Description

Craft microbrewery are divided into 100 liters, 150 liters, 200 liters, 300 liters, 500 liters, 1000 liters, 2000 liters and other different types of equipment. The device specifications are different and the configuration details are different.

The complete micro beer equipment mainly includes the main components such as crushing system, mashing system, fermentation system, refrigeration system, cleaning system, control system and many other auxiliary components.

The compact Brewhouse section consists of two universal apparatus: Mash-Lauter tun (M-L) and Kettle-Whirlpool tun (K-W). According to the operational convenience of the beer brewing process, the volume ratio of the mashing tank to the fermenter is often 1:1 or 1:2.

200L beer brewhouse of craft microbrewery equipment description

|

Other component of brewhouse

|

|

| Mash/lauter tank

1.Be made of food sanitary stainless steel 304 2. Inner surface treatment: welds grinded to Ra 0.4µm without dead corner. 3. 100% TIG welding with pure argon gas shield 4. Insulation: Polyurethane-thickness 80 mm. 5. Temperature way:Double metal thermometer 6. Grain washing round pipe; CIP rotary spray device 7. Thermo well for high accuracy temperature sensor 8. Sanitary liquid level indicator with valves 9. Stainless steel laser cutting False Bottom/Filter

|

Boiling/whirlpool tank

1.Be made of food sanitary stainless steel 304 2. Inner surface treatment: welds grinded to Ra 0.4µm without dead corner. 3. 100% TIG welding with pure argon gas shield 4. Insulation: Polyurethane-thickness 80 mm. 5. Temperature way:Double metal thermometer 6. CIP rotary spray device 7. Thermo well for high accuracy temperature sensor 8. Sanitary liquid level indicator with valves 9. Tangential port for whirlpool

|

200L/400L Fermentation tank of craft microbrewery equipment description

|

1. Stainless steel 304

2.Equipment with : cone 60°resist compression design 3. 100% TIG welding with pure argon gas shield 4. Interior Finish: Sanitary 2B finish 5. Exterior Finish: Oil brushed finish 6. Interior full polished to 0.4 μm 7. Insulated with Polyurethane foam 80mm 8. TC connected CIP arm with 360° coverage spraying ball 9.Full sanitary metallic sealed sampling valve 10.Pressure relief valve PVRV 2 bar on CIP arm 11.Hydraulic shock pressure gauge on CIP arm 12.Rotating racking arm 13.Thermowell for high accuracy temperature sensor 14.Dry hopping port 4” TC with solid end cap |

Other necessory system of craft microbrewery equipment

| Miller system:Breaker Roll Type; Adjustable mill degree; |  |

| Cooling system:Glycol water tank; Cold water tank; Chiller; Circulation pump | |

| CIP system:Alkali tank; sterilization tank; pump | |

| Control system:PLC Control or PID control,Siemens,Omron,Schneider,Danfoss component |

Company information

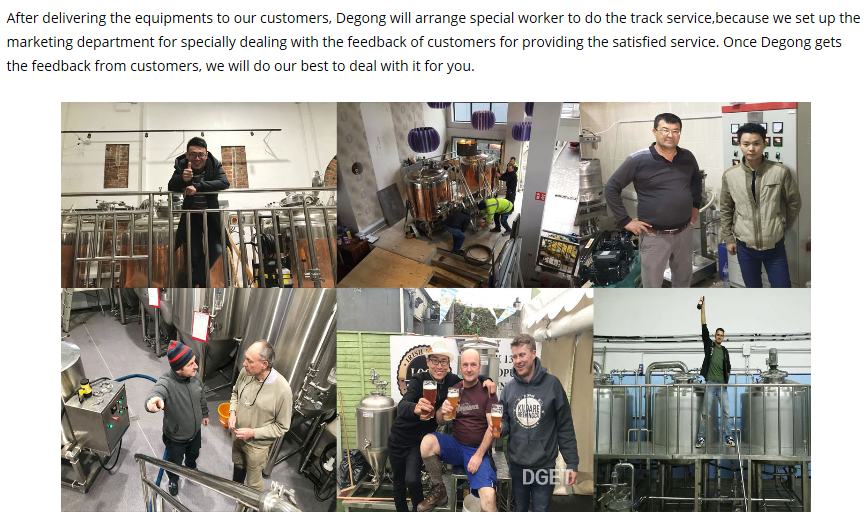

Weather you want to brew craft beer or brew commercial/industrial beer,weather you want to start a new beer brewery project or expand your brewing scale.No matter what you want to brew lager or ale, stout beer or light beer,barley beer or wheat beer,fruit beer or corn beer,low concentration beer or high concentration beer….DEGONG brewing equipment always can meet your requirement.