Description

| Brewery description |

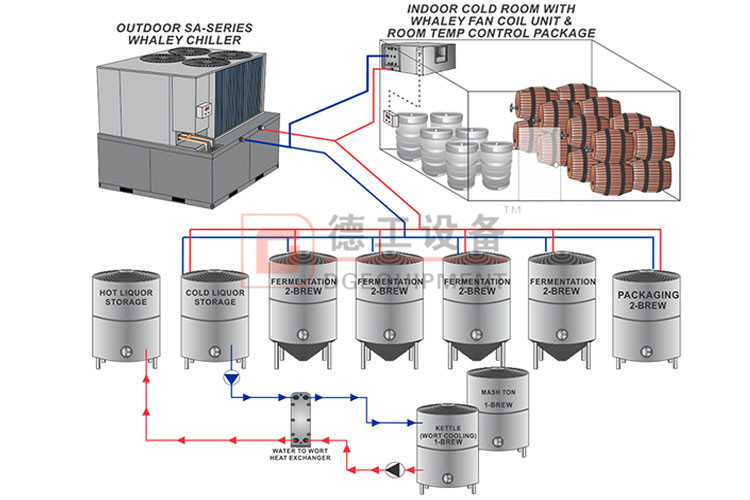

The Mash Tun is a key component of a brewhouse and is where grain, previously cracked in the grain mill, is combined with some hot water to convert complex starches into more readily-fermentable simple sugars. The mash tun may stand alone or be combined with a lauter tun to create a mash tun/lauter tun combination.

The Lauter Tun is a key component of a brewhouse and is used to recirculate wort over a grain bed in a clarifying process called “vorlauf”. Sugars are rinsed and extracted from the grain during the sparge cycle within the lauter tun. Wort being transferred to the brew kettle is lastly separated from grain, generally using a false bottom filter screen in the lauter tun.

Of course, you can also choose this configuration:Mash/lauter tun combination:

Combining the mash tun and lauter tun functionality into a single tank unit increases your efficiency and reduces your brewing equipment costs.

How to select a turnkey brewery equipment

Brew Kettle, a key component of any brewhouse, are where wort is boiled and reduced for approximately 60 to 90 minutes. During boil, initial hop additions are introduced into the brewing process. After boil is complete the wort is whirlpooled to separate unwanted solids from the desired liquid. It is generally recommended that brew kettles be made of stainless steel. In addition, brew kettles should be over-sized at a minimum of 30% to reduce the risk of boil-over.

The whirlpool is a key components of any brewhouse and are where boiled wort is precisely swirled to precipitate solids to accumulate them in a neat cone called a trub pile. Whirlpooling is the final brewing process before the wort is cooled in a wort chiller and yeast is pitched, initiating fermentation within a fermenter. Benefits of brewery whirlpools include clearer wort, faster cooling, increased hop aroma and flavor.

Hops are added during boiling to give the wort its aroma –breweryequipment

Fermentation tanks, or more commonly fermenters, are key components in beer brewing. Fermenters are specialized tanks designed to precisely control temperature and maintain the optimal conditions for fermentation, which occurs once the wort has been transferred from the brewhouse to the fermenter; a conical-bottom design is highly recommended for fermenters allowing for easier yeast harvesting.

As with all our brewing equipment, our fermenters are designed and manufactured to exacting standards:

Fermenters/ Fermentation tanks

Capacities available include:

BBL: 1-60barrelsHL: 1-60HL

Other capacities available upon request

100% food-grade 304 and 316 stainless steel, 3mm inner tank steel and 2mm shell materials

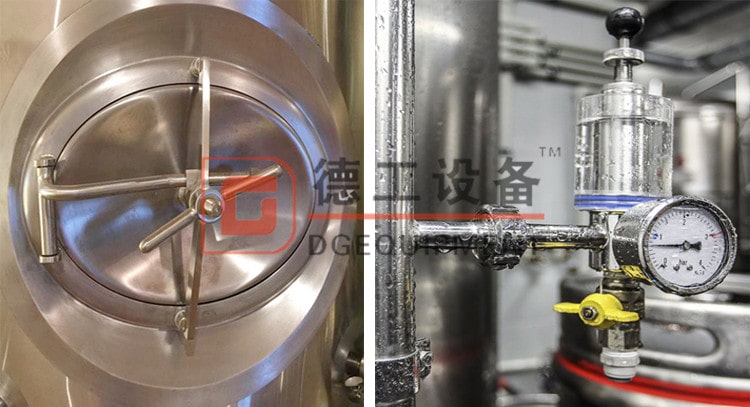

All fermenters are rated to 1.5 bar operating pressure

Two-zone glycol jacketing encompasses the 60-degree conical cone and sidewalls

Top-mount manway (optional side-mount configurations available)

Complete thermal insulation of side walls and cones(polyurethane)

All welds are blended and finished to a sanitary food-grade finish

Chiller for cooling fermentation tanks–brewery equipment

Every fermenter is equipped with:

Racking arm

Pressure relief valve

Blow-off/ clean-in-place (CIP) tube

CIP spray ball

Sample valve

Butterfly valves

TC clamps, gaskets and clamps

Optional rupture disc assemblies available

Side-mount manway and pressure gauge on the fermenters–brewery equipment

Loading tanks–brewery equipment

| Contact information |

If you’d like to get in touch, please drop us a line at [email protected]