Description

1500L commercial stainless steel conical customized fermenter

Fermentation system is one of the key links in beer brewing.

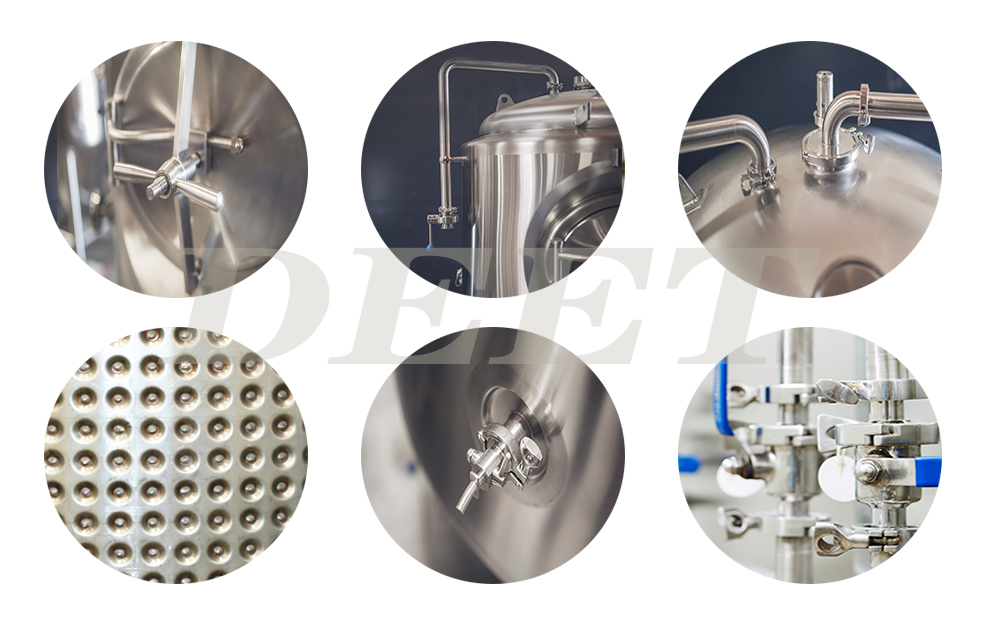

The cone section of our fermentation tank is 60 degrees, which makes it easy to get a clear beer, while the other substances can be discharged smoothly through the sewage outlet.

Manhole:If there is no hops adding port, we can also add through manhole.In addition, manhole can enter people, for the later maintenance and cleaning of equipment is of great significance.

Pressure gauge:The pressure gauge can show the pressure in the tank in real time

Mechnical valve:When the pressure is set, the valve releases gas to keep the tank safe.

Breather valve:Breathing valve is the second safety barrier, when the internal pressure is greater than the external pressure, it will release pressure to the outside;When the external pressure is greater than the internal pressure, it will also exhaust into the tank.In a word, it is a process of balancing internal and external pressure to ensure the safety of the tank.

Temperature probe:The temperature probe is used to observe the fermentation temperature in the fermenter.

- Made in stainless steel 304

- Volume 1500l (We can design according to customer’s requirements)

- 60 degree cone

- Double wall sus304

- Cooling jackets in cone and cylinder

- Four adjustable feet

- All necessary connections for sampling, spunding, pressure valve and security valve (pressure and vacuum)

a. Design: DG engineers is providing various types of brewing design services according to cutomers’ requirements.

b. Testing and Maintenance: professional equipment and application product testing and maintenance services according to actuall working conditions.

c. Directed: transforms demand into the latest solutions and products with our advanced technology to help clients build core competitiveness.

d. Project Evaluation: this assessment includes all the elements of in mind project including advantage, technology, efficiency, quality control etc.

Contact us