Description

1500L craft stainless steel customized brewhouse equipment

| The brewhouse is both the heart and engine of the brewery where several critical processes in the creation of craft beer is performed. Brewhouses, along with other key pieces of brewing equipment, vary in capacity, features, and complexity, but all brewhouses share the need to wet grain, separate the wort from the grain, and boil the wort with a heating source. The three most common brewhouse heating methods are: steam, direct fire, electric. |

| 2-vessel brewhouse | 2-vessel brewhouse configuration offer brewers a simple and cost effective solution. Through combining mash tun & lauter tun, and kettle & whirlpool into a 2-vessel solution, it will help you on space and cost saving without compromising brewing quality and control. |

| 3-vessel brewhouse | 3-vessel brewhouse configurations offer brewers a more efficient and faster brewing solution and achieve multi temp. control for step mash. It can be comprised by mash/lauter, kettle/whirlpool, and hot water tank. |

| 4-vessel brewhouse | 4-vessel brewhouse configuration offer brewers a professional and higher performance brewing solution for multi batches brew per day. It is comprised by mash, lauter, kettle, whirlpool. DG’s 4-vessel brewing system offer you options of semi-auto or automation controlling and overall flexibility. |

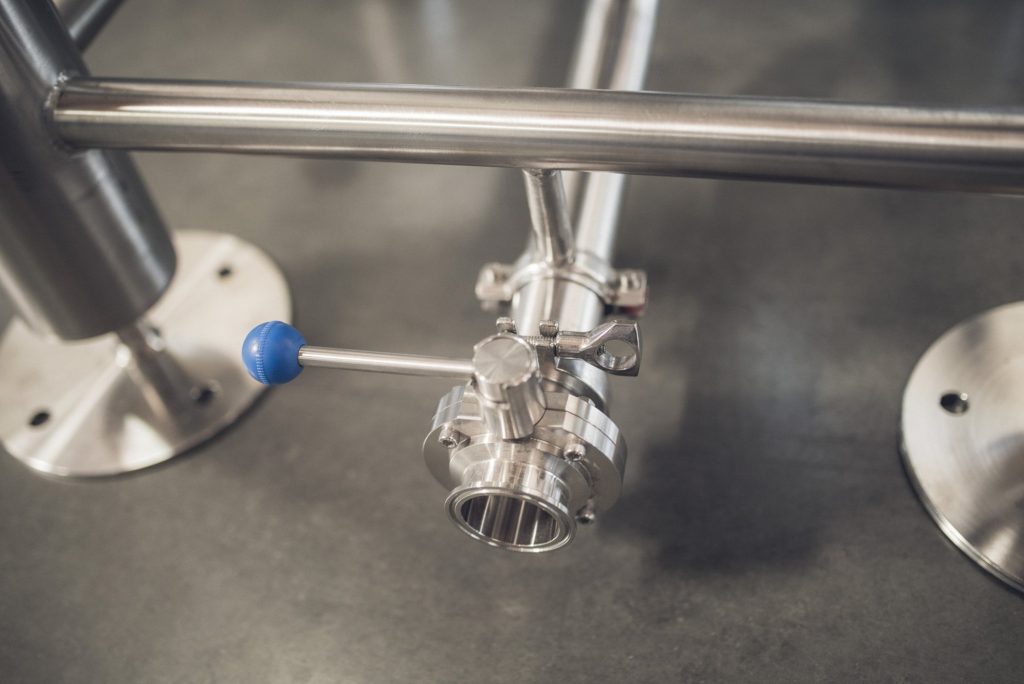

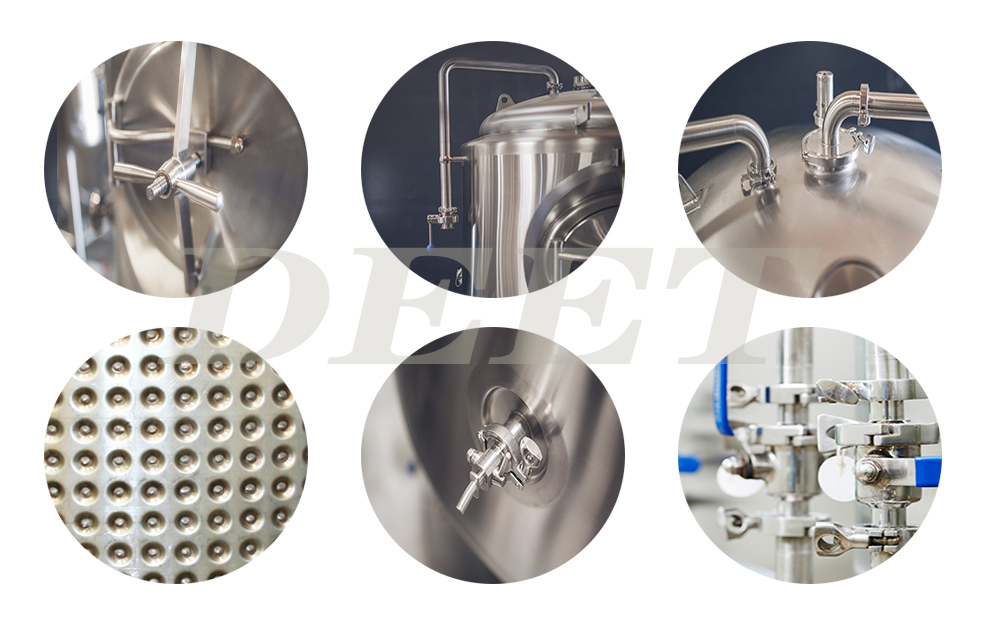

Detailed drarwing brewhouse equipment |

Why choose us |

Reliable performance: By providing turnkey solutions for compact and industrial-style craft breweries to customers’ specifications and future expansion with decent craftsmanship and reliable performance, we received high comments and repeated orders from our customers.

Good know-how: We have good know-how about design of a brewing system, plus keeping study about craft brewing. All the brewhouse are customized according to brewer’s craft and building limit.

Always stand by: We’re here to help 24/7. We’ll respond back to you by email or Whatsapp to get your questions answered as quickly as possible. Professional engineer will design the equipment as per your requirement. And we will visit States every year to provide after-sale follow up visit.

Guaranteed quality & certification: We own a excellent production team with superb professional skills for cutting, welding, polishing, testing etc. Every equipment will be tested strictly before delivery.

FAQ |

-

Can your brewing equipment make both lager and ale?

A: Yes, our beer brewing equipment can make both lager and ale.

-

How to achieve temperature control?

A: The PLC or digital displayer could control the temperature by connecting with the PT 100 sensor. The brewing tanks with rock wool to keep warm, the fermenters and bright beer tank with PU as cooling jacket to keep cool.

-

Is it possible to supply installation in our country?

A: Yes, we could supply our clients over sea service and direct the installation and brewing.

-

What type of control system?

A: Our control system is PLC control, also pass the CE.

-

What is kind of your packaging?

A: Export standard, wooden case, iron crate, or any suitable for long distance sea transportation.

Contact way