Description

The heart of any brewery is an efficient and consistent brewhouse.Utilizing state-of-the-art, PLC’s and automation allows DGET to deliver semi-automatic or fully-automated brewhouses that deliver repeatable, efficient and high-yield brews at the right price.

2 vessel brewery equipment +hot liquor tank

| A complete of brewery equipment configuration: |

This system is a 3 vessel brewhouse design, shipped to the USA brewing market, can be used for microbrewery, beer factory brewing for different sized flavor beers. We recommend using mash/lauter, kettle/whirlpool. The hot liquor tank can be 20bbl, with double brews per day. The design is normally used in North American, EURO and Southern American brewing.

Note: 1US Barrel (BBL) =117Liter

Configuration:

1. Malt Milling Unit

Adjustable rolling crusher

Flexible auger for optional

Grains crusher or miller

2. 10BBL Brewhouse configuration

Every Weld Blended and Finished to a Smooth Sanitary Finish

Stainless steel brewing platform & integrated stairs or ladder with adjustable footpads for platform leveling

Stainless steel hard piping and brewhouse manifold with butterfly valves, Sight glass and all required clamps and gaskets to hook tanks together

Steam condensation stack with spraying nozzles.

Sanitary centrifugal pump for mash, wort or hot water transfer

Fixed speed or various speed agitator and rake for efficient lautering and spend grain removing

High Efficiency multi-pass plate type heat exchanger

Control panel in stainless steel with digital control and readout to programmable

V-Wire False Floor Included in Mash/Lauter Tun – virtually guarantees consistent wort flow

Compact- Space Saving and flexible Brewing Configurations

Eelectric heating or steam heating(Need a boiler:electric;gas boiler and diesel boiler are available)

Standard Thermometers and Thermawell Adapters

VFD controlling for pumps and motors

Level gauge (optional)

Ergonomic 10BBL brewhouse brewery equipment

3. 20BBL Hot liquor tank

Electric heating through electric tube

Sanitary centrifugal pump for hot water transfer

Level gauge (optional)

4. 10bbl Fermentation Unit

Standard stainless steel conical cylindrical fermentation tanks

Single size as brewhouse is common used in restaurant

Tanks quantity is exactly calculated by your brewing plan for various beers

All manhole, valves, pressure gauges, fittings etc are included

Brewery equipment fermenters can be available

5. Beer Filter Unit(optional)

In restaurant or bar, beers are always served as craft beer without filtration

6. 10bbl Brite tank

Standard stainless steel brite tanks for beer maturation, conditioning, service

Tanks quantity is exactly calculated for various beers and the function

All manhole, valves, pressure gauges, fittings etc are included

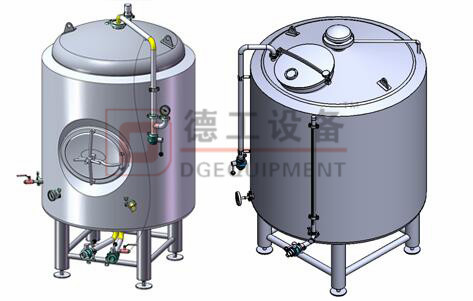

Brite beer tank model

7. Cooling Unit

Insulated glycol water tank with for glycol liquid holding and mixing

Efficiency chillers or refrigerators with Freon to supply cooling energy

Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

All pipes, fitting, insulation materials are include

Glycol tank and chiller

Technical parameters :

Construction is from SUS 304 food grade stainless steel, all pipes are SUS304

All tanks to be supplied with Data Plates including Test Data & Serial Number

All tanks will be tested and inspected in the NDT room after construction & Quality Control Checks

Jackets will be tested using water pressure testing, testing pressure: 0.3Mpa (3 Bar) & working pressure:0.2Mpa (2Bar)

All tanks will be pressure tested for 48 hours before leaving DGET’S factory;

The welds are full TIG welded

All tanks are mirror polishing inside, to be Ra 0.6um.

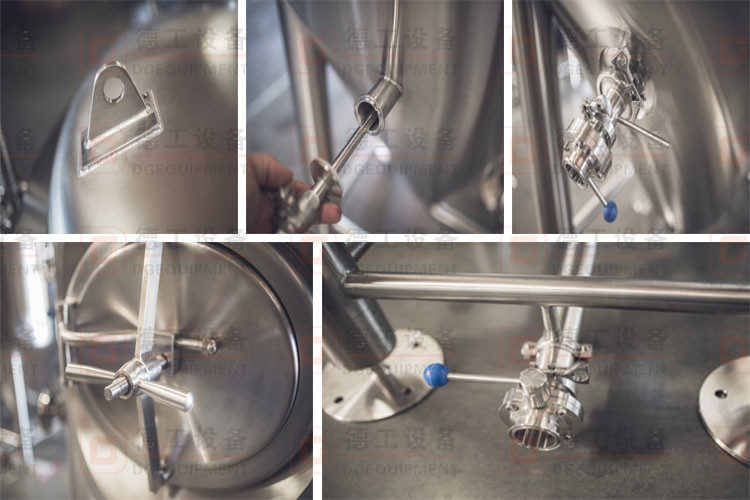

Brewery equipment brewhosue vessel details

(Bright stainless construction;large sight glass;top manhole )

Brewery equipment fermentation tank details

Brewery equipment fermentation tank details

(Racking arm;side manhole for checking;drain outlet etc.)

| DGET introduction: |

Whether you are a start-up, a well-established craft brewery or a market leading brand – you can benefit from DGET in the brewery industry. Our catalog of high-quality equipment ranges from complete systems to process units to components.

Our certification

After-sales service:

- After delivering the equipments to our customers, DEGONG will arrange special worker to do the track service, because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service.

- Within the warranty period, any malfunctions caused by the quality issues, DEGONG will be responsible to it.

- For the malfunctions beyond the warranty period, DEGONG will also be responsible to it, but the seller should take in charge of the expenses.

| Packaging & Delivery |

Packaging Details: standard wooden package

Package Type : As usual, we adopt wooden case as package type. It’s suitable for long-distance transport. According to customers’ special demand, we could adopt sheet iron case and so on.

Wooden box packaging,Load into container and fix

| Contact information: |

If you have interested about our craft brewing equipment, need a quotation or you simply want to discuss your project with us, get in touch and we will be happy to assist you.