Description

1000L 3-vessel brewhouse system beer equipment overview

| Brewing system | Components | Specification |

| mill system | mill machine | double roller, low noise |

| mash system | mash/lauter tun |

inner shell:SUS304 TH=3.0mm exterior shell:SUS304 TH=2.0mm insulation:polyurethane TH=80mm Laser cutting V-wire false bottom Easy clean and detachable sparging sparing side manhole for spent grains |

| boiling/whirlpool tun | ||

| hot water tank | ||

| Heating system | boiler | electric,gas, diesel |

| Fermentation system | fermentation tank |

dome top and cone bottom, bottom cone 60 degree inner shell:SUS304 TH=3.0mm exterior shell:SUS304 TH=2.0mm insulation:polyurethane TH=80mm test pressure:3bar, working pressure:1.5bar top manhole or side manhole |

| Cooling system | glycol water tank |

use for cooling wort, fermentation tanks and bright tank |

| chiller | world-famous brand, use for glycol water tank | |

| Cleaning system | disinfection tank/alkali tank | equip with electric heating elements, clean for all the tanks |

| Control system | mash/fermentation/coolling | control all the tank’s temperature,motor and pump’s show on/off |

Brief introduce of the 3-vessel brewhouse system:

1-mash/lauter tun

mash tun with ABB VFD motor, false bottom, spary cleaning ball, sparing ring, raker, manhole

lauter tun with raker and wort pump with VFD ABB motor to adjust the speed.

laser cutting sieve plate with the gap 0.7mm and thickness is 4mm

Spent grain hatch, sight glass, top glass manhole

2-Boiling/whirlpool tun

In application of advanced boiling to improve the boiling intensity, promote coagulation such as proteins and the other solida, so that rapid separation of boiled wort.

To design according to the best program of rotating separation, enlarge the proportion of the height abd diameter, reduce speed to achieve the best separation.

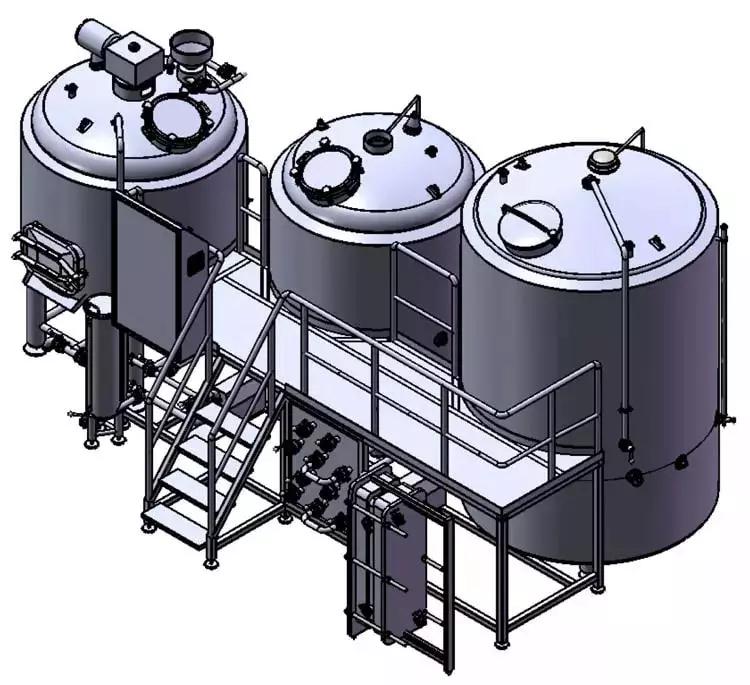

3-vessel brewhouse system

3-vessel brewhouse system 3D drawing

Brief introduction of the Beer fermentation tank:

All the main tanks and accessories of the beer brewing systems are all produced in food grade stainless steel. They are all produced with mature technics to guarantee the quality and using. We also supply service of installation, when you get all the equipment, you just need to learn how to use it.

stainless steel fermentation tanks

Features:

1.Insulated, keeping temperature automatically;

2.With cooling jacket;

3.Conical bottom;

4.Keeping and regulating pressure automatically;

5.No dead angle on the whole tank;

6.With dry hops pot.

The capacity of fermentation tank we could supply:

100L to 10000L

carbonation stone, side manhole, mechanical regulator valve

sample valve & drain outlet

If you have interest, please feel free to contact me.