Description

2000L Isobaric Fermentation tank(Unitank),which is an indispensable part of brewing equipment. The quality of fermenter directly affects the taste of beer.The beer fermentation tank of DEGONG is in strict accordance with international standards and are suitable for many beer types, such as lager, ale, IPA, etc. We will decide to use one glycol zone or multiple glycol zone according to the size tank.Fermenting vessels will include all necessary spare parts, such as mechanical control valves, breathing valves, pressure gauges, etc….

2000L isobaric fermentation tank double wall insulated stainless steel unitank for sale

Fermentation tanks, or more commonly fermenters, are key components in beer brewing.2000L Isobaric fermentation tank are specialized tanks designed to precisely control temperature and maintain the optimal conditions for fermentation, which occurs once the wort has been transferred from the brewhouse to the fermenter; a conical-bottom design is highly recommended for fermenters allowing for easier yeast harvesting.

2000L Isobaric fermentation tank/fermenter/Unitank

Inner Shell: 3mm, 304 Stainless Steel

Outer Shell: 2mm,304 Stainless Steel

Inner shell design pressure 29PSI(2bar), testing pressure 29PSI(2bar), designed to suit all types of craft breweries.

Cooling jacket design pressure 29psi (2 bar).

25% headspace for fermenting process.

Minimum 3 inch Thermal Polyurethane Insulation with both cone and shell coolant jackets.

Chloride ion barrier paint on the out surface of the inner shell to prevent any potential corrosion to ensure longevity.

Tank inner side is polished within 0.6µm sanitary finish.

Tank outside is 2B stainless steel plate(optional brushed stainless, #4 finish).

Shell and bottom cone cooling jacket for better temperature control.

Pillow Plate on shell body and cone; Omega laser welded and inflated.

Hook outside on the shell for ladders.

Other customization possibly available upon request.

Food grade Stainless steel 304 butterfly valve

Carbonation stone

Side manhole

Sample valve

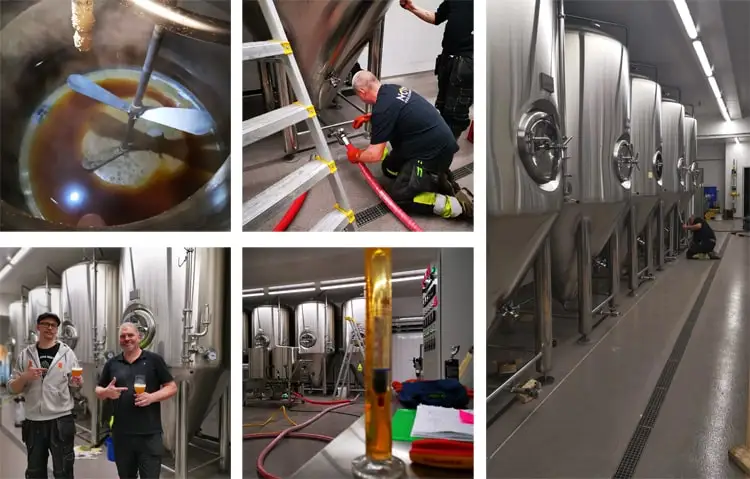

1000L copper beer brewery equipment in Sweden

1000L copper beer brewery equipment in Sweden

500L copper 2 vessels brewhouse show in a Irish brewpub

1000L stainless steel electric heating 3 vessels brewhouse in an Irish brewpub

Install equipment in Ireland,Italy

Engineer install equipment in Swenden

Guarantees:

1.All the materials touching with beer directly are all top quality food grade stainless steel

2.We use the first class valves and manhole for our equipments

3.All the materials I use is nonmagnetic.

4.The thickness of the material exact fit in with what shown in our quotation sheet

5.Most importantly,Our staff is always available for your needs and questions.

After-sale services:

1.Within the warranty period, any malfunctions caused by the quality issues or material issue, Degong will be responsible to it.

2.After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.

3.For the malfunctions beyond the warranty period, Degong will also be responsible to it, but the seller should take in charge of the expenses.

4.Degong can dispatch technicians to install the equipments for you, but the seller should take charge of the expenses