Description

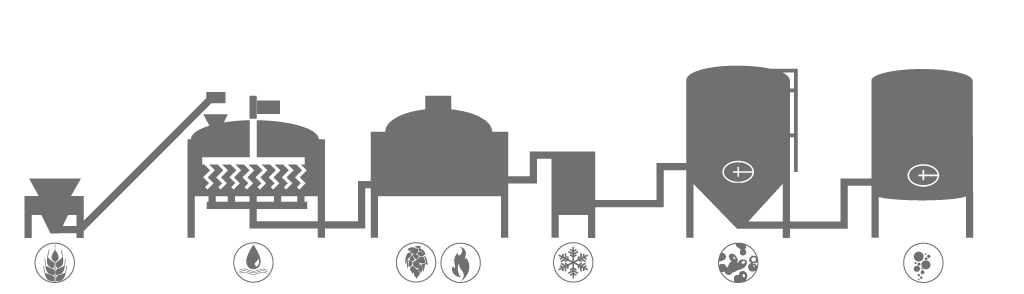

Beer brewing process |

| 1.Milling— Milling the grain is the first step to prepare for the mash.The goal of milling is to beak up the grain so the starches are exposed and to separate the husk from the grain.

2.Mashing—Once the grain is milled it is mixed with water in large tank known as mashing and its purpose is to convert the starches from the grain to fermentable sugars.The grain and water mixture sit for an hour at a temperature between 149F and 160F to give the enzymes time to fully convert the starches to sugars.Mashing at the lower end of this range results in a beer with less alcohol and more body,thus having a significant effect on the product. 3.Boiling—As the wort is collected into the boil kettle,it is heated until it comes to a boil.The boil usually lasts about an hour,sterilizes the wort,and cause proteins to gather and drop out.The boil is where hops and most other flavor additions are added to beer.Hops are a bitter tasting flower added to beer to help balance out the sweetness of the malt.They also add a floral or citrusy taste and aroma to the beer depending on the variety and time it is added at the beginning of the boil add bitterness to the beer.Hops added with 20 min remaining in the boil add the hoppy flavor to the beer.When hops are added at the end of the boil they add an aroma to the beer. 4.Chilling—After boiling and chilled prior to transferring it to the fermenters,the wort whirlpooled and chilled.The whirlpool cause all of the hop matter and proteins,trub,to form a cone in the middle of the boil kettle.The wort passes through a heat exchanger to chill it down to temperature favored by the yeast.This temperature usually ranges from 60-75F depending on the yeast and style beer. 5.Fermenting—The beer then sits in the fermenter anywhere from a week to two weeks.Fermentation for most of our beers is done in about 3-5 days but it may take longer for the yeast to drop out the suspension depending on the yeast strain.As the beer finishes it will be cooled down to a temperature.Just above freezing in a process known as cold crashing.This helps the remaining yeast drop out. Once the beer is finished in the fermenter it will be moved to a brite tank. |

| Raw material for brewing beer |

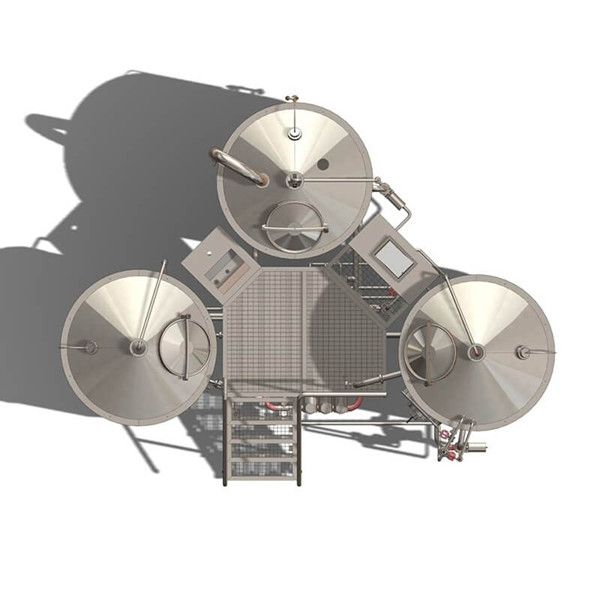

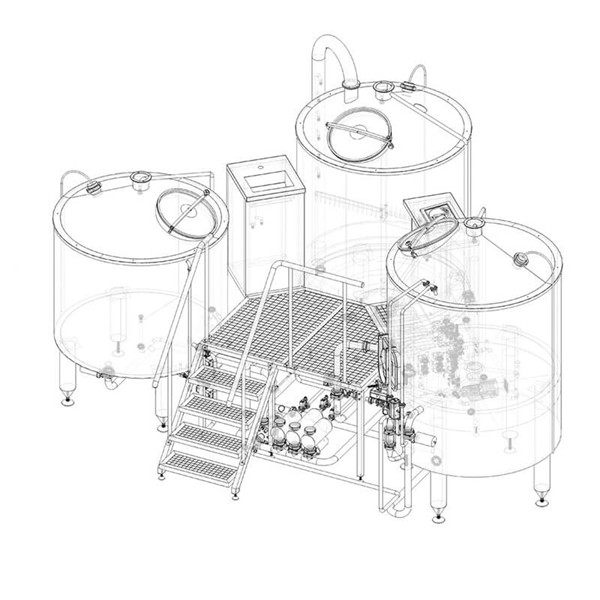

Brewhouse equipment classic configuration: |

| Mash Tun | Effective volume 1500L |

| Lauter | Effective volume 1500L |

| Boiling kettle & Whirlpool Tun | Effective volume 1500L |

| Hot water tank | 1000L |

| Wort pump | 3000L/h 1 Set |

| Double stage plate heat exchanger | area 5.1m2 |

| Control | Manual/Semi-auto/Auto |

| Copper Finish is optional |

General Technical Parameters: |

Brewhouse equipment

- Using 304 stainless steel material conform to standard.

- All material contact surface to be sanitary polished at Ra0.6μm.

- Construction with TIG welding.

- All pipe lines and vessels should pass tightness and pressure test before delivery.

- Nozzles, inlets, outlets and connections should be sealed before delivery.

- All medium connections are Tri Clamps.

- Electrical components are from CE certified manufacturers.

Company adcantages: |

| 1.Degong Equipment Technology Co., Ltd. specialize in designing, researching and manufacturing the brewery equipment, beer filling line and subsidiary equipment.

2.Our equipments have been CE ISO TUV UL certified. We are the only one who has got TUV certificate amongst all suppliers in north of China. 3.As a beer brewery equipment, craft beer brewing and brewhouse equipment manufacturer/ supplier from China, we offering high-cost performance beer brewery equipment and craft beer brewing for hotel, restaurant, beer pub and beer plant. 4.Introducing European advanced technology and innovating on the technology, DG equipment becomes the most professional supplier for liquid production and package turnkey project. |

| Contact information: |