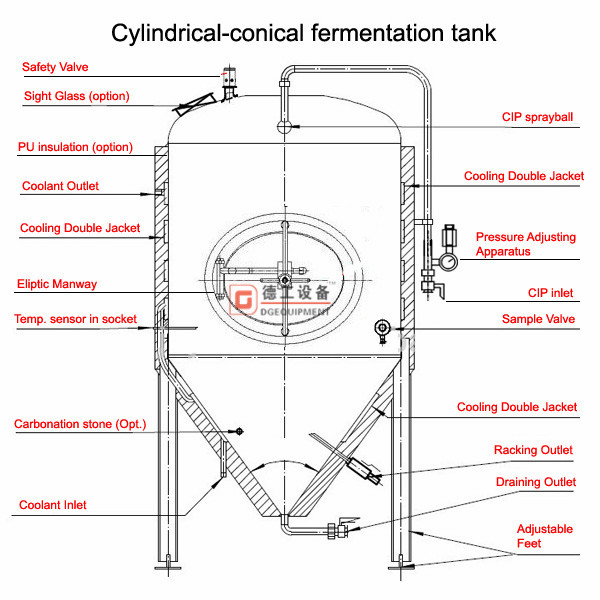

1000L/batch Fermenting vessel

Medium Beer Fermentation Tank

All parts of beer fermentation tanks are made in premium grade certified stainless steel materials (2B or precise polish for available surface).We are always attaching high importance to be in line with international standard and fortunately, DEGONG has taken up main markets in the Europe,Africa and America. We also can custom fabricate any tank to meet your brewery’s space and height restrictions.

Conical beer fermenting vessel(top or side manhole)

The fermentation tank size can make according to clients needs.

Our tanks use dimple jacket for better cooling effect.

The manhole location can be put in the top or side, consider the cooling effect, choose which one based on your requirements. If use side manhole, our manhole is shadow less manhole, better for clean, have no dead cone.

| 1000L beer fermenting vessl | |

| Net Volume | 1000 L |

| Total Volume | 1300 L |

| Dimensions: | Ø 1300 x 2500 mm |

| Bottom Angle of the Tapered Part: | 60° Conical |

| Design pressure | 0.3Mpa |

| Working Pressure | 0.15-0.2Mpa |

| Dish Head | Domed |

| Legs | Adjustable, 4 pieces |

| Cooling jackets | Independent, in the cylindrical and conical part |

| Cooling area | 2.68 m |

| CIP Arm | DN 32/40 with DN 32/40 valve, 1 pc |

| Drain Outlet | DN 32/40 with DN 32/40 valve, 1 pc |

| Beer Inlet and Outlet | DN 32/40 with DN 32/40 valve, 1 pc |

| Spray Ball | Screw connected, 1 pc |

| Manway door | 350/400/500 |

| Safety Valve | At the upper bottom |

| Sample valve | |

| Electronic Temperature Sensor | PT 100, 1 pc |

| Bimetal Temperature gauge | DN 25 1 pc |

Fermenting vessel parts

Breather valve with Pressure gauge;side manway;drain outlet

Specification of fermentation tanks/unitanks:

4 stainless steel legs with leveling footpads

Interior shell: 304 stainless steel, thickness 3mm

Exterior shell: 304 stainless steel, thickness 2mm

Interior and exterior finish bright polish to 0.4~0.6 μm, hygiene surface

All Interior welds ground to a smooth 0.4~0.6 μm sanitary finish

Flanged and dished head top and bottom

Over 20% headspace unless a different volume is requested

Combined drain extensions and beer port are standard

Top manway or side manway door

Dual zone in sidewall and bottom dimple cooling jacket with glycol inlet and outlet

Polyurethane insulation thickness 80mm for cooling jacket on side and bottom

Welding CIP arm and rotating 360 degree reach spray ball

Carbonation system with micron stone

Solenoid valve, pressure relief valve (safe valve) are standard.

Pressure gauge

Temperature sensor well

All clamps and gaskets to attach all accessories

Tank complete with piping, fittings, sanitary valves and all parts.

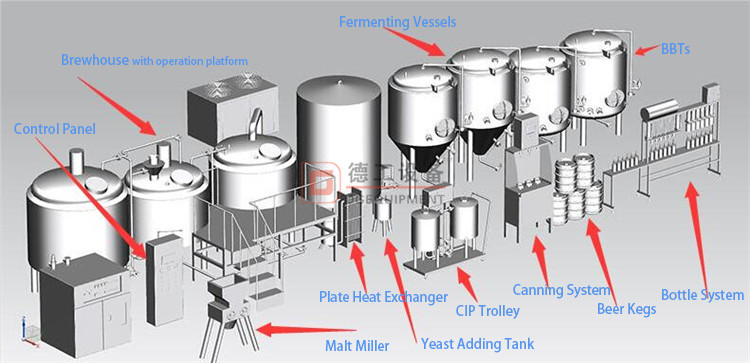

We can arrange the tanks reasonably according to your plant. After you purchase, we have a dedicated engineer to install it for you, if you need. Currently we have many projects in operation, you can contact or check the quality of our system.Contact us

Ready to Get Started Building Your Dream brewery?

Contact DEGONG Alice Today!