Description

| Beer brewing process | Malt is ground in the grain mill.

The milled grains are transported with bags to mash kettle. In the mash tun the grist is mixed with brewing water from hot water tank(to form the mash) In the lauter tun the dissolved liquid extract (wort) is separated from the solids (spent grains) Brewing kettle is used for boiling. Whirlpooling is creating by circulating the wort. The cold wort is pumped through a hose from the heat exchanger to the fermentation cellar via the brew house pump. The wort ferments in the fermentation tank. The green beer matures in the serving tank. After the ageing process the beer can be served directly from this tank. |

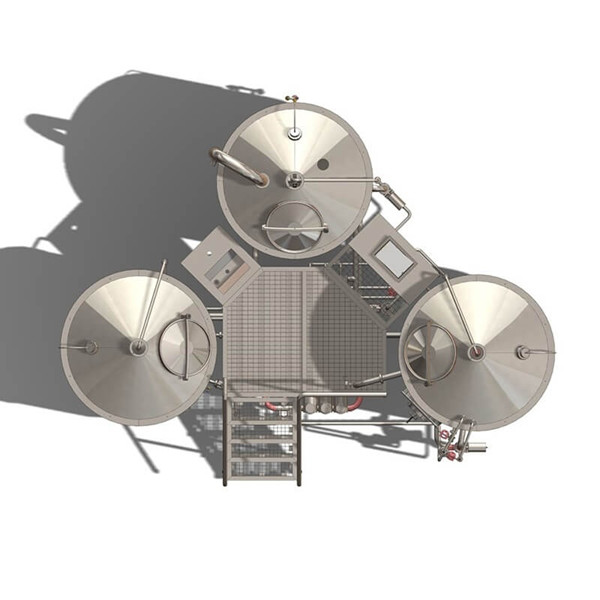

2000L stainkess steel beer brewing equipment for sale

| Part 1 | Malt grinder | 300KG/H | 2 Roller |

| Part 2 | Mash/boil tun | 2000L | With mechanical stirrer |

| Lauter tun | 2000L | Filtration bottom | |

| Whirlpool | 2000L | Separate vessel | |

| Hot water tank | 2000L | Connect to plate heat exchanger | |

| Plate heat exchanger | Hops filter in advance one/two grade exchanger | ||

| Pumps | frequency | ||

| Part 3 | Fermenter | 2000L | Follow drawing |

| BBT | 2000L | Follow drawing | |

| Yeast adding tank | |||

| Part 4 | Control cabinet | For fermentation system and cooling system | |

| Part 5 | Glycol water tank | 4000L | |

| Chiller | 30HP | ||

| Part 6 | CIP system | 300L | With pump and controler

moveable or not |

beer brewing equipment details

| Quality standard:1. Construction by high quality SUS 304 food grade stainless steel, all pipes are SUS 304. 2. All tanks will be tested and detected in the NDT room after finished, to ensure no leakage. 3. All jackets will do water and pressure testing, design pressure: 3bar, working pressure: 1.5-2bar; 4. All tanks will be pressure protection 48 hours before leaving from factory; 5. All the welds are TIG full welded, dimpled jacket by using water to weld to make sure uniform to be long life. 6. All tanks are mirror polishing inside without dead corner, welds grinded to Ra 0.6um. 7. All the manholes and clamps gaskets will be sanitary. The designer of brewing equipment for brewpub or restaurant must consider, · Aesthetic · Space Utilization · Safety · Easier Operation · Waste Water Treatment · Lower Cost |

Contact information