Description

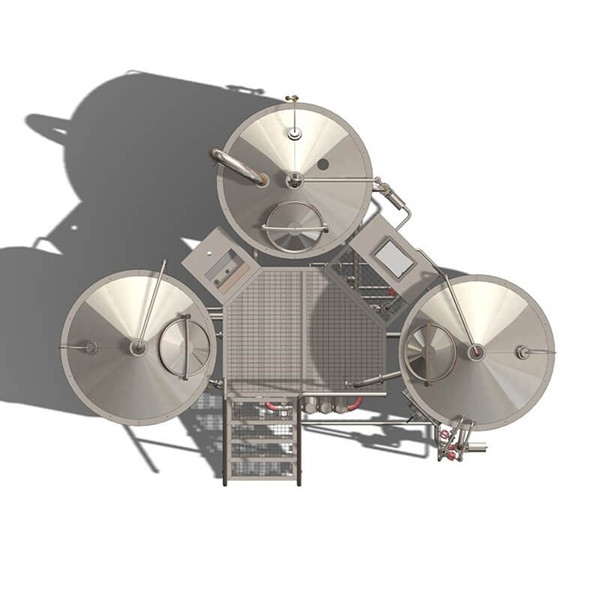

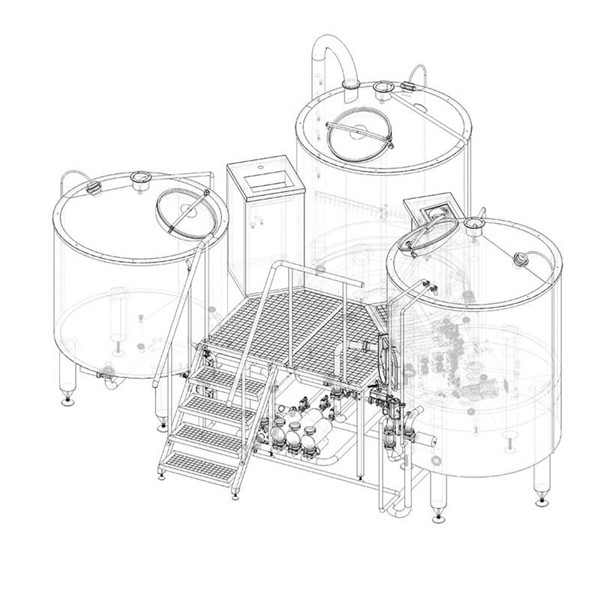

2000L stainless steel industrial large scale beer brewing equipment

For 2000L brewhouse,mash system includes mash/lauter tank,boiling/whirlpool tank and hot water tank.The heating method can be electric heating,steam heating and direct fire heating.In particular, steam is heated more evenly and more quickly.

| Effective volume:2000L | Total volume:2600L |

| Inner thickness:3mm | Outer thickness:2mm |

| Material:stainless steel | Design pressure:0.3Mpa |

| Insulation:polyurethane 100mm | Working pressure:0.12-0.15Mpa |

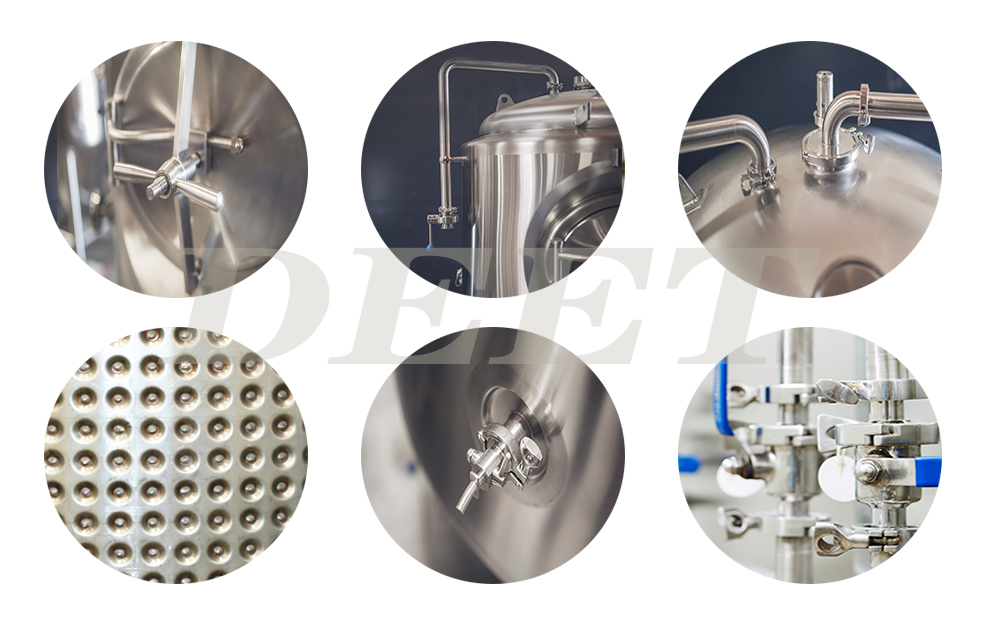

| The precision of polishing can up to Ra 0.6 µm | Interior:mirror polish |

| CIP 360 degree omni bearing cleaning | Temperature way:double metal thermometer |

Technical parameters:(large scale beer brewing equipment)

| Fermentation tank | Material:SUS 304

1.Inner thickness:3.0mm;outer thickness:2.0mm 2.Jacket thickness:1.5mm 3.Inner surface treatment:welds grinded to Ra 0.6um 4.Mirror surface finish inside. 5.Insulation: Polyurethane-thickness 100mm 6.cone 60 degree resist compression design,dripping 7.Heat exchange area: 5.1 m2 8.Vessel pressure:1.5 bar/3.0 bar |

| Yeast adding tank | Adopts sus 304 stainless steel fine polished process,outer stainless polishing.

Adding yeast sight glasses,aseptic air mouth,and wort pipe connection mouth. |

What a wonderful thing it is to have an enthusiastic colleague meet an enthusiastic client.This exhibition is also very successful, and we will participate in more such activities in the future to provide better equipment and services for customers from all over the world.

Our company&factory

We have CE&ISO certification, etc., which is praised by the industry for its high quality and excellent service level.

We are a reliable partner of professional brewing equipment.

FAQ

1. Can your brewing equipment make both lager and ale?

A: Yes, our beer brewing equipment can make both lager and ale.

2. How to achieve temperature control?

A: The PLC or digital displayer could control the temperature by connecting with the PT 100 sensor. The brewing tanks with rock wool to keep warm, the fermenters and bright beer tank with PU as cooling jacket to keep cool.

3. Is it possible to supply installation in our country?

A: Yes, we could supply our clients over sea service and direct the installation and brewing.

4. What type of control system?

A: Our control system is PLC control, also pass the CE.

5. What is kind of your packaging?

A: Export standard, wooden case, iron crate, or any suitable for long distance sea transportation.

Thank you for your visit. If you are interested in our equipment, please feel free to contact me.