Description

DEGONG equipment technology Co., Ltd. specializes in designing, researching and manufacturing beer brewery equipment, beer bottling and canning line and the subsidiary equipment. Introducing European advanced technology and innovating on the technology, DG company becomes the leader in domestic beer industry and the most professional supplier for liquid production and package turnkey project.

4-vessel brewhouse equipment

(mash tun,lauter tun,kettle tank,whirlpool tank with hot liquor tank)

3-vessel brewhouse equipment

(mash/lauter tun,kettle tank,whirlpool tank with hot liquor tank)

Can be freely combined according to customer needs

2 vessel brewhouse equipment

(mash/lauter tank and boiling/whirlpool tank )

Can be freely combined according to customer needs

Hot liquor tank(optional)

Brewhouse is various in combination of vessels, of course to achieve the same four steps mashing,lautering, boiling, whirlpool, by special brewing intentions of brewer including wort output, wort gravity,sparging water, brews in certain time, brewing method etc. Our company accepts special design for these variations.

Our brewhouse system separated to 2 vessels, 3 vessels, 4vessels and 5 vessels, capacity from 100L to 20000L, use electric or steam heat. Semi-automatic control and easy to operate.

| Brewhouse technical parameters: |

Mash Brew Kettle

Use – mashing, mixing and wort boiling.

Position – vertical

Appearance – Cylindric, top domed with conical inner bottom.

-Material body sus304

-Insulation- polyurethane 100 mm

-Cylindric and bottom milled steam heating – Max 3 bar pressure ensures 1°C/min heating speed.

-Complete pre-piped, pre-wired and test run prior to shipment.

Assembly:

-Top domed thermostatic hermetic closed glass manway door.

-Stainless steel mixer activated by 1.5 kw geardrive motor SIEMENS.

-Top domed lighted sight glass.

-Quick installed termo sensor PT100 connected to multi segments programmable controller

-Quick installed modular steam outlet condensator assembled with 0.5kw centrifugal water recycling pump for energy and water saving.

-Top domed cylindric hops grant for online hops insertion, adopted with wort circulation for effective mixing.

– Sanitary centrifugal 2.2 kw mash pump with VDF controller.

– Bottom mash inlet /outlet.

– Middle side wort/water inlet/outlet.

– Top dome wort /water inlet.

– Middle cone wort outlet.

– Quick installed Spray CIP balls X2 .

– Outlet/darainage connections –DN40

– Inlet connections –DN32

Raker and Upper manhole

Lauter tun

Use – lautering – separation of the solid part of mash (grains) from the liquid part (wort) during beer wort production process.

Position – vertical

Appearance – Cylindric, top domed with conic inner bottom connected to tube DN40 outlet collector connected to transflusient filtration grant.

Modular 4 parts screen sieve separating the wort bath from lautering area.

Sieve flutes width- 1 mm.

Sieve loading – 120-160 kg/ m2

-Material body and insulation cladding- sus304

-Insulation- polyurethane 100 mm

-Complete pre-piped, pre-wired and test run prior to shipment.

Assembly:

-Top domed thermostatic hermetic closed glass manway door.

-Stainless steel raker activated by 1.7kw geardrive motor SIEMENS.

-Top domed lighted sight glass.

-Quick installed termo sensor PT100 connected to controller for temperature measurement output.

– Rectangle sieve level placed hermetic closed manway door used for manual grains draining and sanitation operating.

– Sanitary centrifugal filtering 2.2 kw pump SIEMENS with VDF controller ensures controlled filtration and wort pellucid processes.

– Transflusient filtration cylindricwort grant contains: wort inlet with wort inspection valve, wort outlet, CIP ball for sanitation, gravity balancing valve for effective gravity and pump filtration.

-Wort sprinkling provided by sparging semicircle or spray balls.

-1BAR pressure release/vacumm valve placed on the dome for pressure discharging during aggressive sanitation process while the tank is hermetically closed for operation personal safety.

– Bottom wort outlet.

– Middle side wort/grains outlet for decoction process (if needed) and water inlet for stuck lautering preventing.

– Top dome wort /water inlet.

– Quick installed Spray CIP balls X2

-Lautertun piping connections are assembled for providing both gravity and pumping filtration, continuous and batch sparging.

– Outlet/drainage connections –DN40

– Inlet connections –DN32

Filter plate and spent grains outlet

Whirpool HLT Combination vessel

Use – wortwhirpooling, hot water preparation.

Position – vertical

Appearance – Cylindric, top domed with conical inner bottom.

-Material body and insulation cladding- sus304

-Insulation- polyurethane 100 mm

-Cylindric and bottom milled steam heating – Max 3 bar pressure ensures 1°C/min heating speed.

-Complete pre-piped, pre-wired and test run prior to shipment.

Assembly:

-Top domed thermostatic hermetic closedglassmanway door.

-Top domed lighted sight glass.

-Sanitary food grade thermo resistant silicone level gauge.

-1 bar pressure release/vacumm valve placed on the dome for pressure discharging during aggressive sanitation process while the tank is hermetically closed for operation personal safety.

-Quick installed termo sensor PT100 connected to multi segments programmable controller

– Bottom cone inlet /outlet.

– Middle cone clear wort outlet.

– Middle side wort/water inlet/outlet.

– Top dome wort /water inlet.

– Quick installed Spray CIP balls X2 .

– Outlet/darainage connections –DN40

– Inlet connections –DN32

brewhouse equipment details

| More information about DGET |

See our staff are sending the equipment to the container to prepare for delivery.

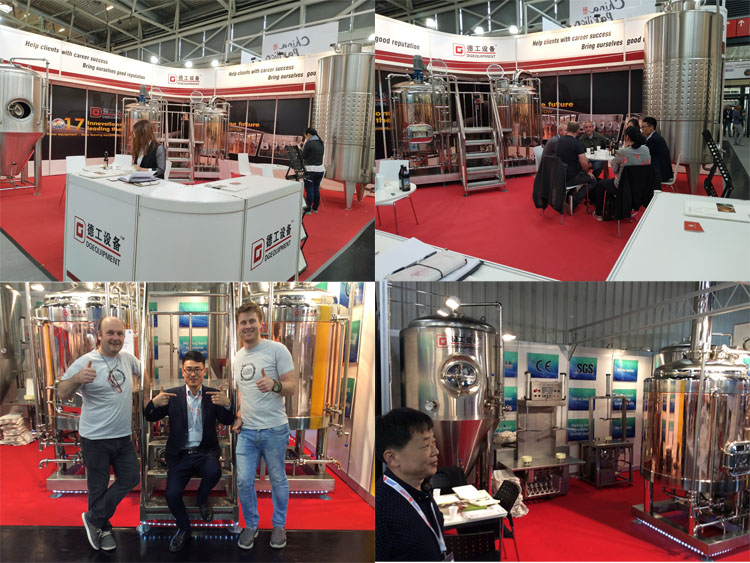

At the exhibition, we treated our customers with enthusiasm and fullness, and won unanimous praise.

Compared to other peers, we have the following advantages (but not limited to this)

1. TurnKey brewery Project with high level technology.

2. Custom made for any size.

3. International standard stainless steel 304,316 and red copper material.

4. Seamless Welding&8 times Inner polishing.

5. Advanced produce equipment.

6. Leading manufacturer of craft brewing equipment in China.

Contact me

Looking to expand, or get into beer brewery equipment business? Then check out us.