Description

What is beer conical fermenters

Conical fermenters, or more commonly fermentation tank, are key components in beer brewing.Fermentation tanks are specialized tanks designed to precisely control temperature and maintain the optimal conditions for fermentation, which occurs once the wort has been transferred from the brewhouse to the fermenter; a conical-bottom design is highly recommended for fermenters allowing for easier yeast harvesting.

size:

Gross capacity:1500L

Useful capacity:10bbL

Outer :Ø1300mm;

Inner:Ø1100m

Height: 2750 mm;

Technical parameter:

a.Stainless steel 304 sanitary construction

b.100% TIG welded and sanitary polished

c.Design pressure is 0.3MPa,using pressure is 0.15MPa

d.4heavy duty stainless steel legs with adjustable height and leveling footpads

e.Interior:thickness 3mm; Outerior:thickness 2mm

f.Interior treatment:Mirror polishing

g.Mirror polishing to 0.4μm without dead corner.

h.Jacket:stainless steel 304,thickess 1.5mm

i.Insulation:100mm Polyurethane

j.60 degree conical bottom

k.Heat exchanger area:3.1m2

Details configuration accessories:

l.Side mahole

m.Lifting ear

n.Temperature sensor

o.Pressure guage

p.Machinery regulator

q.Breathing valve

r.Hops adding hole

s.Simple valve

t.Raking arm

u.Valves&fittings

v.Add carbonation stone

w.blow-off/ clean-in-place (CIP) tube

Functions of items of conical fermenter’s body

1.Cleaning temperature: Cleaning the beer brewery fermentation tanks with hot water or steam sterilization is very dangerous, and it is easy to form a vacuum pumping phenomenon. Therefore, the temperature of the cleaned fermenter should not exceed 40 degrees.

2.Mechanical regulating valve:Mechanical regulating valve, when the pressure in the fermenter rises, danger will occur, so must install the valve.

3.Breathing valve:Large tank is very sensitive to v acuum, and a small negative pressure will cause it to deform.

4.Temperature sensor:the tank requires accurate temperature control and precise temperature regulation. So we should install it.

5.Pressure gauge:In the process of fermentation or storage, we should monitor the pressure. The pressure gauge shows the pressure with a pressure gauge.

6.Sampling valve:A sampling port is set on the fermenter to check the fermentation condition of of beer.

7.Manhole:It is convenient for people to go in and clean. Check the tank for cracks or corrosion. Check the dead corners on the tank or in the pipeline.

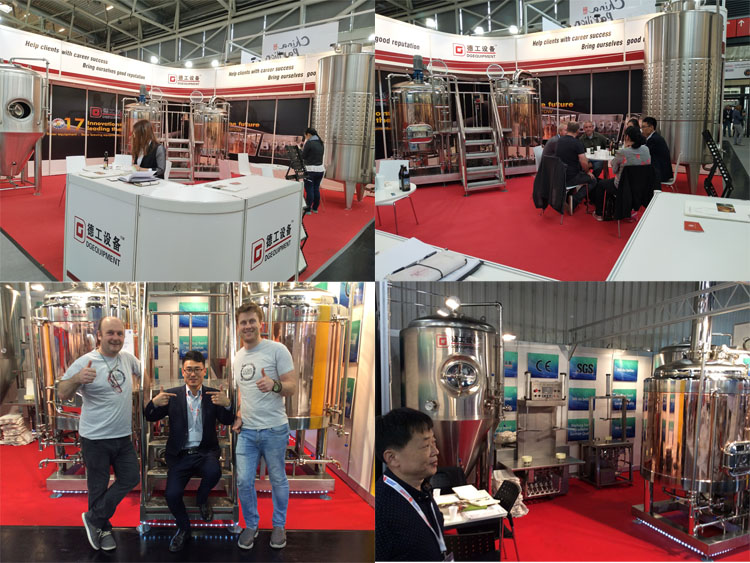

Company strength

1.Industry-leading 3 year warranty on all fabricated vessels for long-term hassle-free operation.

2.Tanks are tested prior to shipment to avoid on-site repairs, guarantee uninterrupted startup and assured vessel performance.

3.All sanitary piping designed for quick breakdown and minimum reassembly time.

4.All tank fabrication procedures follow a strict quality control program.

5.Control panels are UL Approved and NEMA 4 for “wet” environment use.

6.Designed by brewers and engineers providing a simple design that’s easy to use, safe and highly efficient.

7.Accord with TUV&ISO&CE certification

If you have interest,please feel free to contact me.

If you have interest,please get in touch wiht me freely.