Description

Carbonating a full batch of beer with a carbonating stone in a beer aging tank provides for much quicker carbonation. The carbonating stone increases the surface area contact with the beer by producing tiny bubbles of CO2, which are more easily absorbed into the beer.

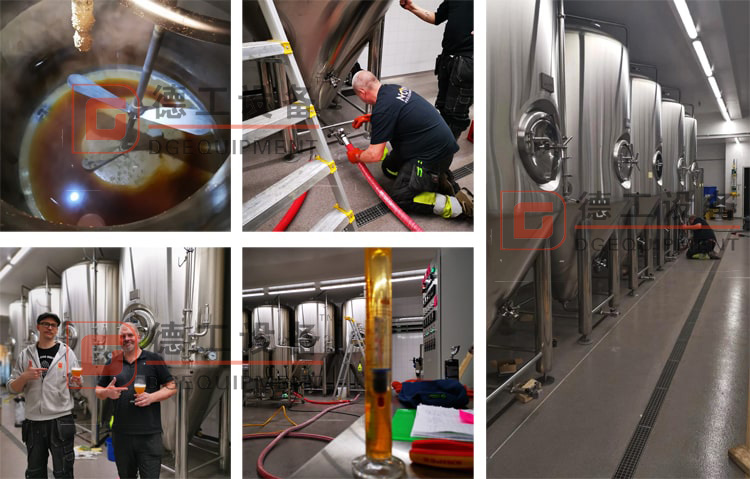

2000L Bright beer tank/beer storage tank/beer service tank/BBT/brite tank/beer aging tank

What is a beer aging tank

BBT Often called a “brite” beer tank, beer aging tank,serving tank or secondary tank, a beer aging tank is the vessel in which beer is placed after primary fermentation and filtering.This professional equipment is designed to storage, serving, carbonization, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their filling into kegs or bottles. The bright beer tank is available in several variants, it is made of food grade steel AISI 304.The tank is normally available in several versions (optional dimensions, quality class, maximum pressure).

Main features of beer aging tank

Inner Shell: 3mm, 304 Stainless Steel

Outer Shell: 2mm,304 Stainless Steel

Inner shell design pressure 29PSI(2bar), testing pressure 29PSI(2bar), designed to suit all types of craft breweries.

Inner cooling jacket design pressure 29psi (2 bar).

25% headspace

Minimum 3 inch Thermal Polyurethane Insulation with both cone and shell coolant jackets.

Chloride ion barrier paint on the out surface of the inner shell to prevent any potential corrosion to ensure longevity.

Tank inner side is polished Ra < 0.6 μm or less (grinded surfaces) / Ra < 0.4 μm or less (polished surfaces)

Tank outside is 2B stainless steel plate(optional brushed stainless, #4 finish).

Shell and bottom cone cooling jacket for better temperature control.

Pillow Plate on shell body and cone; Omega laser welded and inflated.

Hook outside on the shell for ladders.

Other customization possibly available upon request.

Outer jacket of the tank of stainless steel – Kind of the surface finishing (standard = grinded) choosed by customer.

Main Components of beer aging tank

Service door (manhole) – The door is positioned on the front arched part (SQ = opening inward / HQ = opening outward)

Bottom filling/emptying armature – The inlet / outlet pipe with a butterfly valve for filling tank, discharging of yeast and draining of full content of the tank

CIP ball – CIP sanitizing ball (SQ = statical / HQ = rotational) – one or more pcs according length of the tank

Sanitation pipe – A multifunction pipe with a ball valve for connection of a shower head to the cleaning-sanitizing CIP station , the adjustable pressure valve with manometer, CO2 inlet

Sample valve – cleanable and sanitizable sampling cock for collection product samples

Vacuum valve – Double-acting overpressure valve (standard = 3.2 bar) and underpressure

Pressure gauge – It is included in the set of the adjustable pressure valve. Made of stainless steel, with glycerine inside.

Stackable feet (support plates) – They allow the stacking of the tanks into space-saving assemblies in more horizontal layers.

Filling level indicator – Sanitizable glass or plastic pipe for visualisation height level of the beverage product in the tank (SQ = fixed / HQ = removable)

Certification

Delivery&Packing

The packing is wooden case or iron frame according to the LCL OR FCL,to asure the tanks will not be destroyed during shipment.

Service

After delivering the equipments to our customers, Degong will arrange special worker to do the track service,because we set up the marketing department for specially dealing with the feedback of customers for providing the satisfied service. Once Degong gets the feedback from customers, we will do our best to deal with it for you.

Why choose us:

1.Always delivery in time

2.Guarantee is 3 years

3.Install equipment freely

4.Real food grade SUS 304

5.Promise good pre service and after service