Description

Full high quality stainless steel fermentation tank manufacturer,wrapper with 2mm high quality stainless steel, the middle medium high-performance polyurethane insulation,according to user’s requirements various specifications of the product design and manufacturing.

What is the beer fermenting tank?

Fermentation tank

- The inner of the fermentation tank are adopted good quality stainless steel.Use polyurethane to keep warm.The outside scarfskin is according to the customer’s requirement.You can choose stainless steel ,carbon steel and so on.

- Adopt the international standard of fermentation technology,on line database inspection and monitoring technology. The inner surface of tank is mirror-polished.The standard is ≤0.6μm.Completely meet the demand of sterilize system.

- The cooling jacket can achieve all countries’ standard,supply Miller.Meet cooling technology of coolant and pressure.

Stainless steel fermentation tank Technical Parameter

- Material:Inner(SUS304),thickness:3.0mm,Jacket(SUS)304,thickness:1.5mm

- Outer (SUS304),thickness:3.0mm

- Inner surface treatment:welds grinded to 0.6μm。

- Insulation:Polyurethane-thickness 100mm

- Temperature way:Double matal thermometer

- Outsourcing surface:Weld polishing processing

- Control method:temperature control, voltage control ang hand automatic control

CIP 360 degrees Omni bearing cleaning

Stainless steel fermentation tank details

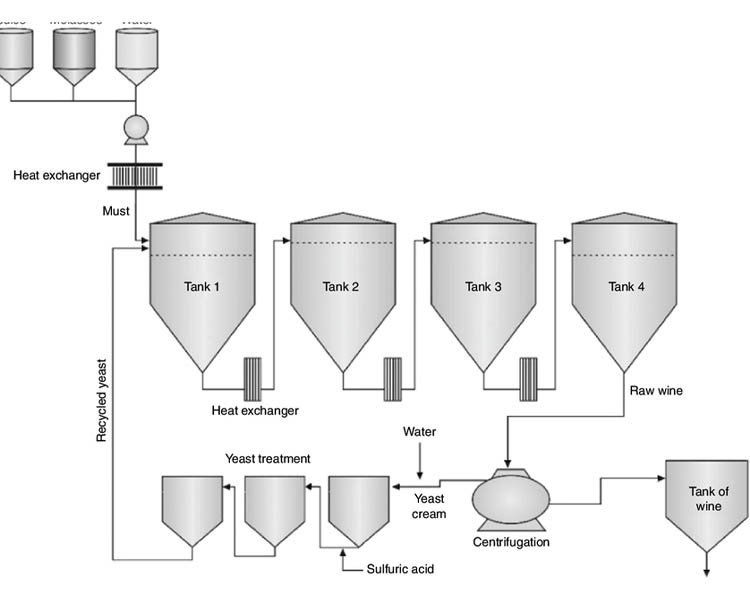

Stainless steel fermentation tank process

Once the wort stops rotating the cooling process is intiated. the wort is cooled to 5…18℃. This temperature provides the yeast with the optimal conditions for growth.the cold wort is pumped through a hose from the heat exchanger to the fermentation tank via brew house pump. The wort ferments in the fermentation tank. The yeast is racked. once the primary fermentation is completed, the green beer is pumped via a transpoetable pump from the fermentation tank to the serving tank.

Our advantages

DEGONG’s own factory has the advantages of customization, fine workmanship, durable equipment, beautiful appearance, price concessions, simple operation, corrosion resistance and technical support.

Our certificate

Our equipment is coming with certifications of PED and our company is TUV approved. We use CE approved components for customers. The quality, specification and function all meet the treaty of contract.

Our service

We can provide engineers to help you install the equipment, and we can also provide winemakers to help you solve technical problems。

with our customers

Packing & Delivery

Standard packing:

1.Cord ,film membrane

2.Firm membrane, wood box for free fumigation

Transport: by sea

Delivery :

1.We put your order into our tight production schedule to ensure the punctual delivery time.

2.Production or inspection report before your order packed.

3.Shipping notice/ insurance to you as soon as your order is shipped.

Contact us

If you have needs for craft brewing equipment, please feel free to contact us,my pleasure.

Whatapp:+86 17860525597

EMAIL:[email protected]

Contact person:Kate