Description

35HL craft stainless steel customized beer making machine for sale

| 2-vessel brewhouse | 2-vessel brewhouse configuration offer brewers a simple and cost effective solution. Through combining mash tun & lauter tun, and kettle & whirlpool into a 2-vessel solution, it will help you on space and cost saving without compromising brewing quality and control. |

| 3-vessel brewhouse | 3-vessel brewhouse configurations offer brewers a more efficient and faster brewing solution and achieve multi temp. control for step mash. It can be comprised by mash/lauter, kettle/whirlpool, and hot water tank. |

| 4-vessel brewhouse | 4-vessel brewhouse configuration offer brewers a professional and higher performance brewing solution for multi batches brew per day. It is comprised by mash, lauter, kettle, whirlpool. DG’s 4-vessel brewing system offer you options of semi-auto or automation controlling and overall flexibility. |

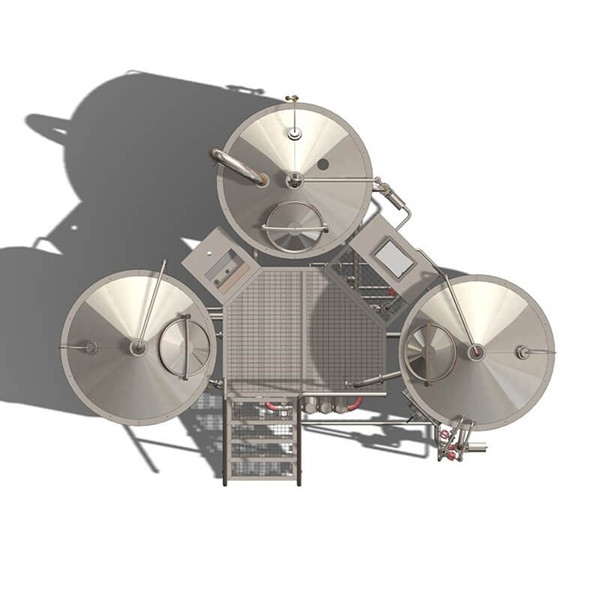

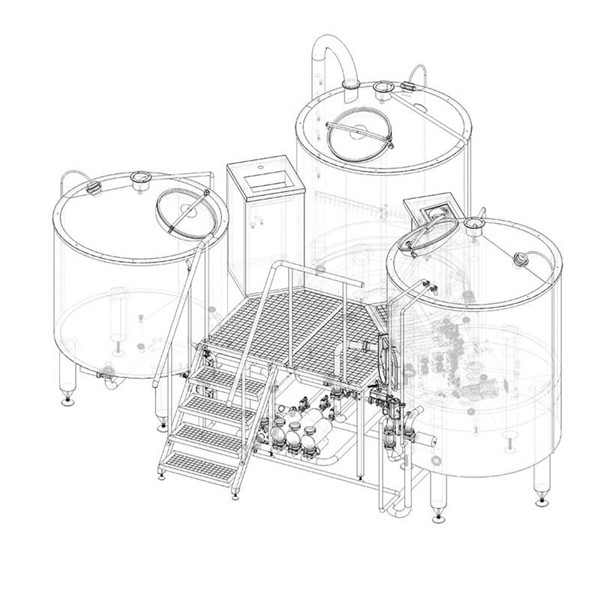

Detailed drawing(Beer making machine)

Main Configuration

35 HL mash tun with steam heating

-2mm exterior shell and 3mm interior shell

-Glass manway

-Agitator with VFD controled motor and turbine reducer

35 HL lauter tun

-2mm exterior shell and 3mm interior shell

-Glass manway

-Grain rake with VFD controled motor and turbine reducer

-Automatic lifter of spent grain scraper blade

-Inline wort lauter sight glass

-Laser cutting V-wire False Bottom/Filter

-Bottom mounted grain outdoor

35 HL brew kettle with steam heating

-2mm exterior shell and 3mm interior shell

-Glass manway

-Agitator with VFD controled motor and turbine reducer

-Sanitary leveling sight glass

-Steam vent with condensate ring for kettle stack

35 HL whirlpool tun

-2mm exterior shell and 3mm interior shell

-Glass manway

-Anticlockwise Tangential whirlpool inlet in Northern Hemisphere

-Clockwise tangential whirlpool inlet in Southern Hemisphere

Other auxiliary equipment

-70 HL hot liquor tun with steam heating

-1200L cooker

-flexible auger/bucket elevator

-2450L hoppper and a malt hydrator

-Pneumatic valve

-Flow meter

-Hop back

-Sink and platform

-35m2 heat exchanger

-PLC control with touch screen

After-sales Service Provided:

2 years of tank and 6 months of accessories guarantee, lifelong maintenance at cost charge

7×24 hours per week email&phone available

Maintenance, return & exchanges services

Package:

Each tank is wrapped with blanket and wooden, lay down on steel saddle in the container,and is braced by steel wire.The packaging looks very beautiful and won’t be damaged during shipment

Contact information

Web:www.brewingbest.com

Tel/Whatsapp:+86 15866015593

Email:[email protected]