Description

10HL stainless steel craft beer brewing equipment for sale

|

Equipment Request |

Components |

|

1. Milling System |

Malt Miller |

|

2. Mashing System |

Mash/Lauter Tun |

|

BoilingTank |

|

|

Whirlpool tank |

|

|

Heat exchanger |

|

|

Wort Pump |

|

|

Stirring Device (Optional) |

|

|

Other accessories are available: 1. Ornamental Pipe; 2. Mashing Pipeline; 3. Operating Platform; 4. Yeast Feeder; 5. Venturi Tube; 6. Butterfly Valve DN40; 7. Butterfly Valve DN32; 8. Soft Pipe; 9. Dregs Rake; 10. Sugar Measuring Cylinder; 11. Saccharimeter; |

|

|

3. Fermenting System |

Fermentation Tank |

|

Other accessories are available: 1. L-Pipe; 2. Butterfly Valve; 3. Pressure Gage; 4. Solenoid Valve; 5. Vacuum Valve; 6. Cooling Pipe; 7. Thermal Insulation Pipe; |

|

|

4. Cooling System |

Ice Water Tank |

|

Refrigeration Machine |

|

|

Centrifugal Pump |

|

|

Evaporator |

|

|

Ice Water Pump |

|

|

Relative Pipes and Valves |

|

|

5. CIP System |

Washing Tank |

|

Sterilization Tank |

|

|

Pump and Valve |

|

|

6. Filter System |

Kieselguhr Filter |

|

Membrane Filter |

|

|

Filtered Beer Tanks |

|

|

7. Packing System |

Fresh Keg Packing Machine |

|

Pop Can Packing Machine |

|

|

Glass Bottle Packing Machine |

|

|

8. Controlling System |

Mashing Control Panel |

|

Fermenting Control Panel |

|

|

Refrigerating Control Panel |

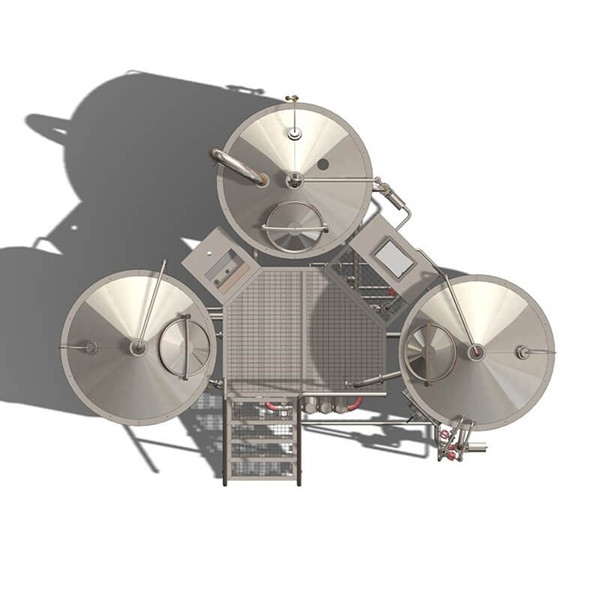

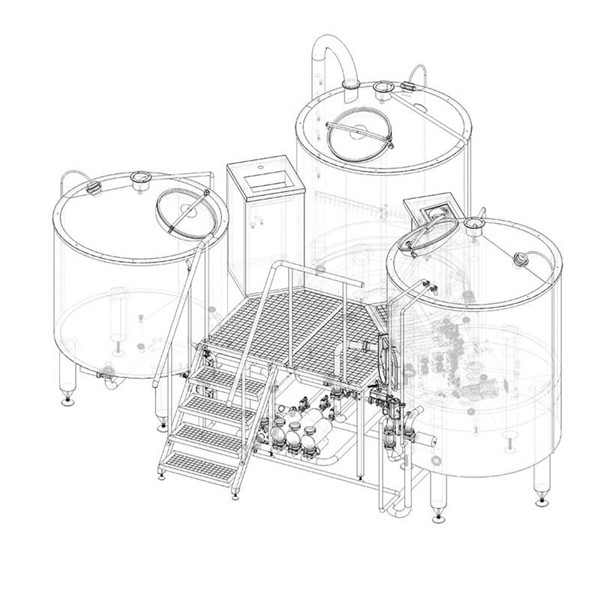

Brewhouse system of beer brewing equipment

Features of brewhouse:

– All tanks are made of food grade stainless steel 304.

– Adopting advanced world famous brand components in electric parts and operation parts.

– ABB motor for wort pump

– ABB/Siemens motor for raker and blender

– PLC automatic control method

– The structure of brewhouse: 2-vessel, 3-vessel or 4-vessel (Optional)

– Thickness: inner 3.0mm; out 2.0mm; jacket: 1.5mm

– Insulation: Polyurethane thickness: 100mm

– Working pressure: 1.5-2.0 bar Design pressure: 3.0 bar

– Inner surface treatment: welds grinded to Ra0.4µm without dead corner

– Outsourcing surface: weld polishing processing

– Heating method: steam; electric; direct fire (Optional)

Fermentation tank of beer brewing equipment

Features of fermentation tank:

– All tanks are made of food grade stainless steel 304.

– Certified stainless steel material

– Adopting advanced world famous brand components in electric parts and operation parts.

– Thickness: inner 3.0mm; out 2.0mm; jacket: 1.5mm

– Insulation: Polyurethane thickness: 100mm

– Insulated with high efficiency polyurethane foam

– Working pressure: 1.5-2.0 bar Design pressure: 3.0 bar

– Cone 60° resist compression design

– Fermentation pressure controlled by pressure gauge automatically.

– 100% TIG welding with pure argon gas shield.

– Quality TIG welding: for piping, quality TIG welding with sanitary interior shapes

– Glycol jacket: dimpled plate on cone and side

– Heat exchange area: 2.69 square meter

– Interior surface: mirror polishing

– Exterior surface: oil bushed finish

– Interior full polished to Ra0.6µm without dead corner

– TC connected CIP arm with 360° coverage spraying ball

Contact us