Description

| 10BBL BREWERY EQUIPMENT |

Turnkey brewery model

Technical Description:

- This system can meet beer mashing requirements, including malt milling, mashing, Wort filtration, wort boiling, whirlpool, fermenting,cooling, control and so on.

- All tanks were made by SUS304, in accordance with the standard of food hygiene and safety standards.

- The tank is equipped with variable frequency mixer which can meet the requirements of rotating speed for mashing mixing and filtration tank mixing.

- Automatic control or semi-automatic control will design according with customer requirements.

- Input and output of material and circulation are connected by sanitation pump and hose.

- Connection type of pipelines for equipments is quick assembly which is convenient for cleaning, maintenance and repair during production.

- Reasonable design, nice appearance, durable service, easy for operation, repair and maintenance.

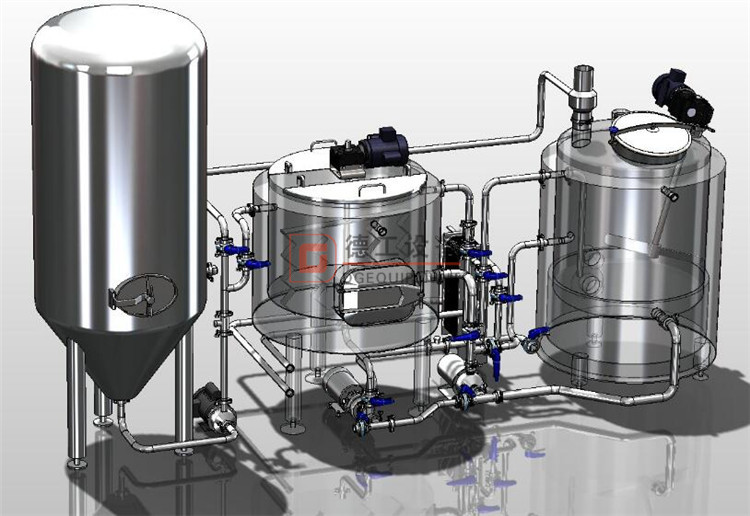

Turnkey brewery equipment Brewhouse system

Turnkey brewery Equipment constructure:

- DEGONG brewhouses consist of Mash/Lauter Tun,brew Kettle/Whirlpool Tun,Hot Water Tank

- The brewhouse was equipped with wort pump,hot water pump, plate heat exchanger, pipeline, valve and controller

- The brewhouse work together with fermentation tanks(6 pcs and upward), bright beer tanks(2-4pcs), water treatment,cold water tank, glycol tank, malt milling, screw conveyer,steam generator, CIP system, beer keg washer, beer filling machine, beer sealing machine…

Technological Parameter:

Output: 10BBL/brew

Batch: 2-6 batch/week

Customized fermentation tanks

Design Philosophy:

Centralize control, manual control and automatic control work together. Reduce investment, water saving, energy saving, low consumption, high efficiency.

Turnkey brewery Equipment Features :

- To save the hot water from heat exchange plate to hot water tank for feeding material, grain washing and cleaning.

- Exhaust pipe for kettle tun will condensate the steam to water, this method will avoid to cause environmental pollution, we can use the water to wash floor.

- Mashing and filtration in one tank will save time and reduce wort oxidation.. Stagger scraper spindle head to help scraper to a high level, this design reduce work obstruction and save more energy. back purge system locate the bottom of tank will wash the bottom of tank more clean.

- Brewery equipped with hand control or automatic control.

- Perfect and smooth process design make the whole equipment compact and easy to operate

| Location: | China |

| Business Type: | Manufacturer, Exporter |

| Brands: | Degong |

| Terms of payment and delivery: | FOB QINGDAO Port |

| Minimum order quantity: | 1 Set |

| Price: | Consultation |

| Packing details: | Wooden box for each tank |

| Delivery time: | 20-45 working days after contract confirmed |

| Payment method: | T/T |

Turnkey brewery Brewhouse details

Turnkey brewery Fermentation tank details

If you want to get a quotation for brewing beer equipment,don’t hesitate to contact me. I will calculate the turnkey brewery price for you after receiving your specific requirements. Welcome !!!

| Contact Alice today |

Talk to us about your requirements and we will design a system to work for you and your company.