Description

Craft brewing system feature

Small covered area

Very little investment

Quick return of funds

Easy to operate, one brewer is enough for the entire system

Application: taproom/ hotel / restaurant / school / home

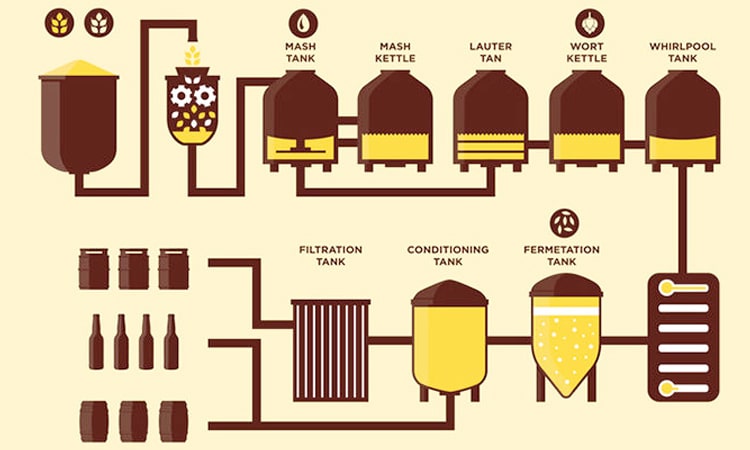

Craft brewing system process

Craft brewing system simple overview

Mash system is made of high-quality sus304, optional 2b or high-precision surface polishing.

Can be customized beer brewing system

Capacity: 5-20bbl or customized. Vessels:mash tun, lauter tun, boiling tun, whirlpool tun (Can be a variety of combinations. ). Heating:steam, electric, direct fire

You can choose the heating method that suits you.

Inner: sus304,thickness 3mm, 2b finished.

Outer: sus304, thickness 2mm, grind arenaceous.

Operation platform,pumps( frequency control), plate heat exchanger, wort aeration device, control box temperature controller, manual valves.

Optional:steam condensing pipe, grist hydrator, pneumatic valves, button control.

2-vessel: mash/lauter tun+boiling/whirlpool tun+hot water tank

2-vessel: mash/lauter/whirlpool tun+boiling tun

Craft brewing system constitute

Mash/lauter tun

Grain rake for uniform mashing

Grain out door with grain chute

Laser cutting false bottom

Grist hydrator for optional

Steam jacket for optional

Boiling/whirlpool tun

Steam, electric, or direct fire for heating optional

Steam condensor

Tangential whirlpool inlet

Hot water tank(optional)

Overflow protector

Auxiliary system

Malt rolling miller

Two stage stainless steel plate heat exchanger

Stainless steel 304 operation plateform

Look:preparation of wort

side manhole, stirring blades, false bottom, raker, spent grains hatch, sight glass, motor