Description

Brewhouse of beer brewing equipment assembly adopted with three vessels: Mash/Kettle tank, Lauter tank and Whirpool tank.Steam heating method is better for its stablity and effciency.All of the tank will have separate steam jacket in order to improve tanks’s using efficiency and adopted with working platform for operating.

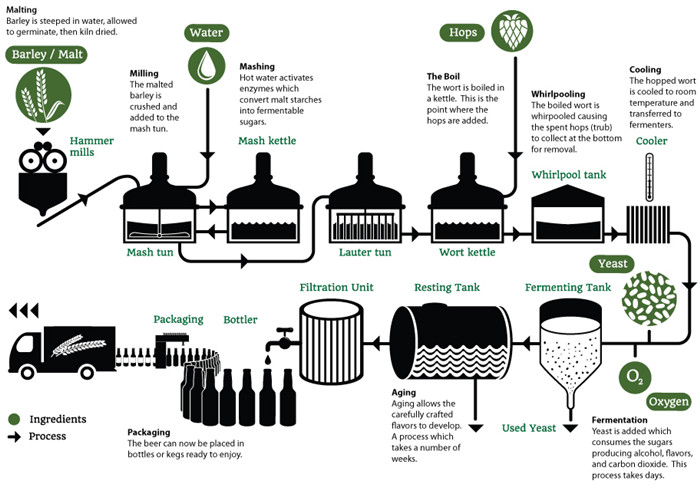

Beer brewing process

1.Malt is ground in the grain mill

2.In the mash tank, the grist is mixed with brewing water from hot water tank to form the mash

3.In the lauter tank,the dissolved liquid extract (wort) is separated from solids(spent grais)

4.Brew kettle is used for wort boiling(roughly 90 min hours at 100℃)

5.Whirlpool is created by circulating the wort.

Once the wort stops rotating the cooling process is initated.

6.The wort ferments in the fermentation tank(primary fermentation)

7.The green beer matures in the serving tank.

8.After the ageing process the beer can be served directly from this tank.

Technical Parameter of SUS304 Brewhouse

Material:Inner(SUS304),thickness:3.0mm,Jacket(SUS)304,thickness:3.0mm

Cylinder(sharp type,SUS304),thickness:3.0mm

Inner surface treatment:welds grinded to 0.6μm。

Insulation:Polyurethane-thickness 100mm

Temperature way:Double matal thermometer

Outsourcing surface:Weld polishing processing

Jacket Pressure:design pressure 0.3MPa,working pressure <0.2MPa.

CIP 360 degrees Omni bearing cleaning

Accessories

Why choose us

1. Our advantage

Own factory, Fine workmanship, Durable equipment, Beautiful appearance, Price concessions, Simple operation

2. Our certificate

Our equipment is coming with certifications of PED and our company is TUV approved. We use CE approved components for customers. The quality, specification and function all meet the treaty of contract.

3. Our service

We can provide engineers to help you install the equipment, and we can also provide winemakers to help you solve technical problems。

Packing & Delivery

Standard packing:

1.Cord ,film membrane

2.Firm membrane, wood box for free fumigation

Transport: by sea

Delivery :

1.We put your order into our tight production schedule to ensure the punctual delivery time.

2.Production or inspection report before your order packed.

Contact us

If you have needs for craft brewing equipment, please feel free to contact us,my pleasure.