Description

Beer brewhouse of 10HL craft brewery plant introduction

Brewhouse contains mash tun, lauter tun, kettle, and whirlpool. Depending on the production needs, physical size and scale of the operation, brewhouse construction are fully customizable for each buyer,such as “Mash/Lauter tank+Boiling/Whirlpool tank+Hot water tank.We can provide you with a turnkey 10hl craft brewery plant setup, we can also customize a brewhouse to your specific needs. If you aren’t sure what you need, we can help guide you to choose a system that fits both your production requirements and budget.

1.Mash/Lauter tun of 10HL craft brewery plant

Our mash/lauter tuns can be used in a variety of mashing methods and are designed to give you an optimum combination of good extraction, high gravities, and efficient lautering.

We offer motorized rakes and plows on many of our mash/lauter tuns to help break up the grain bed and make it easier to grain out. All of our mash/lauter tuns come standard with sanitary tri-clamp fittings for easy cleaning and production of high-quality wort. Each mash/lauter tun is sized to get the proper grist to water ratio for a high gravity beer without overflowing.

2.Brew Kettles/whirlpool tank of 10HL craft brewery plant

Our brew kettles are made from premium stainless steel 304 . We have designed a unique combination brew kettle and whirlpool tank, which allow you to separate the hot break from the wort prior to cast out. The dished bottom of the stainless brew kettle and a tangential inlet allows you to effectively stir your wort by pumping it from the regular outlet and back into the brew kettle via the inlet.

Specifications

SUS 304/SUS316/Copper clad,Inner Thickness=0.3mm,Outer thickness=0.2mm

Optional heating style of steam, electric and direct fire for brewhouse tanks

Designed headspace, over 30%

Internal 2B finishing, welds polishing to 0.4um

Cylindric and bottom with steam jacket–Max 3 bar pressure ensures 1°C/min heating speed.

VFD controlled reducer and wort pump

Assembly sanitary rotary spray balls for cleaning

PU insulation,thickness:100mm

Temperature sensor(RTD) in a thermowell

Packing&Delivery

Standard packing:

Cord ,film membrane

Firm membrane, wood box for free fumigation

Delivery :

– We put your order into our tight production schedule to ensure the punctual delivery time.

– Production or inspection report before order packed.

Service

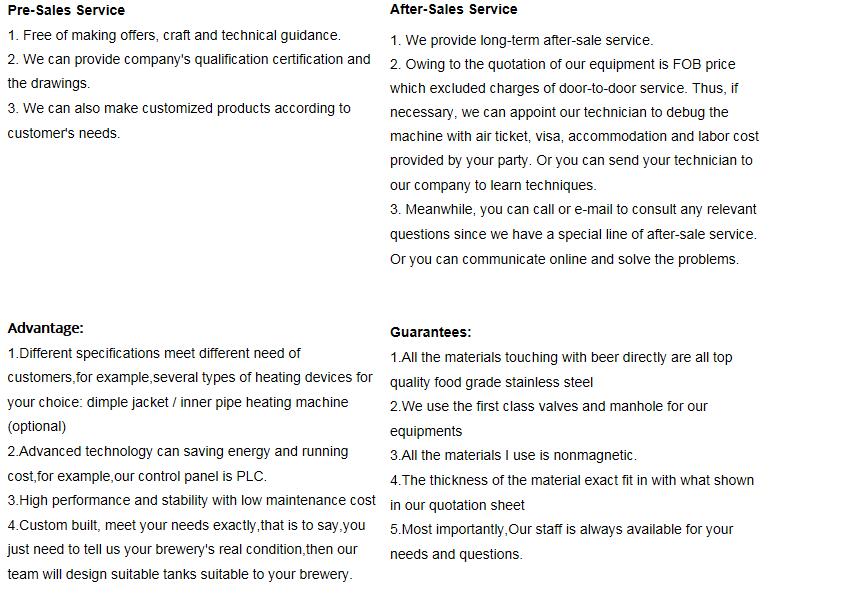

Contact us