Description

10HL stainless steel industrial beer fermentation tanks for sale

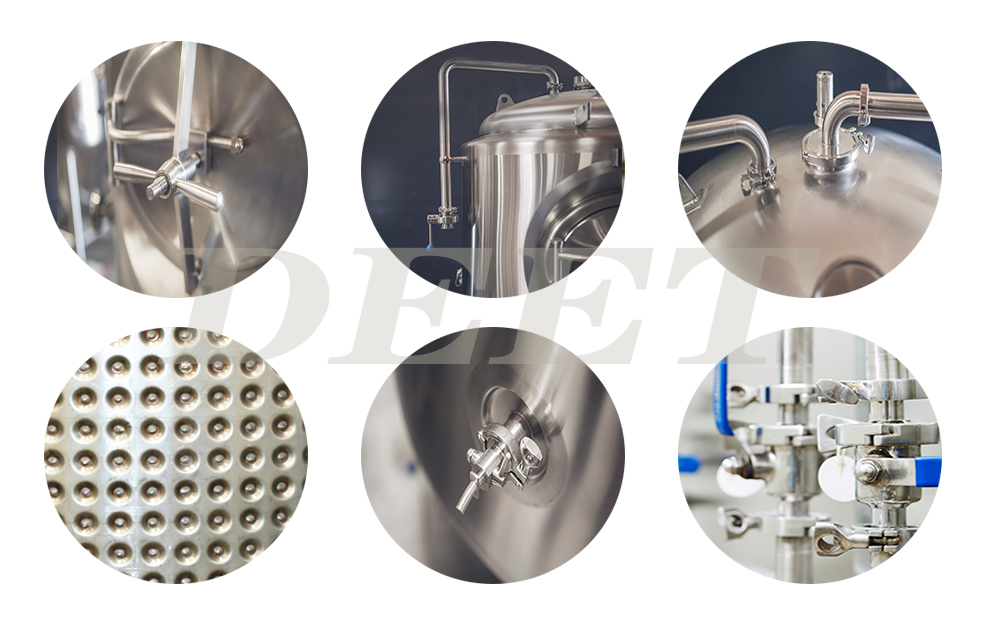

Beer fermentation tanks features:

- All connections are fully welded Tri Clamp fittings

- 0.12 –0.15Mpa operating pressure; 0.3Mpa design pressure

- Pressure gauge

- Versitile port for dry hopping, CIP, and the pressure relief valve

- Sampling valve

- Thermowell for thermometer

- Carb stone with 1/4 in ball valve

- Blow off cane ,ball valve

- Polyurethane insulation jacket

- Custom ss butterfly valves with racking arm

- Stainless lower shelf

- Adjustable feet

- 10HL operating volume; 1300L max volume

- Made from 304 stainless steel

Technical parameters:

a.inner thickness:sus 304,3mm

b.outer thickness: sus 304,2mm

c.jacket:sus 304,1.5mm

d.insulation:polyurethane 100mm

e.inner sueface treatment:welds grinded to Ra 0.6um

f.outsourcing surface:weld polishing processing

g.jacket pressure:design pressure:0.3Mpa,working pressure:0.12-0.15Mpa

Our survice:

a. Design: DG engineers is providing various types of brewing design services according to cutomers’ requirements.

b. Testing and Maintenance: professional equipment and application product testing and maintenance services according to actuall working conditions.

c. Directed: transforms demand into the latest solutions and products with our advanced technology to help clients build core competitiveness.

d. Project Evaluation: this assessment includes all the elements of in mind project including advantage, technology, efficiency, quality control etc.

e. Continuous Service: actively provide pre-sales, sales, after-sales service and value-added services to help customers enhance value.

f. Training and Improvement: carries on the thorough training to the user, in order to maximize the equipment and the product functions.

Quality control:

1. All tanks will be pressure protection 48 hours before leaving from factory;

2. All the welds are TIG full welded, dimpled jacket by using water to weld to make sure uniform to be long life.

3. All tanks are mirror polishing inside without dead corner, welds grinded to Ra 0.4um.

4. All the manholes and clamps gaskets will be sanitary.

Our factory:

Aplication:

If you are interested in our brewery equipment,please feel free to contact me.