Description

Beer brewing progress flow

![]()

1000L custom 2/3/4 vessels insulated industrial beer brewery equipment is a normal configuration that most customer will choose.Steam heated or gas heated or electric heated;2 vessels or 3 vessels or 4 vessels;And most customer also will choose a hot water tank to improve mashing efficiency.And the whole progress will be controlled by a control panel.

Other configuration of 1000L industrial beer brewery equipment:

| Other construction except 3-vessels | 1.2-vessels brewhouse:mash/lauter tank and boiling/whirlpool tank

2.3-vessels brewhouse:mash/lauter tank,boiling tank and whirlpool tank mash/boiling tank,lauter tank and whirlpool tank 3.4-vessels brewhouse:mash tank,lauter tank,boiling tank and whirlpool tank Hot water tank and cold water tank is for optional |

| Heating method except steam heating | 1.Electric heating

2.Direct fire heating |

| Steam boiler (If choose steam heating) | Electric boiler

Gas boiler Diesel boiler |

| Specifications |

Inner:SS304.TH=3.0mm Outer:SS304.TH=2.0mm Double-layer wall structure with the insulation of 100mm Polyurethane Steam jacket or heating element 100% TIG welding with pure argon gas shield Interior Finish: Overall polishing to 0.4~0.6 μm without dead corner Heavy duty false bottom with 0.7mm gap of the sieve Fully insulated vessel SS CIP High-flow rotary spray ball with 360 degree of coverage Sparge arm assembly Top manway Side manway for spent grain out Sight glass light Grist hydrator Raker with VFD motor in Lauter tank Agitator with VFD motor in boiling tank |

![]()

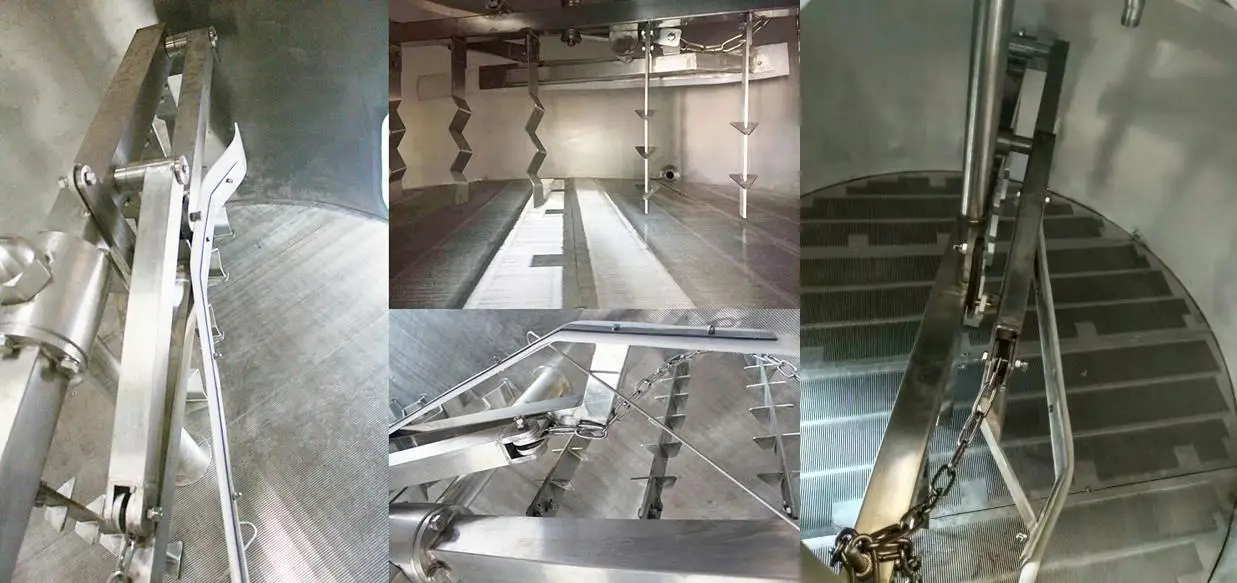

Details pictures

- Sieve plate: The sieve plate is 20 mm above the bottom of tank. Regardless of any type of sieve plate, the opening ratio is generally 10% to 12%, and the opening width is 0.5 mm to 0.7 mm.

- Raker: Raker plays an important role in speeding up the filtration speed of wort and improving the quality of wort. In most cases, the first wort is filtered and the spent grain are squeezed together. At this point, the filtration speed is slower. Then rotate the filler to loosen the spent grains and increase the filtration speed.

- Agitator:The requirement of the agitator is:let solid particles can be suspended and evenly distributed in the liquid to avoid local overheating, causing anxious burnt and affecting the taste of the wort and the beer. The agitator adopts frequency conversion adjustment, and the speed can be flexibly adjusted according to the requirements of the mashing process

- Sight glass:You can check if the wort is clean through the sight glass.

![]()

1.Service

Before make order:We will provide most professional suggestions according to your specific condition.

After delivery:Our engineer will go to install equipment and teach how to brew beer

2.Packing & delivery

Wooden packing & iron frame packing. All of the innder will streatched membrane.

3.Exhibition

4.Production

5.Certification

Why choose us

1.24 months warranty,all life service

2.we dispatch our engineer to install freely.

3. Spare parts will be sent out in 24hours after payment finished.

4. The spare parts are free offered in the warranty period of machine.

If you have interest in our equipment,contact me freely.