Description

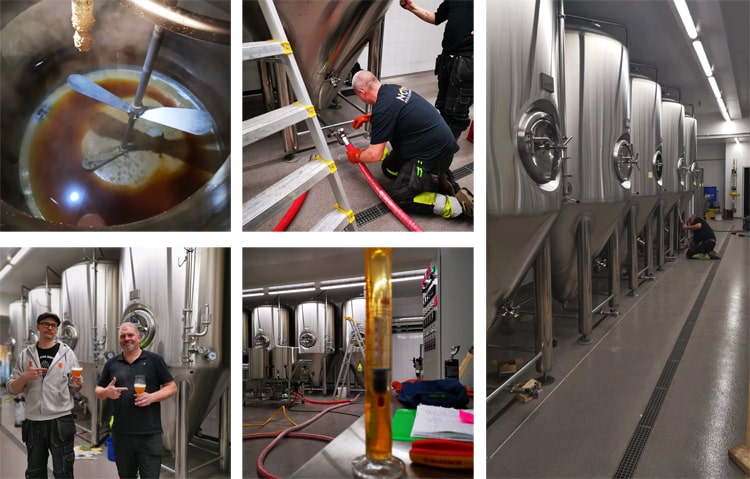

The 1000L brewing equipment is a popular model for customer.It is not too big and not too small, it can be used for both commercial brewery and private brewery. In addition,1000l brewing equipment’s production range is wide and the output is according to the number of fermentation tanks.The complete brewing system includes miller, mashing system, fermentation system,cooling system, control system and CIP system. Each system can be customized according to customer’s needs, such as 2 brewhouse or 3 brewhouse, steam heating or electric heating, etc. . . . .

Brewhouses/beer mashing system has several key pieces of brewing equipment. The whole brewery mashing plant has four function,which is mash,lauter,boiling,whirlpool. In the operation of the brewmaster.convert grain that has been milled through a specialty grain mill, into sweet liquid (we usually call it wort )”. Wort is subsequently fermented and finished in specialized beer tanks called fermenters and brite tanks.

Configuration of brewery mashing plant:

Mash &Lautertun: Brewing &sparging water blending port, VFD rake, with wort grant, mash hydrator, etc

Kettle & Whirlpool: Dimpled steam jackets or direct burning heating, as well as electric immersion heating

Hot Liquor Tank: Steam heating, direct burning or immersion electric heating.

Pumps: Lautering pump and whirlpooling/castout pump of VFD, HL pump

Piping: Tri-Clamp or DIN standard pre-built

Heat exchanger: 2-step or 1 step, with fittings such as thermometers, venturi aeration unit, etc

Brewhouse control: VFD, switches etc, Automatic Temp. control, etc

Specifications of 1000L brewery mashing plant

SUS 304/SUS316/Copper clad,Inner Thickness=0.3mm,Outer thickness=0.2mm

Optional heating style of steam, electric and direct fire for brewhouse tanks

PLC control panel with Siemens,Omron,Schenider element,and accord with EU standard

VFD controlled reducer and wort pump

Grist hydrator with strike water mixing station

Plate heat exchanger for cooling wort

Grant /hop guns for filter or storage first wort

Independent hot liquor tank or combine with brewhouse tanks

Independent cold liquor tank

Top glass manhole for checking mashing condition

Sight glass to check if the wort is clean

Wort oxygen system

2D/3D engineering for brewery set up simulation

Engineer install equipment and teach how to brew

Contact us