Description

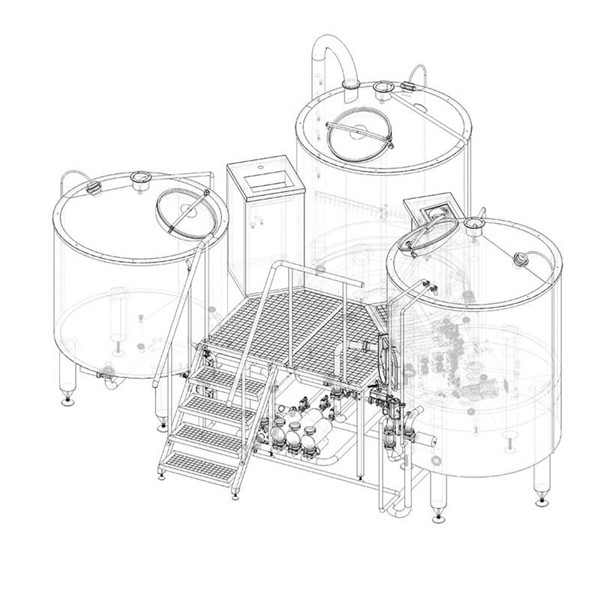

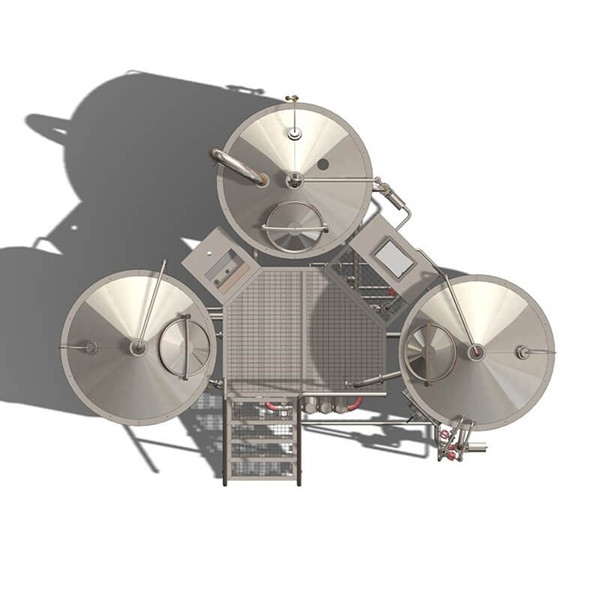

2 vessel commercial beer making equipment

Commercial beer making equipment

| Material for brewing beer | |

|

Grains |

Grains form the foundation on which beer is built. They lend flavor, aroma, color and mouthfeel to beer. They also provide the raw ingredients needed for the yeast to create alcohol. Quite simply, without grain, there is no beer. |

|

Hops |

While grains form the backbone of all beers, if left unchecked, they can cause a beer to become undrinkably sweet. That is why brewers add other ingredients, usually something bitter, to counterbalance the malt.Hops are the main source of bitterness in beer. |

|

Water |

Many people completely forget about water when listing the components of beer, even though it usually represents over 95% of the final product! More than a simple vehicle for holding the other ingredients, water lends many essential, if overlooked, characteristics to beer. |

|

Yeast |

Once introduced into unfermented beer (wort), yeast will immediately begin to consume the sugars from the malt. Yeast convert this sugar to alcohol, with an added byproduct being carbonation. To put it more crudely, yeast eat sugar, pee alcohol and fart carbonation! |

| Basic technical parameter | |

|

Material |

SUS304/red Copper |

|

Application |

Brewpub Beer Brewery Restaurant |

|

Function |

Brewing beer |

|

Shell |

Mirror Polished |

|

Brewing System |

2 vessels, 3 vessels, 4 vessels |

|

Heating method |

Electric/Direct Fire/Steam Heating |

|

Heat preservation method |

Polyurethane insulation layer |

| Interior thickness | Stainless steel 3.0 mm, |

| Exterior thickness | Stainless steel 2.0 mm |

| Insulation | Polyurethane, thickness 100mm |

|

Cooling System |

Glycol / Ice water tank&Chiller |

|

Control System |

PLC/PID |

|

2-vessel brewhouse |

2-vessel brewhouse configuration offer brewers a simple and cost effective solution. Through combining mash tun & lauter tun, and kettle & whirlpool into a 2-vessel solution, it will help you on space and cost saving without compromising brewing quality and control.

|

|

3-vessel brewhouse |

3-vessel brewhouse configurations offer brewers a more efficient and faster brewing solution and achieve multi temp. control for step mash. It can be comprised by mash/lauter, kettle/whirlpool, and hot water tank.

|

|

4-vessel brewhouse |

4-vessel brewhouse configuration offer brewers a professional and higher performance brewing solution for multi batches brew per day. It is comprised by mash, lauter, kettle, whirlpool. DG’s 4-vessel brewing system offer you options of semi-auto or automation controlling and overall flexibility.

|

Application

Certification