Description

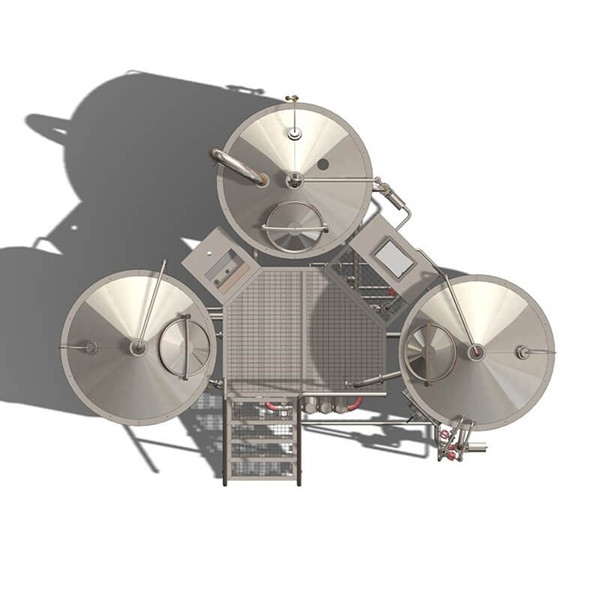

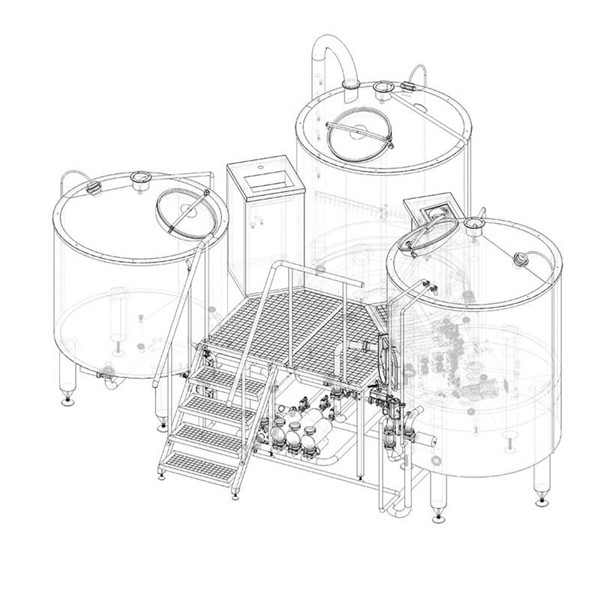

Beer brewing process:

1500L craft stainless steel industrial steam heating beer brewery equipment for sale

| Material:stainless steel 304

1.Inner thickness:3.0mm;outer thickness:2.0mm 2.Jacket thickness:1.5mm 3.Inner surface treatment:welds grinded to Ra 0.6um 4.Mirror surface finish inside. 5.Insulation: Polyurethane-thickness 100mm 6.Jacket pressure:design pressure:0.3Mpa;working pressure:0.12Mpa 7.360 degree omni bearing cleaning spray 8.Temperature way:double metal thermometer 9.Outsourcing surface:weld polish process |

Beer brewery equipment component details

| Beer brewery equipment | SUS304 | 1500L |

| Interior | SUS304 | Thickness 3mm |

| Exterior | SUS304 | Thickness 2mm |

| Bottom cone | 60 degree for fermentor | 150 degree for brewhouse |

| Heating/Cooling method | Steam heating/Glycol cooling | Dimple jacket |

| Temperature control | PT100 | |

| Pressure display | SUS304 | Pressure gauge |

| Pressure relie | SUS304 | Pressure relief valve |

| Cleaning | SUS304 | CIP arm with 360 spary cleaning ball |

| Insulation | Polyurethane | 100mm |

| Manway | SUS304 | Clamp or flange manway |

| Sampling valve | SUS 304 | Aseptic type, no dead coner |

| Dry hops adding port | SUS304 | Optional, clamp type |

| Carbonation device | SUS304 | Optional |

| Yeast adding tank | SUS304 | 30L |

| Bright beer tank | SUS304 | 100L/200L, single or double walled available |

Our service:

|

Design: DG engineers is providing various types of brewing design services according to cutomers’ requirements.

Testing and Maintenance: professional equipment and application product testing and maintenance services according to actuall working conditions.

Directed: transforms demand into the latest solutions and products with our advanced technology to help clients build core competitiveness.

Project Evaluation: this assessment includes all the elements of in mind project including advantage, technology, efficiency, quality control etc.

Continuous Service: actively provide pre-sales, sales, after-sales service and value-added services to help customers enhance value.

Training and Improvement: carries on the thorough training to the user, in order to maximize the equipment and the product functions.

If you are interested in our beer brewery equipment, please contact me.