Description

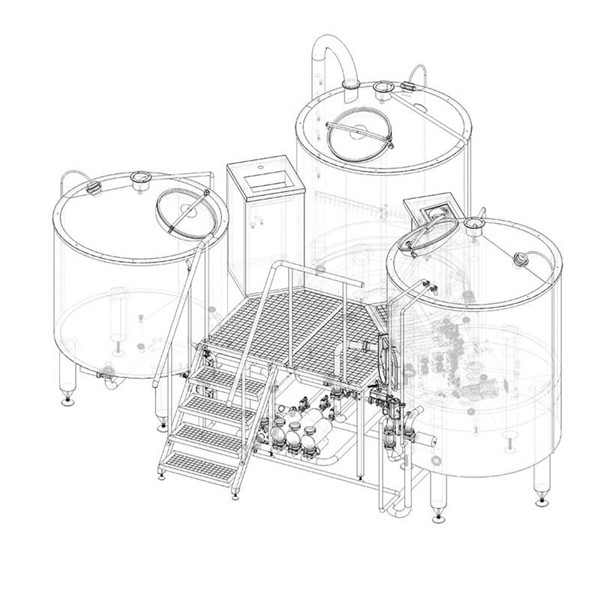

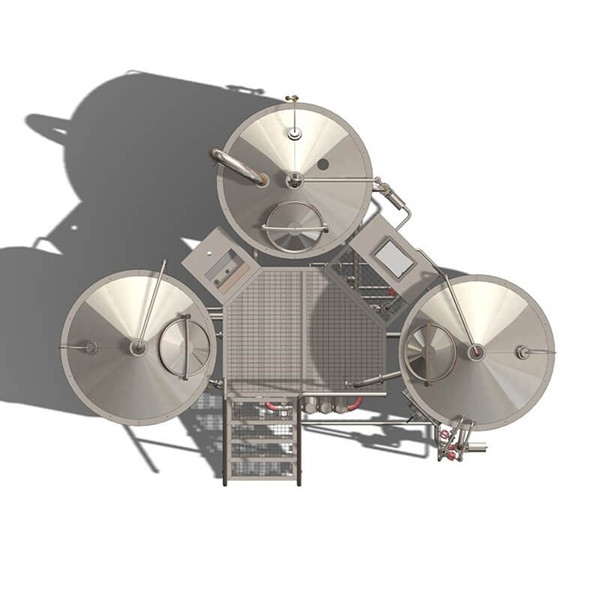

2000L commercial stainless steel craft brewing system for sale

Features:

- Mash vessel – grist hydrator, agitator, frequency drive

- Lauter tun – false bottom, rake system, sparging

- Wort kettle/whirlpool tun- steam jacket heating, tangential entry

- Pumps with ABB motor

- Wort grant, hops back

- Pipelines and valves

- Stainless steel 304 working platform

- Plate heat exchanger – 304 or 316 plates

- 20HL and 40HL fermentation tanks/bright beer tanks

- 40HL HLT and CLT

- Glycol cooling system(glycol chiller, glycol tank, glycol pump)

- CIP system

- Grain milling system(grain miller, flex auger, grist case)

- Keg washer/filler

Complete engineering support and onsite installation!

Technical parameters(Craft brewing systems)

| Beer brewing equipment | SUS304 | 2000L |

| Interior | SUS304 | Thickness 3mm |

| Exterior | SUS304 | Thickness 2mm |

| Bottom cone | 60 degree for fermentor | 150 degree for brewhouse |

| Heating/Cooling method | Steam heating/Glycol cooling | Dimple jacket |

| Temperature control | PT100 | |

| Pressure display | SUS304 | Pressure gauge |

| Pressure relie | SUS304 | Pressure relief valve |

| Cleaning | SUS304 | CIP arm with 360 spary cleaning ball |

| Insulation layer | Polyurethane | 100mm |

| Manway | SUS304 | Clamp or flange manway |

| Sampling valve | SUS 304 | Aseptic type, no dead coner |

| Dry hops adding port | SUS304 | Optional, clamp type |

| Carbonation device | SUS304 | Optional |

| Yeast adding tank | SUS304 | 50L |

| Bright beer tank | SUS304 | 1000L/2000L, single or double walled available |

Main Features

1) Capacity: 100 liter to 100000 liter as requirement.

2) Material: stainless steel 304/316 or red copper, as requirement.

3) General configuration: mill, brew house, fermentation, cooling and cleaning etc.

4) Heating principle: electric heating, steam heating, gas fire etc.

5) Electricity voltage/frequency can be customized.

Company advantages:

Degong Equipment Technology Co., Ltd. specialize in designing, researching and manufacturing the brewery equipment, beer filling line and subsidiary equipment.

Our equipments have been CE ISO TUV UL certified. We are the only one who has got TUV certificate amongst all suppliers in north of China.

As a beer brewery equipment, craft beer brewing and brewhouse manufacturer/ supplier from China, we offering high-cost performance beer brewery equipment and craft beer brewing for hotel, restaurant, beer pub and beer plant.

Introducing European advanced technology and innovating on the technology, DG equipment becomes the most professional supplier for liquid production and package turnkey project.

Contact information