Description

Degong provided the 1BBL-20BBL beer brewing equipment with high standard for customers.Our Industrial beer brewing equipment is turnkey and automated ,consisting of mill system, mash system, fermentation system, cooling system, cleaning system (CIP), control system and accessories.The brewery equipment can be used for commercial used or industrial brewery. With this high-quality brewery equipment, you are able to produce outstanding full-bodied beers.

Malt miller |

Particle adjustable rolling crusher

Flexible or steel auger for optional

Capacity:300-500kg/h

Doubel roller

Nosie: 45db or so

Mash system |

-

Mash/Lauter tun

-

Kettle/whirlpool tun

-

Steam heating method

-

hot water tank

-

Tubular glass level indicator

-

Tangential wort inlet

-

Side mounted grain outdoor with grain chute

-

Laser cutting V-wire False Bottom

-

Heating exchanger: 10 square meters

-

Wort pump: ABB motor, VFD control

-

Wort aeration device

-

Yeast adding tank: 30L

-

Seamless food grade stainless steel 304 pipes

-

Working platform

Technical parameters:

|

Design Volume : |

1bbl-10bbl |

Voltage: |

380V/220V or customized |

|

Power(W): |

15-70Kw depends on capacity |

Temperature way: |

Double metal thermometer |

|

Jacket Pressure: |

Design pressure 0.3 M Pa, working pressure <0.2 M Pa |

Certification:

|

CE ,ISO,TUV

|

|

Inner surface treatment: |

welds grind to Ra 0.6µm. |

Outsourcing surface |

Weld polishing processing

|

|

Equipment Material: |

SUS304 or Red Copper M2 for outer shell |

Thickness of Tanks: |

3mm for inner container/2mm for outer shell |

|

Insulation |

Polyurethane Insulation |

Insulation thickness: |

100 mm |

|

Color Available: |

Mirror SUS, Luxury red copper |

Heating: |

Electric/steam/direct fire heating |

Fermentation system |

Degong’s fermentation tank is certified with ISO,CE and TUV,featuring high quality and being applied in beer bar,restaurant, beverage factory in more than 50 countries all over the world. It will be the best choice for the buyer who want establish the commercial and industrial brewery for brewing the unique taste of beer. The fermentation system is consisted of fermenter, bright beer tank, yeast tank and other accessories under the technical view.

Technical parameters:

| Material (SUS304) thickness | Inner thickness: 3.0mm; Outer thickness: 2.0mm;External-Jacket thickness: 1.5mm |

| Interior Finish | Sanitary 2B finish, Pickled and Passivity; (8K Mirror finish optional) |

| Exterior Finish | Oil brushed finish (2B, 8K Mirror finish optional) |

| Inner treatment | Interior full polished to 0.2~0.4 μm without dead corner |

| Insulation | Insulated with high density Polyurethane foam 100mm |

| Cooling method | Glycol Jacket |

|

Vessel Pressure |

practical pressure:1.5 bar;design pressure:3.0 bar |

| Equipment with | cone 60°resist compression design,dripping |

Cooling system |

Cooling system is always consisted of circulation pump, glycol water tank and chiller. The glycol water tank is for filling the glycol water and the chiller is for generating the cooling capacity to reduce the temperature of the glycol water heated by heat generated by fermentation process.

-

chiller

-

Refrigerant: Freon R404A, Copeland compressor

-

glycol water tank

-

Glycol water circulation pump, VFD control

-

PPR pipe

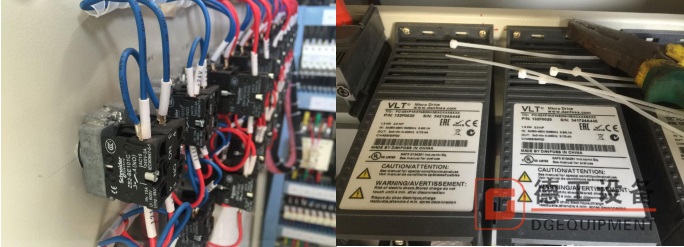

Control system |

Control system is the soul of a whole set of brewery equipment. It controls the running of each components such as pump, motor and whole brewery system.

-

Semi automatic control system or PLC fully automatic control system if requested

-

Siemens/Schneider/Omron components

-

PC or mobile remote control if requested

-

Individual control system for brewhouse system and fermentation system

Our Advantage |

Quality

Quality is the soil of an enterprise. We can offer you competitive advantage products.With us,your money in safe and your business in safe.

Delivery

Time is vital for both of us,so we have professional team work and production line to make sure the delivery in time.

Certificate

Our equipment is coming with certifications of PED and our company is TUV approved. We use CE approved components for customers. The quality, specification and function all meet the treaty of contract.

Packing&delivery |

Standard packing:

-

Cord ,film membrane

-

Firm membrane, wood box for free fumigation

Delivery :

– We put your order into our tight production schedule to ensure the punctual delivery time.

– Production or inspection report before your order packed.

– Shipping notice/ insurance to you as soon as your order is shipped.

Contact us |

Every beer brewing equipment is unique and requires different specifications. Please shoot us an email or give us a call for a quote.