Description

Gas heating brewing equipment brief introduce

Gas heating brewing equipment is made of SUS304 stainless steel.The cooling jacket adopts dimple jacket. The jackets are provided at tank body and conical bottom to effectively increase the cooling speed. Heat exchanging area of jacket of different proportions can be allocated according to customers’ technological requirements. Widly used in brewery,bar, hotel etc.

Gas heating brewing equipment overview

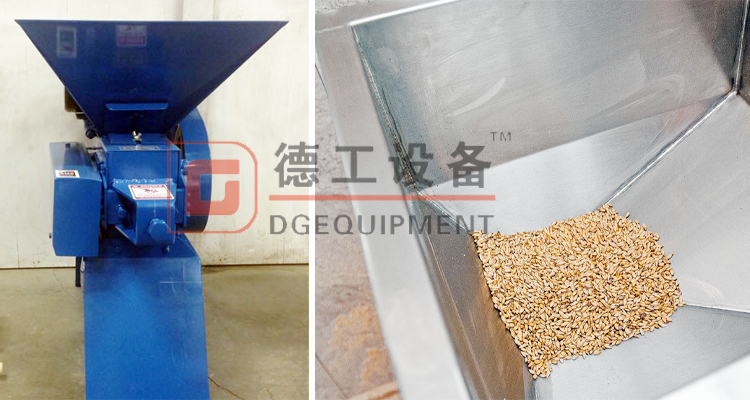

Grain mill system (mill machine)

Malt and grain raw materials can be well dissolved after being crushed, and the crushing quality plays an important role in the composition of wort, wort filtration and raw material utilization in the mash process.

Mash system brief description

Mash tun, Lauter tun, Boiling Kettle, Whirlpool tun in various combination

Hot water tank and cold water tank for optional in special combinations

For 1500L brewhouse, we recommend mash/lauter tun+boiling/whirlpool tun+hot water tank

Infusion or decoction brewing methods are designed exactly

Two stages or single stage heat exchanger for wort cooling

Completely stainless steel integrated work platform

Sanitary and efficiency wort pump

Gas heating brewing equipment mash system details

Mash/lauter tun

This tank has a mixing paddle to ensure that the mix of water and malt is constantly agitated during mashing.The malt is mixed with hot water to allow the starch to be converted into sugar by enzymes. We have steam jackets on the outside of the tanks to heat the mash in stages.This mashing process takes about two hour.

The sweet liquid, now called wort, can pass through the screens of the false bottom, while the grain stays behind. The wort is then pumped into the kettle.This process takes about 1.5 hours. Afterwards, the spent grain is collected for pig feed.

Boiling/whirlpool tun

Once all the wort is in the kettle, the liquid is boiled for 60-90 minutes. This ensures that the wort is sterile.Hops are added to the kettle at the start of boil for bitterness and at the end of boil for aroma and flavour.

The wort is then recirculated through a whirlpool effect which ensures the residual hop product and proteins and enzymes are coagulated, and settle out of the liquid as a sludge called solids sediment.

1500L/3000L fermentation tank more information

Material:stainless304/316

Racking Arm and discharge port with butterfly valve and fittings;

dimple plate cooling jacket.

Insulation thickness: 100mm

Inner tank thickness: 3.0mm; outer thickness:2.0mm

CIP arm and rotary spray ball

Release and breath valves

sample valve, mechanical pressure regulation valve

Pressure gauge & Thermometer & Sample valve

Dimple plate cooling jacket with glycol inlet and outlet

Four legs with brace and adjustable bolt

Interior of tank is mechanical polished, inner body polishing ratio 0.4μm. Out plate surface protection welding line Belt Sander Polished,welding: 100% Argon Arc welding.

Cooling system (glycol water)

Function: Used for cooling wort in heat exchanger when it finished the mashing in brewhouse, and cooling wort in fermentation tank in the fermenting period.

Component: Ice water tank, solenoid valve, glycol water ump, stainless pipeline and etc.

Cooling method: Two stage cooling (Glycol water and tap water work cooling).

Control method: Automatically by PLC controller cabinet.

In addition to glycol water, the cooling system also includes refrigeration units, circulating pumps, etc.

If you are interested in beer brewing equipment, please feel free to contact me.