Description

The set of 1000L brewhouse includes mash/lauter tank, kettle/whirlpool tank and a hot water tank that’s double of capacity of mash tank. A small steel open tank as buffer tank. Brewhouse is always deemed as the heart of a brewery line, from the milled malt feed-in to plate heating exchanger, each process should be controlled precisely to ensure the wort is good enough for the next step – fermentation.

Standard configuration of beer brewhouse system

Mash/Lauter tun

– stainless steel grist hydrator w/ hot & cold hydration inlet

– Upper and lower jackets(hot water or steam)

– Heavy duty false bottom with pillar support system

– CIP spray nozzles under false bottom

– Multiple wort drain locations

– Fully insulated vessel

– Food grade sanitary stainless steel

– SS CIP high-low rotary spray ball with 360 degree of coverage

– Interior light

– Sparge ring assembly

– Top manhole (tempered glass)

– Side manway for automatic spent grain out process

– Automatic variable speed rake system and spent grain plow

Kettle/Whirlpool tank

– Upper and lower steam jackets

– Tangential whirlpool inlet

– Fully insulated vessel

– Stainless steel

– SS CIP high-low rotary spray ball with 360 of coverage

– Top manhole (Tempered glass)

– Interior light

Wort pump

– ABB food grade stainless steel wash-down pump

– VFD speed control

Whirlpool pump

– ABB food grade stainless steel wash-down pump

– VFD speed control

Wort grant

– Stainless steel cylinder

– Total wort volume approx 11 gallons

– Sight level glass

– Isolation valve

– Drain valve

– All sanitary tri-clamp connection

Wort aeration assembly

– Stainless steel pipe assembly

– Aeration stone

– Built in sight glass

– Sanitary tri-clamp connections

Standard configuration of fermentation tank

Fermentation tank

– Stainless steel 304 sanitary construction

– 100% TIG welded and sanitary polished

– Design pressure: 1.5-2 bar, test pressure: 3bar

– 4 heavy duty stainless steel legs with adjustable height and leveling footpads

– Interior shell: 304 stainless steel , thickness is 3 mm

– Interior is 2B and exterior finish bright polish, sanitary surface

– Tri-clamp sanitary fitting

– Vacuum & pressure relief valve

– Pressure gauge

– Thermometer gauge

– Sample valve

– Lifting lugs

– Ladder hooks, also designed to hold brewers hose when not is use

– Side manhole

– CIP arm and rotary spray ball 360 degree of coverage

– Dual zone cooling jacket with glycol inlet and outlet

– Rotation racking arm

– Dry hopping hole

– Thermo-well (Temperature sensor is also included)

Certificate

CE ISO TUC certificates

Customer show

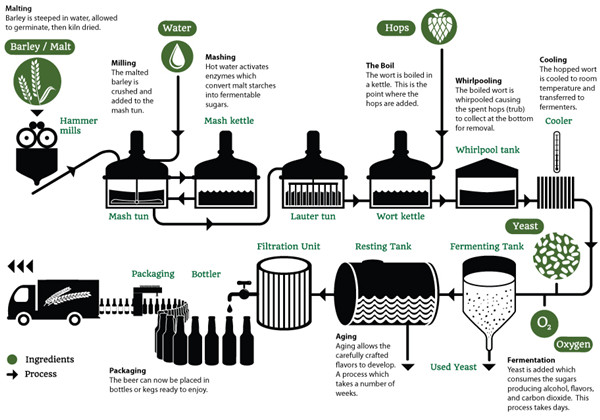

Brewing process

Our services

– Free consultation service before, during, after sales; Layout in 3D or CAD drawings of your brewery

– Professional engineers going abroad for the installation, debugging, and training, all the travelling cost and locate food and hotel shall be affroded by the buyer

– The installation period is about 15 days including assembling brewing tanks and training the operators. It is free of charge within 15 days. The buyer will be charged USD50 per day for for each engineer for the extended period

– Round the clock assistance via Phone, Email, Skype, WhatsApp, MSN, or any other communication methods available to the customer

– Assist to purchase facilities by seller including bottling system, steam boiler, water treatment, etc should be installed separately. If needed, cost calculated additionally

– Brewing technology, brewing recipe, can be offered

– More spare parts are available to offered freely