Description

Whether you are a start-up, a well-established craft brewery or a market leading brand – you can benefit from DGET in the brewery industry. Our catalog of high-quality equipment ranges from complete systems to process units to components.

| BREWERY Brewhouse system features: |

2 vessel brewhouse with bright appearance

Mash/lauter tun(Brewery equipment)

- 150 dgree bottom design

- Grist hydrator

- Retractable lautering rakes with spent grain plow assembly

- Actuated knife-gate valve for spent grain removal

- Multi-port wort draw off plumbing

- Optional side steam jacket

Brewery equipment

Brewery Brewkettle/whirlpool

- Steam Jackets

- Optional external calandria for accelerated boil

- Vent stack condenser

- Kettle sour capability

- Tangential inlet design

- Re-circulation plumbing to cool wort pre-whirlpool for hop additions

Brewery Liquor tanks

Hot and cold liquor tanks using either heating/cooling jackets or heat exchangers

20BBL hot liquor tank available

Platform

Custom layout options(Meet the ergonomics design)

Stainless steel working platform

Plate heat exchanger

| Fermenting system features: |

Brewery equipment fermenters in cellar

Fermenters features:

- All fermenters use dimple jacket technology and multiple zones to maximize glycol cooling performance, allowing the brewer to crash cool beers and maintain lagering temperatures.

- We manufacture fermenters in all the most popular sizes:5, 7, 10, 15, 20, 30, 60, 90, and 120 barrels, but can create any volume you wish, up to 320 barrels.

- Horizontal lagering tanks are available as well.

- A controls package is available which includes a temperature controller that mounts directly to tank and a glycol solenoid valve.

- Unitank kit available which includes carb stone and port for function as a brite tank if necessary.

A row of beer fermenters

Top manhole optional

Includes:

Pressure Relief Valve

Pressure Gauge

CIP System

Dry Hop Port Sight Tube

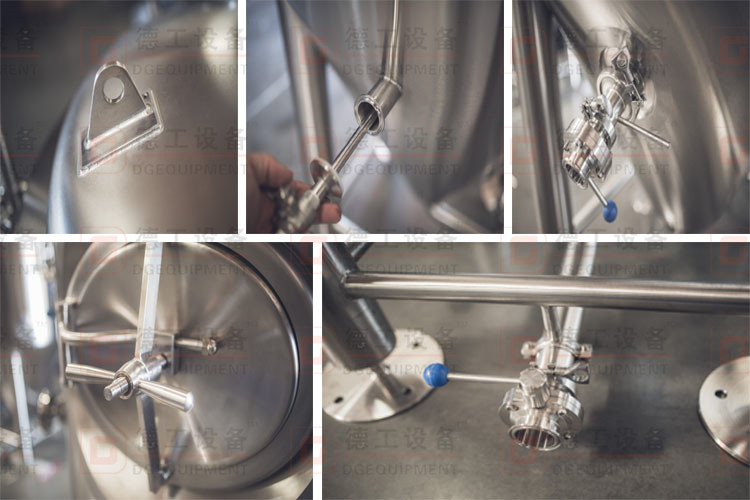

Fermentation tanks components

Lifting ear;carbonation stone;racking arm;side manhole;drain outlet

| Ancillary equipment: |

Complete grain management including:

Heat exchanger to cool the wort during transfer to the fermenter

Hot water recovery

Dedicated vessel pumps

| Roller mills | Augers and conveyors |

| Grist hoppers | Slide gates |

| Hydrators | CIP systems |

| Keg washers | Dry hopping systems |

| Yeast brinks and propagators | Boilers(electric;diessel;gas) |

| Glycol Chillers |

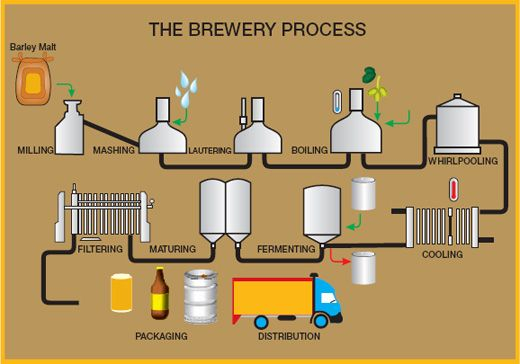

The brewery process:

Milling-Mashing-Lautering-Boiling-Whirlpool-Cooling-Fermenting-Maturing-Filtering-Packing

| DGET introduction: |

Our Services

1. ISO9001, CE certification.

2. Highly competitive price, more than 8 years production and manufacturing experience.

3. Our market team with our engineer with more than 8 years experiences together can satisfy you with any technology problem.

4. The seller is responsible for the nature damage of the machinery in the warranty period except for man-made damage.

TUV/ISO/CE Certification

If you would like to get a quotyation,do not hesitate to contact me freely.