Description

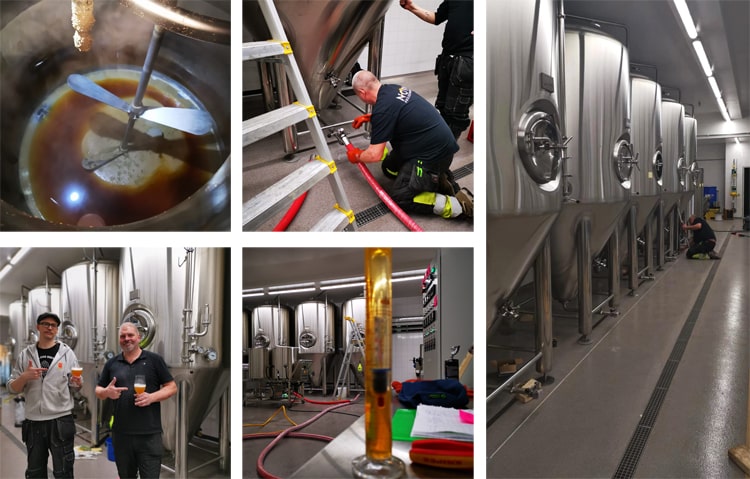

Carbonating a full batch of beer with a carbonating stone in a bright beer tank provides for much quicker carbonation. The carbonating stone increases the surface area contact with the beer by producing tiny bubbles of CO2, which are more easily absorbed into the beer.

2000L Bright beer tank/beer storage tank/beer service tank/BBT/brite tank

What is a bright beer tank

BBT Often called a bright beer tank,“brite” beer tank, serving tank or secondary tank, a bright beer tank is the vessel in which beer stay after primary fermentation and filtering, so it can further mature, clarify and carbonate, as well as be stored for kegging, bottling, canning and packaging.

Main features of bright beer tank

Outer Shell: 2mm,304 Stainless SteelInner Shell: 3mm, 304 Stainless Steel

Inner shell design pressure 29PSI(2bar), testing pressure 29PSI(2bar), designed to suit all types of craft breweries.

Inner cooling jacket design pressure 29psi (2 bar).

25% headspace

Minimum 3 inch Thermal Polyurethane Insulation with both cone and shell coolant jackets.

Chloride ion barrier paint on the out surface of the inner shell to prevent any potential corrosion to ensure longevity.

Tank inner side is polished within 0.6µm sanitary finish.

Tank outside is 2B stainless steel plate(optional brushed stainless, #4 finish).

Shell and bottom cone cooling jacket for better temperature control.

Pillow Plate on shell body and cone; Omega laser welded and inflated.

Hook outside on the shell for ladders.

Other customization possibly available upon request.

Main Components of bright beer tank

Level Indicator (standard) for inner tank.Manhole on the top head or side (standard).

Vacuum/Pressure combined valve. Tank top fittings, pressure gauge.

Pressure keeping valve with sight glass for controlling and monitoring fermenting process.

Built in rotary spray ball within the inner tank for cleaning.

Sanitary sampling valve, with the shortest connection on the tank, easily CIP cleanable.

Manual ball valve for easy glycol changing over thus temperature control.

Racking arm for beer out on the cone

Other customization possible upon request.(such as carbonation stone,hops adding hole or others)

thermometer&pressure gauge&mechinery regulating valve

Carbonation stone&sample valve

DIN VALVE

Certification

Delivery&Packing

The packing is wooden case or iron frame according to the LCL OR FCL,to asure the tanks will not be destroyed during shipment.

Service

After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.

Why choose us:

1.Always delivery in time

2.Guarantee is 3 years

3.Install equipment freely

4.Real food grade SUS 304

5.Promise good pre service and after service