Description

The 10HL craft steel beer brewing equipment is a popular model for customer. It is not too big and not too small,so it can use for both commercial used and private brewery. In addition,10HL beer brewing equipment’s production range is wide and the output is according to the number of fermentation tanks.

The craft steel beer brewing equipment includes miller, mashing system, fermentation system,cooling system, control system and CIP system. Each system’s configuration is according to customer’s needs, such as 2 brewhouse or 3 brewhouse, steam heating or electric heating, etc. . . . .

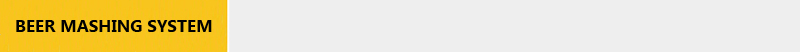

10HL 2 Vessels beer mashing system craft steel beer brewing system for brewpub

Brewhouses/beer mashing system several key pieces of brewing equipment. The whole brewery mashing plant has four function,which is mash,lauter,boiling,whirlpool. In the operation of the brewmaster.convert grain that has been milled through a specialty grain mill, into sweet liquid (we usually call it wort )”. Wort is subsequently fermented and finished in specialized beer tanks called fermenters and brite tanks.

Configuration:

Milling: 2-roller or simplified 4-roller

Mash &Lautertun: Brewing &sparging water blending port, VFD rake, with wort grant, mash hydrator, etc

Kettle & Whirlpool: Dimpled steam jackets or direct burning heating, as well as electric immersion heating

Hot Liquor Tank: Steam heating, direct burning or immersion electric heating.

Pumps: Lautering pump and whirlpooling/castout pump of VFD, HL pump

Piping: Tri-Clamp or DIN standard pre-built

Heat exchanger: 2-step or 1 step, with fittings such as thermometers, venturi aeration unit, etc

Brewhouse control: VFD, switches etc, Automatic Temp. control, etc

Specifications

SUS 304/SUS316/Copper clad,Inner Thickness=0.3mm,Outer thickness=0.2mm

Optional heating style of steam, electric and direct fire for brewhouse tanks

PLC control panel with Siemens,Omron,Schenider element,and accord with EU standard

VFD control reducer and wort pump

Grist hydrator with strike water mixing station

Plate heat exchanger for cooling wort

Grant /hop guns for filter or storage first wort

Independent hot liquor tank or combine with brewhouse tanks

Independent cold liquor tank

Top glass manhole for checking mashing condition

Sight glass to check if the wort is clean

Wort oxygen system

2D/3D engineering for brewery set up simulation

Raker and false bottom

Raker and false bottom

automatic spent grain removable

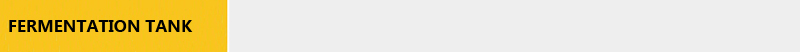

10HL Stainles steel conical Unitank fermentation tank for sale

Fermentation tanks, or more commonly fermenters, are key components in beer brewing. Fermenters are specilized tanks designed to precisely control temperature and maintain the optimal conditions for fermentation, which occurs once the wort transfer from the brewhouse to the fermenter; a conical-bottom design for fermenters is allowing for easier yeast harvesting.

Specifications

100% food-grade 304 and 316 stainless steel

All fermenters are rated to 14.7 PSI (1 bar) operating pressure

Two-zone glycol jacketing encompasses the 60-degree conical cone and sidewalls

Top-mount manway (optional side-mount configurations available)

Complete thermal insulation of side walls and cones

All insulation is fire retardant fiber cloth (not foam)

All welds are blended and finished to a sanitary food-grade finish

Every fermenter is equipped with:

racking arm

pressure relief valve

blow-off/ clean-in-place (CIP) tube

CIP spray ball

sample valve

butterfly valves

TC clamps, gaskets and clamps

90-degree elbows

optional rupture disc assemblies available

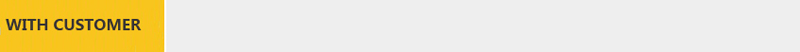

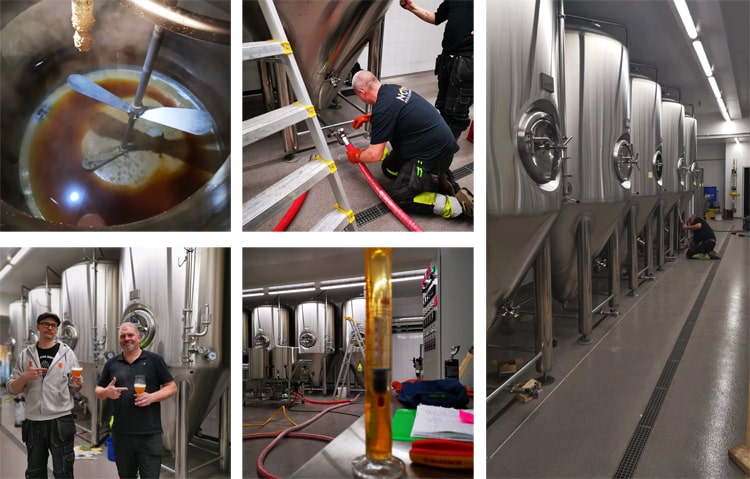

We will dispatch engineer to install equioment in your area.If you need,they will teach you how to brew beer

If you have interest in our equipment or you want to know more about beer breiwng,feel free to contact us