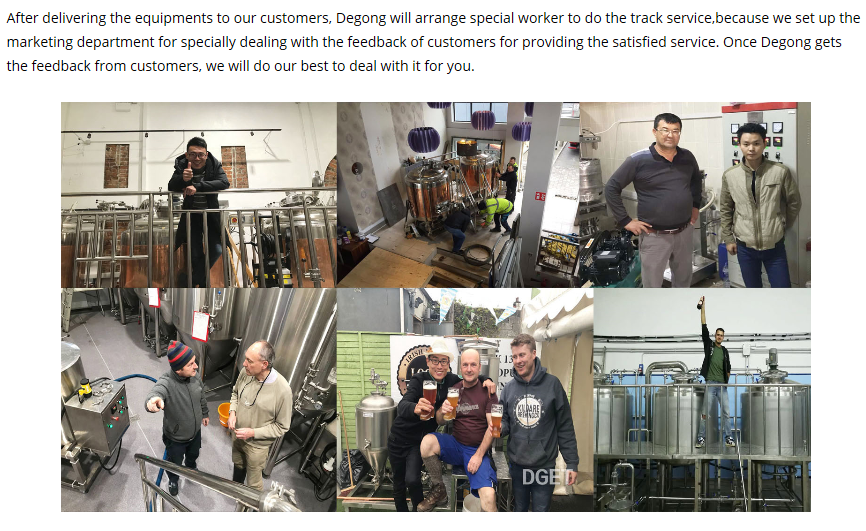

Description

1000L Micro Brewery can be a good start of your own brewery business.The brewhouse comprising of 2 or 3 or 4 vessels is mounted on a stainless steel skid or on the floor with piping, pumps, platform, etc, which are pre-built for convenient installation on site.

By learning each brewer’s individual needs, we will work with you on first stage layout design, on just right lautertun size, on piping design, on planning your expansion project in very first start to make your own microbrewhouse.

3-vessel Brewhouse of 1000L micro brewery equipment

The traditional 3-vessel brewhouse configuration is mash tun + lauter tun + kettle / whirlpool, or mash / boiling tank + lauter tun + whirlpool tank. Material is SUS 304 or 316 or copper

Brewhouse is designed and fabricated as the exact brewing process request from client and the local requirement. Tanks size designed based on beer’s type,such as gravity beer requires the lauter tank’s diameter is big enough, to promote filter speed. The goal is helping client with easy brewing operation, making the whole brewhouse setup more suitable for right recipe , increasing the efficiency and lowering the energy cost etc.

Basic configuration of 1000L micro brewery brewhouse

● Mash tun with stir, bottom & steam jacket, separate control

● Lauter tun with blade, counter washing and wort collect coil

● Kettle / whirlpool combined, with side and steam jacket, separate steam control for different batch size.

● Platfrom: All in line or tri angle

● All pump & Stir with VFD

● With hot water tank configured for sparging and mashing in etc.

● Valves to be manual butterfly one or pneumatic

● Piping connection to be TC or Thread.

● Support fittings: double / single stage plate cooler, grist hydrator, wort grant,hops filter,aeration device etc

Features of DEGONG brewing system

● Higher wort wort extract

● Lower energy cost and material consumption

● Well adjusted temp and water blending unit for better grain and water mixing

● Higher efficiency steam jacket to increase heating efficiency and lower energy consumption

● Special tank and piping construction to avoid the wort aeration problem and decrease the material lost

● Special designed steam condensing unit, with both steam condensing and water heating function

● Brewhouse automation with possible upgrading.

If you have interest in DEGONG brewing equipment,welcome to contact me freely.