Description

DEGONG 1000L brewery tank can be designed according to different brewing requirements of customers.Such as if you brew high-concentration/gravity beer, we will design lauter tank with a wide diameter to increase filtration efficiency; If you brew 2-3 batches every day,we recommend you 3 vessels brewhouse with mash/boiling tank+lauter tank+whirlpool tank; If you just need to brew 1 batch everyday,we recommend you 2 vessels brewhouse with mash/lauter tank+boiling/whirlpool tank……

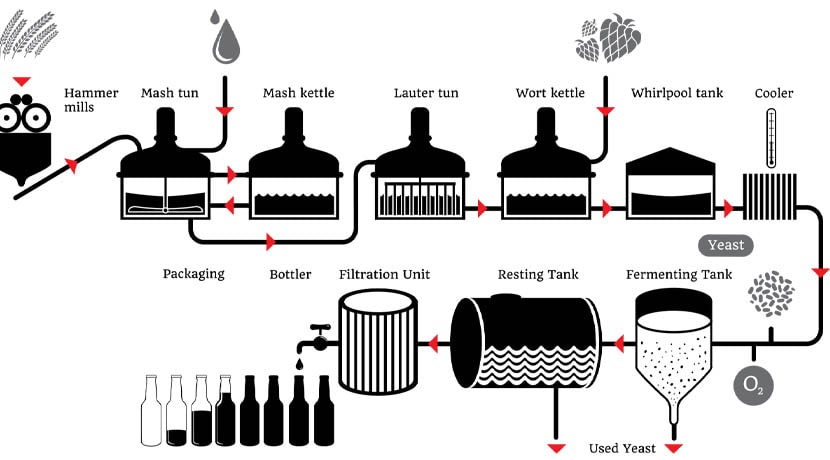

Component of the complete 1000L brewery tank

Grain mill system(grain miller, flex auger, grist case)

1000L 3-vessels beer brewhouse

Mash tank/Boiling tank – grist hydrator, agitator, frequency drive, bottom and side with steam jacket

Lauter tun – false bottom, rake system, sparging, rake speed adjustable

Whirlpool tun-tangent inlet

Pumps with ABB motor

Stainless steel 304 working platform

Plate heat exchanger – 304 or 316 plates

1000L/2000L Fermentation tanks/Brite beer tanks

2000L HLT and CLT

Glycol cooling system(glycol chiller, glycol tank)

CIP system

PLC Siemens control system, CE/UL Rated controls and electric components

Sales equipment,such as keg washer/filler,bottling line,canning line,draft beer machine,dispensor

More details of the 1000L brewery tank

- Volume: Working volume and 20%-30%additional space.

- The normal pressure is 0.2Mpa, maximum test pressure is 0.4Mpa.

- Beer brewhouse: Four functions(mash,lauter,boiling,whirlpool) can be combined in 2 or 3 or four tanks.

- Heating method can be electric heating,steam heating and direct fire heating.

- Material:Interior SUS304 2.5~3.0mm, exterior stainless steel/luxury red copper cladding 1.5~2.0mm

- All of welding seam required polishing, which is more smooth tank surface.

- Insulation layer: Polyurethane or rockwool, thickness 80~100mm.

- We use plasma torch to cut the materials on the soft carpet, avoid to damaging the surface of stainless steel, and then we adopt double argon protection welding.

- All electric component is famous brand,such as Siemens,Omron,Schneider,Danfoss.

- The pump and aigitator motor is controlled by VFD

Service

Certification

Company info

Contact us