Description

| We manufacture and supply brewhouse sizes from 50L to 20000L based on customer’s demand. Our brewery equipment is turn-key and consist of mill system, mash system, fermentation system, cooling system, cleaning system (CIP), control system and accessories. With brewery equipment you are able to produce outstanding full-bodied beers. Beginners will find it easy to brew with this fairly automated equipment. |

| Grains | Grains form the foundation on which beer is built. They lend flavor, aroma, color and mouthfeel to beer. They also provide the raw ingredients needed for the yeast to create alcohol. Quite simply, without grain, there is no beer. |

| Hops | While grains form the backbone of all beers, if left unchecked, they can cause a beer to become undrinkably sweet. That is why brewers add other ingredients, usually something bitter, to counterbalance the malt.Hops are the main source of bitterness in beer. |

| Water | Many people completely forget about water when listing the components of beer, even though it usually represents over 95% of the final product! More than a simple vehicle for holding the other ingredients, water lends many essential, if overlooked, characteristics to beer. |

| Yeast | Once introduced into unfermented beer (wort), yeast will immediately begin to consume the sugars from the malt. Yeast convert this sugar to alcohol, with an added byproduct being carbonation. To put it more crudely, yeast eat sugar, pee alcohol and fart carbonation! |

- Design pressure 0.3Mpa ;working pressure:0.12-0.15Mpa

- 4 stainless steel legs

- Interior shell: 304 stainless steel, thickness:3mm

- Exterior shell: 304 stainless steel, thickness:2mm

- Interior and exterior finish bright polish to 0.6um

- Side manway and 60 degree cone bottom

- Racking port and discharge port with butterfly valve and fittings

- Polyurethane insulation thickness 100mm for cooling jacket on side and bottom

- Fully welded exterior shell. CIP arm and spray ball and rotating tank racking arm included

Our factory |

|

Certification |

|

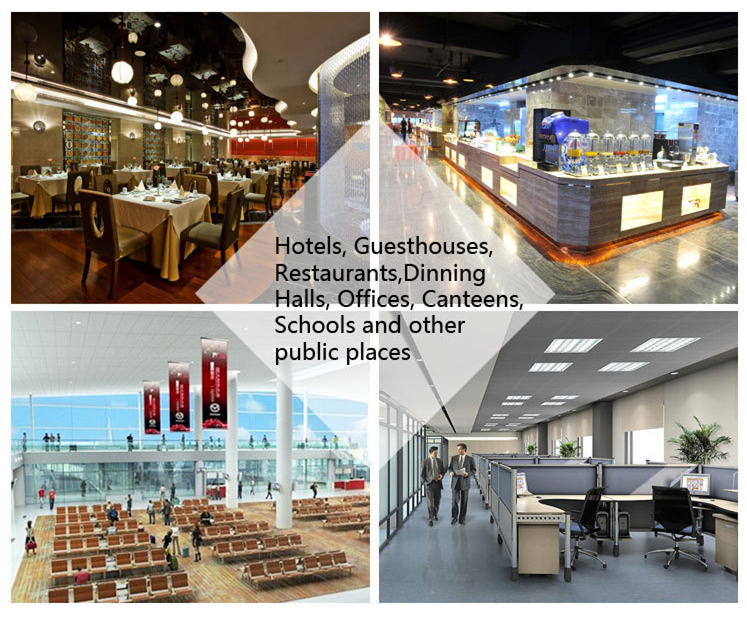

Application |

|

| DG is a professional manufacturer of craft beer equipment. Our company has integrated design, research, development, production, sales, installation, commissioning, and after-sales service, is committed to become the world first-class craft beer equipment supplier. |

| Company advantges |

| We adhere, with the company’s good management, the ideas of advance decision making, moderate operation, prudent management, sustainable development, and abide by the core values of being realistic, to create and to share. We do our best to provide our customers with added service.

Our equipments have been CE ISO TUV UL certified. We are the only one who has got TUV certificate amongst all suppliers in north of China. As a beer brewery equipment, craft beer brewing and brewhouse manufacturer/ supplier from China, we offering high-cost performance beer brewery equipment and craft beer brewing for hotel, restaurant, beer pub and beer plant. We design and build complete turnkey industrial-style craft breweries to your specifications and future expansion. Breweries’ reliable performance is guaranteed with our deep experience of big breweries and proven brewing technology in various big and small breweries around the world. |

If you are interested in our beer brewing equipment,please feel free to contact me.