Description

10BBl large beer brewery equipment is very popular for restaurant/brewpub/microbrewery.DEGONG 10bbl larbe beer brewery equipment will be designed and manufacturer based on highest Europe standard.We have sold many sets of brewing equipment in Europea,such as Germany,Belgium,Ireland,Sweden,Switzerland,Italy………All of our electric components is accord with UL certifications,and the whole set of equipment will be accord with TUV certification.

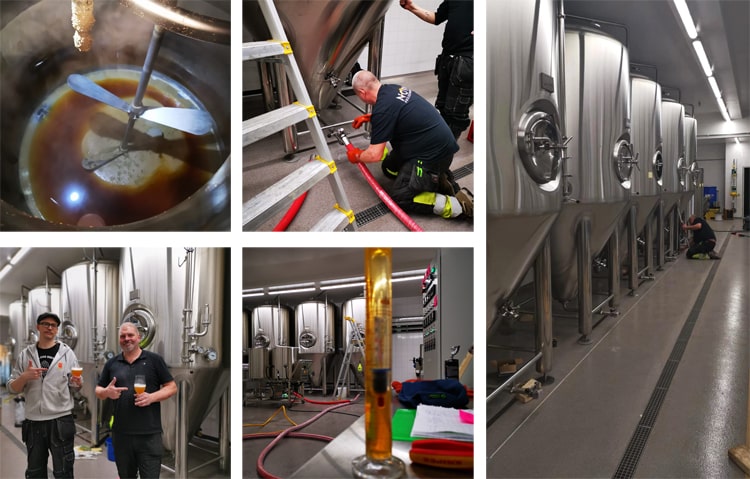

1000L copper brewery equipment in Ireland restaurant

500L copper brewhouse in Irish Brewpub

1000L Stainless steel brewing equipment in Sweden bar

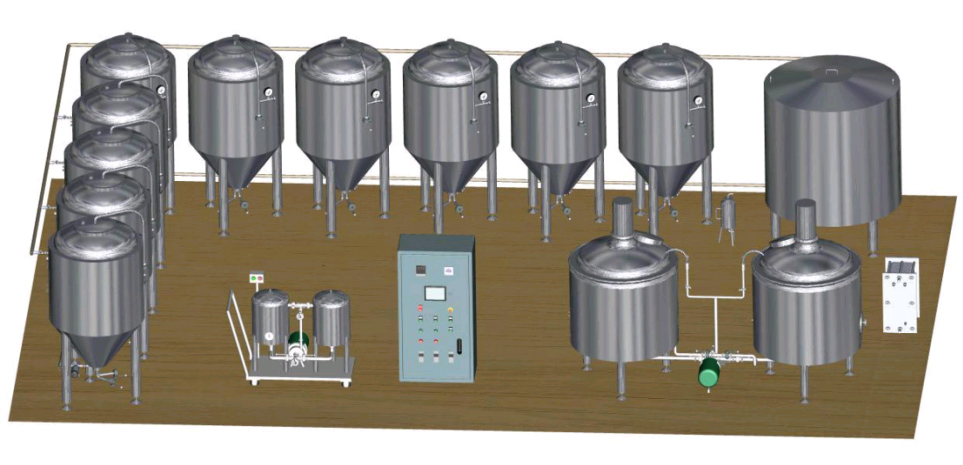

The large beer brewery equipment contains miller,brewhouse,fermentation system,cooling system,CIP cleaning system and control system.The brewhouse and fermentation tank are both the heart and engine of the brewery,which are key components in beer brewing progress.

Beer mashing system

The mashing system contains mash tank,lauter tank,boiling tank and whirlpool tank.You can combine them freely.

- 2-vessels:mash/latuer tank+boiling/whirlpool tank+double hot liquid tank(suitable for equipment less than 1000L)

- 3-vessels:mash/lauter tank+boiling tank+whirlpool tank+double hot liquid tank(suitable for equipment 1000L-3000L)

- 4-vessels:mash tank+lauter tank+boiling tank+whirlpool tank+double hot liquid tank(Suitable for equipment more than 3000L)

3-vessels beer mashing system

3-vessels beer mashing system

Features:

- 304 SS or 316LSS or copper.

- 30% head space at least for each tank

- ABB Siemens motors/pumps on the whole system

- Stainless steel process piping, work cabinet and control cabinet

- Grirst hydrator bowl with hot/cold liquor blending.

- Insulated with a minimum of 100mm Chloride-Free PU Insulation.

- Interior Finish: Overall polishing to 0.4 μm without dead corner

- Adjustable Levelers provide a level tank regardless of floor slope;

- Electric heating,steam heating or direct fire heating

Optional items include:

- Wort grants

- Dual-stage heat exchangers

- Wort oxygenation assembly with wight glass

- Hop backs

- Flow meters/totalizers

- Full skid mounting.

Fermentation tank

Stainless steel, vertical, double-walled, insulated, 60 degree cone bottom, dished head, beer fermentation tank.Cylindrical and conical parts have independent glycol cooling zones controlled by temperature sensor.Part of dished head forms oval manhole, breathing valve set up at 1.5 bar and sanitation cleaning ball. There is a manhole(Or side), a hops hole on the top of the tank.A pressure gauge and a mechanical safe valve are connected on the L pipeline.There are also a sample valve,a temperature sensor,a thermometer in the cylinder of fermentation tank.conical part has bottom outlet yeast removal pipe and outlet for beer transfer to serving tanks. Vessel is supported by 3 tube legs with fully articulating adjustable feet. Tank is also equipped at the top by 2 cable eyes for easier manipulation.

After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.