Description

Today, we’ve supplied more than 1,000 tanks to the industry, ranging in volume from 50 to 20,000 litres. Customers turn to us for an incomparable combination of high-standard craftsmanship, practical functionality, and brilliant design. Each winemaker is different. Each has different needs when it comes to space, configuration, and aesthetics. We work with each client to design and build tanks that will fit their needs—and their budget.

Beer Brewing Process

Beer brewhouse system configuration:

| Mash/Lauter tun installed mash agitator, rakers and false bottom for grains separation. |

| -Usage: Mashing, mixing-stainless steel mixer driven by frequency convertor, lautering-eparation of mash grains from wort during wort producing process. |

| Kettle/Whirlpool tun wort boiling and make wort whirlpooling. |

| -Usage: wort boiling and whirlpooling. -Wort Whirlpool-sanitary centrifugal mash pump activate the whirlpooling. -Heating: electricity, gas fired or steam |

| Hot water tank water heating and hot water storing/preparation. |

| -Connected to the controller for automatic temperature controlling. |

Commercial 1000L beer brewhouse equipment for sale

Beer brewhouse system details

| Structure: | 1000L mash/lauter tun+1000L kettle/whirlpool tun+2000L hot liquor tank |

| Capacity: | 1000L |

| Dimension: | Φ1400x2500mm |

| Material: | Stainless steel 304 |

| Heating Way: | Steam heating/electric heating/direct fire heating |

| Electric Power: | 3 Phase,/380V,50 HZ |

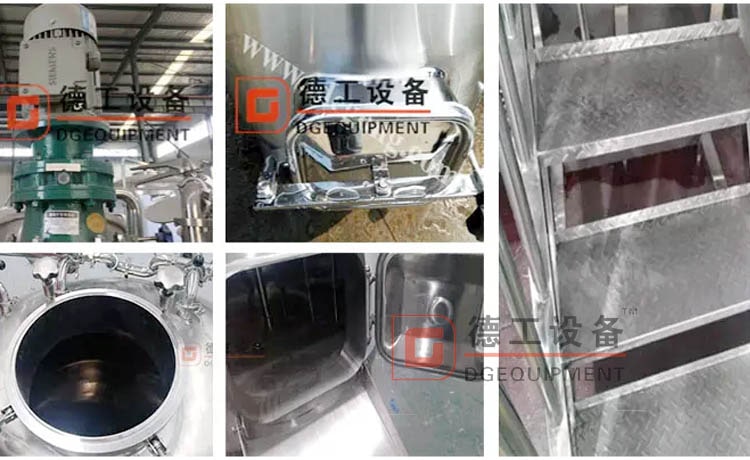

Siemens motor;Spent grain hatch;Stairs with handrails;top manhole;

The function of beer brewhouse is processing the grist and water into the wort which is ready for fermentation. We offers varying levels of automation and customization of two, three and four vessel brew house configurations. We focus on the design and structure of the brew house, which is the reason why we have to confirm all drawings of the equipment at the first beginning. All auxiliary equipments can be added or removed according to your requirements. Platform can be chosen, ABB/Danfoss frequency variable motor, We aim for your success! Just let me know if you are searching beer brewhouse.

Contact Alice Today

Talk to us about your requirements and we will design a system to work for you and your company.