Description

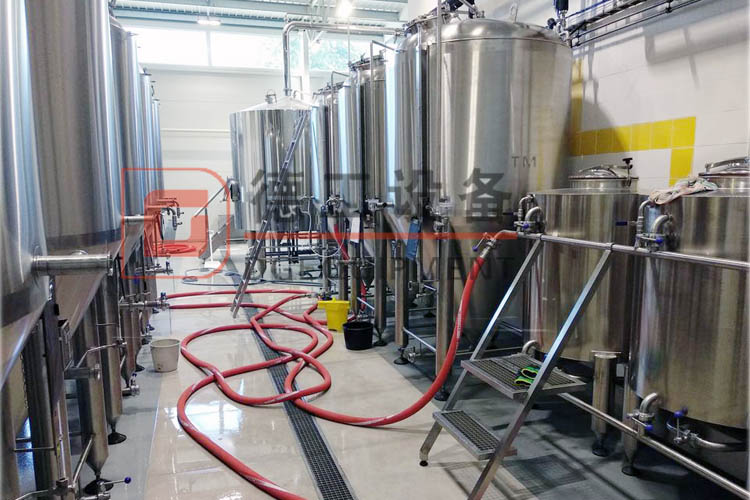

20BBL Steam Heating Brewing Equipment is made of stainless steel reaching international standard level ,the appearance of other imported German technology, decorative and practical. laser cutting line and pure argon gas welding. polyurethane moisturizing measures. so that the temperature and room temperature device surface consistent.The whole equipment and the layout of pipellnes looks very beautiful without the dead corner.

Main configuration of beer brewery equipment

Brewhouse unit

For 10BBL brewery equipment brewhouse unit, we recommend 3-vessel( mash lauter tun + boiling whirlpool tun + hot water tank)

About steam heating: it needs a bolier. The bolier can be electric bolier, gas bolier, diesel boiler. It is one of the most stable heating method.

1- Mash / Lauter Tun

Used to combine grist and hot water. A false bottom is then used to extract the clear wort from the malted barley. The spent grains left over can be used for animal feed.

2-Brew kettle / Whirlpool

The wort is boiled to a desired specific gravity and hops are added for flavor and bitterness. After boiling the wort is whirlpooled to collect soluble proteins in the center of the kettle.

3-Hot Liquor Tank(We recommend using a hot water tank of the same volume or twice)

Used to recover energy and heat the water (liquor) needed for recirculation and sparging water onto the grain bed to convert starches to sugar.

Fermentation vessel

| Configuration | Equipment details |

| Fermentation tank(FV) |

Feature:

Technology paremeters:

Fermentation accessories Breather valve, mechanical regulation valve, raking arm, ice water solenoid valve, sample valve, side/top manhole, temperature probe(PT100) |

| Bright beer tank(BBT) |

Feature:

Technology parameters

Bright beer tank accessories Top manhole, breather valve, cleaning ball, sampling valve, mechanical regulation valve, temperature probe(PT100), adjustable foot, legs. |

| Yeast adding tank |

Stainless steel 304 fine polished process |

| Control system |

Electrical controlling cabinet with temperature, on-off controlling for brewhouse Electrical controlling cabinet with temperature, on-off controlling for cooling parts Temperature controller, thermocouple, solenoid valves etc PLC with touch screen panel for special request |

| Cooling system |

Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing Efficiency chillers or refrigerators with fryonto supply cooling energy Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger All pipes, fitting, insulation materials |

Fermentation tank details

Bright beer tank details

Additional system

Mill unit

Malt crushing equipment use disc type mill or roller mill.The size of particle can be adjusted.

Control system

VFD control method: Control the fermenter and brite beer tank and brewhouse by temperature.

Fully automatic control method: means all things is automatic. the valves are all pneumatic, The raker and blender of the lauter tun and kettle can be hydraulic control, the milling system is also automatic.

CIP system

Alkali tank, mini control panel and heating coil in one tank

CIP system

If you want to order brewery equipment, please get in touch with me.