Description

Beer Fermenter Brewery Tank is a vertical, tapered, cylindrical vessel for the beer fermentation and maturation processes.Fermentation tank ,also refer to Uni-tank,which are vessels of various size usually made from stainless steel that contain a mixture of malted grain, hops, yeast and water to create a liquid collectively known in the brewing process as wort.Fermenter vary in temperature depending upon the beer being produced.

Beer Fermenter Brewery Tank features![]()

Tank body

Tanks are available with torispherical and conical bottom

Torispherical lid resists high pressure and design according to DIN Standard

Conical bottom assures the easier removal of yeast from the tank

Tanks are available with side, top and bottom manholes depending on the size and your needs

Top manholes can handle high pressure, easily to handle and made in insulated version

Side manholes are can be easily cleaned without any blind area

Material quality of the whole tank is food grade SUS304/SUS316/AISI304/AISI316

Etched and passivated inner surface with a roughness less than 0.4 µm to avoid the contamination spots that are hard to wash

Cooling

2-3-4 cooling zone on cylinder and cone depending on the size

Cooling jackets made with the spot welding technology

100 mm PU foam insulation with a thermal conductivity of 24 mW/mK for the safest storage of heat and economical energy use

100 % stainless steel coating available in a variety of surface finishes such as 2B pickled, different surface roughnesses, polished and marbled

Fittings

All pipes and fittings are made in accordance with DIN Standard

Material quality of all fittings are food grade SUS304/SUS316/AISI304/AISI316

Vacuum and pressure safety valves, complying with all standards and positioned for an easy cleaning

Stainless steel pressure gauge, optionally can be ordered in flat membrane version

Technological pipings on the tank (beer pipe, yeast pipe, CIP pipe) produced with using the bending technology where no welding is used resulting that there are no infection points that might occur at welding jointst

Depending on tank sizes, each tank equipped with 1-2-3 pcs of accurate thermal sensor

Technical parameter of beer fermenter brewery tank

|

Dimensions |

We can provide normal dimension if customer dont have special requirement.If have,we will Design suitable dimension according to customer’s requirement. |

|

Capacity |

Nominal capacity plus 25% |

|

Top Head |

Dished head |

|

Lifting Lugs |

2 lifting lugs |

|

CIP |

Removable CIP & fixed spray ball (180° up, 65mm) on 1½” TC with 1½” TC line down to working height |

|

Wall |

Inner thickness 3mm;Outer thickness 2mm. |

|

Bottom Cone |

60° cone angle, ”1½ knuckle radius to cone |

|

Cooling Jacket |

On sidewall and bottom cone – number of zones determined by tank size Maximum 0.3MPA working pressure, 1” to 1½” FNPT inlet / outlet |

|

Legs |

4pcs completely SUS304 heavy duty legs with leveling pad and legs support |

|

Insulation |

100mm polyurathane |

|

Manway |

Top manway or side manway |

|

Drain |

1½” TC butterfly valve c/w “J” pipe |

|

Tank Material |

All quality inspected 304 stainless steel alloy |

|

Exterior Finish |

2B with all welds ribbon polished |

|

Interior Finish |

2B with all welds TIG welded with heat stain removed |

|

Tank Pressure |

Maximum 0.3Mpa |

|

All accessories on tank |

•Full sanitary sampling valve •TC Vacuum Pressure relief valve on top head •Mechanical relief valve 2 bar on CIP arm •Shockproof pressure gauge on CIP arm •Dry hopping port with solid end cap •Thermowell for high accuracy temperature sensor •Raking arm •carbonation stone •TC RSL Sample valve |

Delivery&Packing

We will choose Wooden case to protect the equipment from being damaged in transit.If the equipment’s height exceed the container’s height,we will put down the equipment and fix it by iron frame.

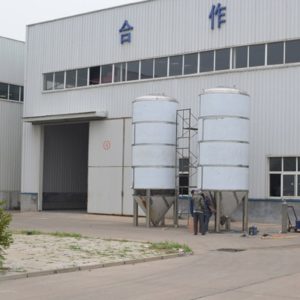

Company

Working shop

Certification

Certification

Contact us

If you have interest,please get in touch with me freely.