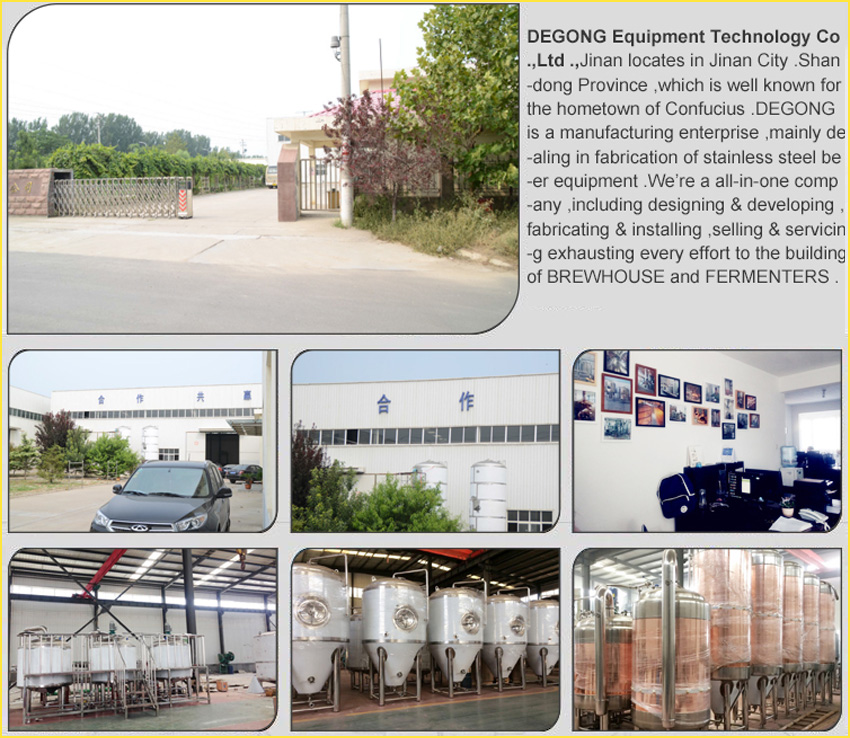

Description

The set of 2000L commercial beer brewery equipment is custom-built to fit each brewer’s individual needs. Our staff works with you on everything from defining your optimal brewery layout, to designing the setup and size of your brewhouse and tanks. Most importantly, every brewhouse is built with 304 Stainless Steel and uses Siemens or ABB motors, so they are as durable and hard-working as you are. Further, every equipment goes through a comprehensive quality control inspection before it leaves our factory, where everything, including the inside of the piping, is inspected. We more consider the better human-machine interaction and operability of our equipments. We design for success and work for glory!

2000L commercial beer brewery equipment

Brewhouse:

- Model: 2000L commercial beer brewery equipment

- Structure: 3-vessel steam heated beer brewhouse

- Material: Stainless steel

- 304 SS TIG weld construction

- Multi-pass plate heating exchanger

- With Glass grant

- Interior mirror polishing & 2B finish exterior surface

- Design pressure: 3.0 bar Working pressure: 1.5-2 bar

- Steel manhole(Glass manhole optional)

- Platform as optional

- ABB sanitary wort pump(variable frequency pump)

- With 360 coverage spraying ball attached at the top

- With flow meter installed on the hard connecting pipes

Fermenter:

- 304 SS TIG weld construction

- Operating pressure rated at 1.5-2 bar

- Reinforced stainless steel legs with adjustable height for leveling

- Side and bottom cooling jackets

- Tri-clover sanitary fittings

- Sample valve

- Pressure/vacuum relief valve

- Temperature gauge

- RTD sensor

- Side man way door (top manway optional)

- CIP arm and rotating spray ball 360° of coverage

- Gas arm with mechanical regulation valve

- Lifting Lugs

- Butterfly valves included

- Optional racking arm available with DIN, or tri-clover fitting

- This set of equipment is for micro brewery, especially for pub, restaurant, hotel, etc…

- Novel structure and attractive appearance

- More competitive price and better quality

- CE, ISO, TUV approved equipment

- More humanized design which allow you to operate easily

- Compact design saving your space

- All the materials touching the beer directly are all top quality food grade stainless steel.

- We use the first rate valves and manholes for all our equipments.

- I am here to guarantee all our customers that the materials are nonmagnetic.

- The thickness of the material exactly fit in with what showed in the specification sheet.

- If you are a new comer to the beer making field, Don’t worry, I will give you our professional recommendations. And the equipment must be top quality engineered.

- Engineer is always available to make the relative 2D and 3D drawings for you for your reference.

If you have interest,please get in touch with me freely.