Description

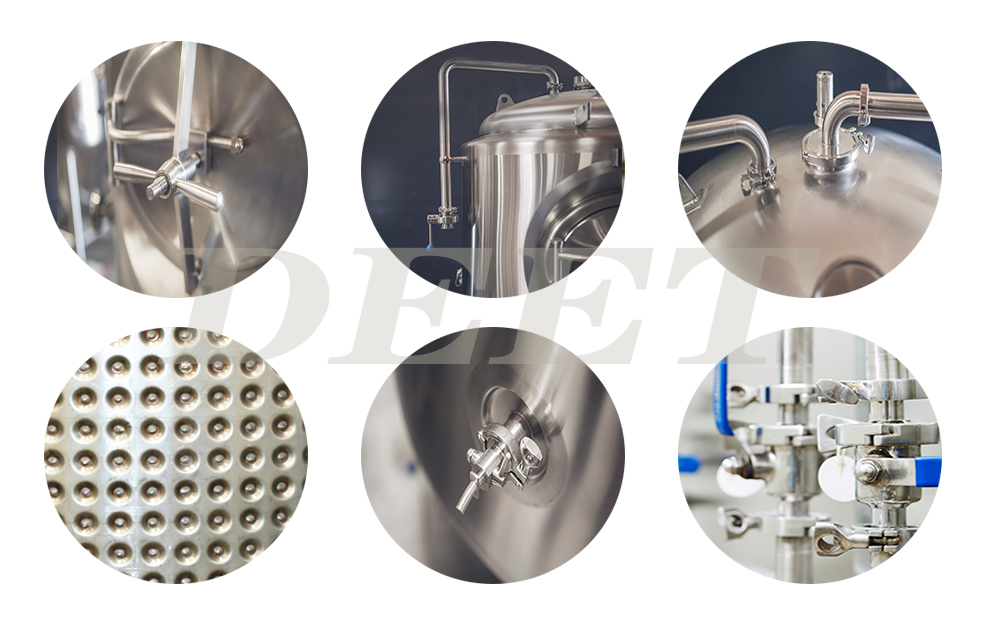

This 2000l beer fermentation tank features two-zone glycol jacketing that will allow you to precisely control fermentation temperature. Designed for precision and brewing excellence, this 2000l beer fermentation tank also features a side manway for more effective cleaning via CIP.

2000l Commercial used stainless steel glycol jacket beer fermentation tank/vessel

| Dimensions | We can provide normal dimension if customer dont have special requirement.If have,we will

Design suitable dimension according to customer’s requirement. |

| Capacity | Nominal capacity plus 25% |

| Top Head | Dished head |

| Lifting Lugs | 2 lifting lugs |

| CIP | Removable CIP & fixed spray ball (180° up, 65mm) on 1½” TC with 1½” TC line down to

working height |

| Wall | Inner thickness 3mm;Outer thickness 2mm. |

| Bottom Cone | 60° cone angle, ”1½ knuckle radius to cone |

| Cooling Jacket | On sidewall and bottom cone – number of zones determined by tank size

Maximum 0.3MPA working pressure, 1” to 1½” FNPT inlet / outlet |

| Legs | 4pcs completely SUS304 heavy duty legs with leveling pad and legs support |

| Insulation | 100mm polyurathane |

| Manway | Top manway or side manway |

| Drain | 1½” TC butterfly valve c/w “J” pipe |

| Tank Material | All quality inspected 304 stainless steel alloy |

| Exterior Finish | 2B with all welds ribbon polished |

| Interior Finish | 2B with all welds TIG welded with heat stain removed |

| Tank Pressure | Maximum 0.3Mpa |

| All accessories on tank | •Full sanitary sampling valve

•1½” TC Vacuum Pressure relief valve on top head •Mechanical relief valve 2 bar on CIP arm •Shockproof pressure gauge on CIP arm •Dry hopping port with solid end cap •Thermowell for high accuracy temperature sensor •1½” Raking arm •carbonation stone •1½” TC RSL Sample valve |

Main Features of 2000L beer fermentation tank/vessel:

Inner Shell: 4mm, 304 Stainless Steel

Outer Shell: 2mm, 304 Stainless Steel

Inner shell design pressure 29PSI(2bar), testing pressure 29PSI(2bar), designed to suit all types of craft breweries.

Inner cooling jacket design pressure 29psi (2 bar).

25% headspace for fermenting process.

Minimum 3 inch Thermal Polyurethane Insulation with both cone and shell coolant jackets.

Chloride ion barrier paint on the out surface of the inner shell to prevent any potential corrosion to ensure longevity.

Tank inner side is polished within 0.6µm sanitary finish.

Tank outside is 2B stainless steel plate(optional brushed stainless, #4 finish).

Shell and bottom cone cooling jacket for better temperature control.

Pillow Plate on shell body and cone; Omega laser welded and inflated.

Hook outside on the shell for ladders.

Other customization possibly available upon request.

Main Components of 2000L beer fermentation tank/vessel:

Manhole on the top head (standard).

Level Indicator (standard) for inner tank.

Vacuum/Pressure combined valve. Tank top fittings, pressure gauge.

Pressure keeping valve with sight glass for controlling and monitoring fermenting process.

Built in rotary spray ball within the inner tank for cleaning.

Sanitary sampling valve, with the shortest connection on the tank, easily CIP cleanable.

Manual ball valve for easy glycol changing over thus temperature control.

Other customization possible upon request.

HEAT CONTROL: Our commercial grade stainless steel brewing systems for sale provide the ability to control heat from 0 to 100% (either in 1% increments on our Advanced panel, or infinitely adjustable with the dial on our basic panels.

SAFETY: We provide GFCI breakers that meet the NEC requirements for protection of human life on each element circuit for safety and better reliability in a wet brewery environment.

EASY TO CLEAN: Our systems have sanitary construction with food grade valves, sanitary welds and tri clamp fittings. Spend less time cleaning, and more time brewing delicious brew.

DURABILITY: Our brewing systems are engineered to commercial standards and are built to last.

WORT PROTECTION: Our Ultra-Low watt density elements, plus our ability to lower the element’s power (which makes the watt density proportionally lower with our 0-100% adjustment), there is no scorching or off flavors.

LOW COST TO VENT THE STEAM:With our stainless steel commercial grade brew kettles, you use a low cost condensate stack or steam condenser to vent the steam. Steam MUST be properly ventilated to avoid serious mold and potential health safety issues in your building.

If you have interest,please get in touch with me freely.